DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 31 of 52

flowserve.com

i)

Remove pump casing gasket [4590.1] and discard.

A replacement gasket will be required for assembly.

j)

Clean gasket mating surfaces.

6.8.2

Impeller removal

NEVER APPLY HEAT TO REMOVE THE

IMPELLER. TRAPPED OIL OR LUBRICANT MAY

CAUSE AN EXPLOSION.

Impeller removal with threaded on

6.8.2.1

impeller

a) Ensure the pump bearing housing assembly is

firmly fixed to the work bench.

b) Fit a chain wrench or bolt a bar to the holes in the

coupling half, or fit a keyed shaft wrench directly

to the shaft. Make sure the wrench or bar can

not slip.

c) Turn the shaft [2100] counter-clockwise as viewed

from the drive end of the shaft with the wrench.

d) Give the shaft a quick turn clockwise to sharply

strike the wrench handle against the work bench

surface or a wooden block. A few sharp strikes

by the handle onto the bench/wooden block will

free the impeller from the shaft.

e) Alternatively, twist the impeller by firmly grabbing

hold of the impeller and twist it counter-clockwise.

To make the wrench handle impact on the work

bench. This method requires the use of metal

mesh reinforced gloves.

f) Remove and discard the impeller O-ring [4610.1].

Use a new O-ring for assembly.

Impeller removal with key drive impeller

6.8.2.2

c) Remove impeller nut [2912.1/2912.2] complete with

O-ring [4610.5], which should be discarded. (A new

O-ring will be required for assembly.)

d) Pull impeller [2200] off shaft [2100].

e) Remove impeller key [6700.2].

f)

Remove impeller sealing gasket [4590.4] and

discard. (A new sealing gasket will be required for

assembly.)

6.8.3

Cover and seal

The seal manufacturer's instructions should be followed

for dismantling and assembly, but the following

guidance should assist with most seal types:

a) Remove shaft guard (if fitted).

b) Remove the seal gland nuts, if a separate seal

gland is fitted, and slide the seal gland away.

c) Remove the two cover nuts [6580].

d) Loosen the grub screws (used in most

mechanical seals).

e) Carefully pull off the cover and mechanical seal

rotating element(s).

f) Remove the seal cover.

g) Remove shaft sleeve (if fitted).

h) On non-cartridge seals the stationary seat

remains in the cover/mechanical seal gland with

its sealing member. Remove only if damaged or

worn out.

i)

On pumps fitted with gland packing, the packing

and lantern ring should be removed only if the

packing is to be replaced.

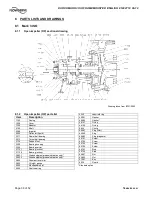

6.8.4

Bearing housing

a) Take grub screw(s) out of the pump half coupling

and pull off this coupling and remove the coupling

key.

b) Remove support foot [3134] (if necessary).

c) Remove the pump side liquid deflector [2540]

and/or labyrinth seal rotary half (depending on

option fitted).

d) Slacken the bearing carrier screws to initiate

bearing carrier release.

e) Remove bearing carrier [3240] and shaft [2100]

assembly from the bearing housing [3200] by pulling it

towards the coupling end.

f) Remove bearing circlip [6544] (or bearing lock

nut [3712.2] if paired angular contact bearings

are fitted).

Bearing carrier locking rings are left-

hand thread.

g) Remove drive side v-ring [4305] and/or labyrinth

seal rotary half (depending on option fitted).

h) Remove bearing carrier [3240].

i)

Remove pump side bearing [3011].

j)

Release the self-locking drive side bearing nut

[3712.1] and remove drive side bearing [3013].

k) When pressing bearings off the shaft, use force

on the inner race only.

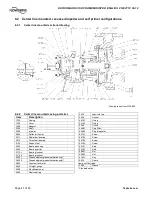

6.9 Examination of parts

Used parts must be inspected before

assembly to ensure the pump will subsequently run

properly. In particular, fault diagnosis is essential to

enhance pump and plant reliability.

6.9.1

Casing, cover and impeller

Inspect for excessive wear, pitting, corrosion, erosion

or damage and any sealing surface irregularities.

Replace as necessary.

6.9.2

Shaft and sleeve (if fitted)

Replace if grooved or pitted. With the bearing

mounting diameters (or bearing outer) supported by

V-blocks, check that the shaft runouts are within

0.025 mm (0.001 in.) at the coupling end and

0.050 mm (0.002 in.) at the sleeve/impeller end.

Summary of Contents for Durco Mark 3

Page 49: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 49 of 52 flowserve com Notes ...

Page 50: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 50 of 52 flowserve com Notes ...

Page 51: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 51 of 52 flowserve com Notes ...