DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 33 of 52

flowserve.com

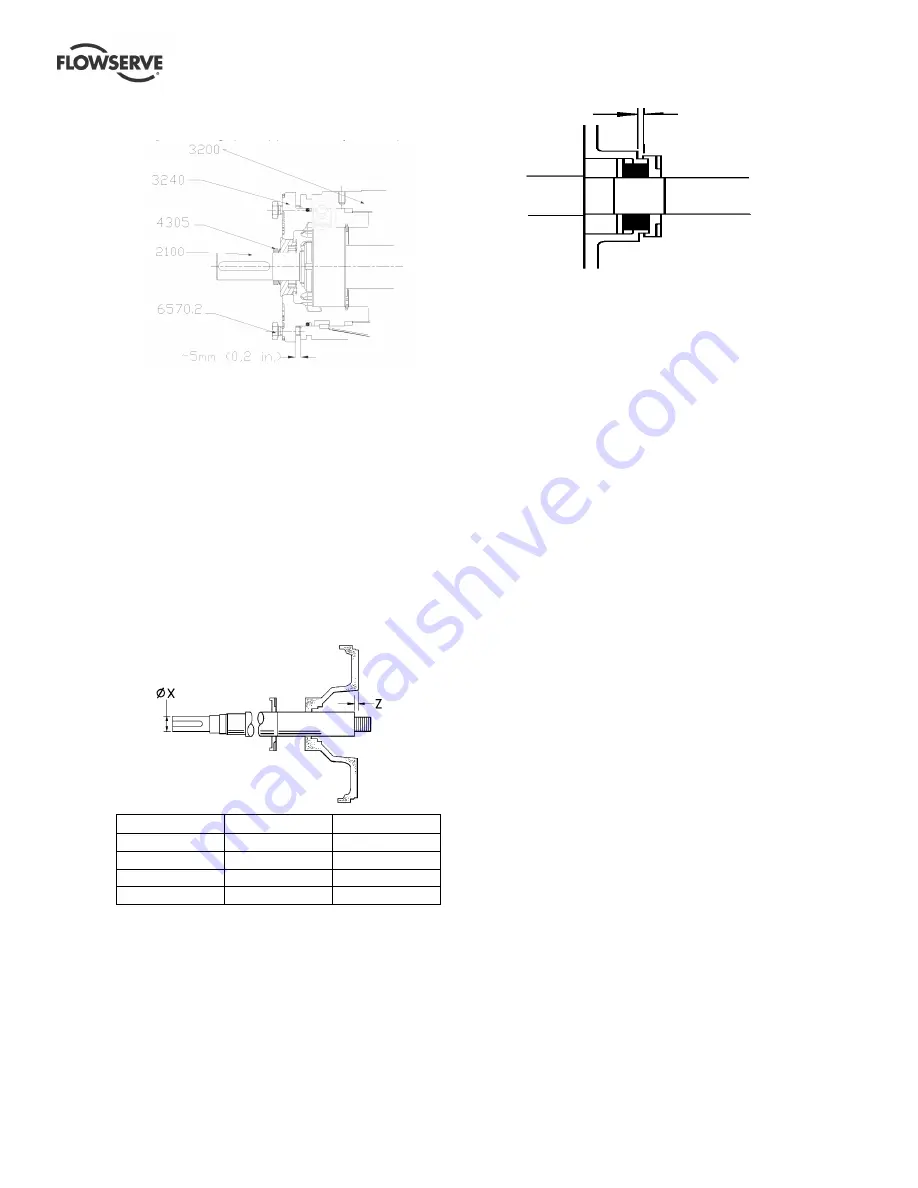

o) Install the shaft assembly into the bearing housing

[3200] until the gap is approximately 5 mm (0.2 in.).

p) Fit the bearing carrier screws [6570.1] but do not

tighten.

q) Press drive side v-ring [4305] and pump side

liquid deflector [2540] onto shaft [2100] where

applicable. The V-ring type shall be fitted with

light contact with the bearing carrier [3240].

r) The pump side deflector [2540] (this feature is

integral with some proprietary labyrinth seals)

should only be set in its final position after setting

the shaft axial position.

s) Temporarily fit the cover [1220] to the power-end.

The cover, above 125 size, is retained by studs

[6580] and their nuts. The shaft [2100] may now

be positioned in relation to the cover face, by

rotating the carrier, position as shown below:

Bearing housing

Dia. X mm (in.)

Z mm (in.)

Frame 1

24 (0.945)

9 (0.354)

Frame 2

32 (1.260)

17 (0.669)

Frame 3

42 (1.654)

9 (0.354)

Frame 4

48 (1.890)

22 (0.866)

t) The pump side deflector [2540] may then be

moved towards the bearing housing [3200] and

set with its clearance.

0.5 to 2 mm

(0.02 to 0.08 in.)

6.10.2 Seal cover and seal assembly

a) Extreme cleanliness is required. The sealing

faces and shaft [2100] or sleeve [2400] surface

must be free from scratches or other damage.

b) Refer to section 6.11, Seal arrangements for seal

diagrams.

c) Carefully press the stationary seat into the cover

[1220] or mechanical seal cover [4213], ensuring

that the seating ring is not deformed. Where an

anti-rotation pin is fitted ensure that correct

engagement with the slot is achieved.

d) Place any separate seal covers over the shaft

[2100].

e) Refer to manufacturer's instructions to position

the mechanical seal rotating elements. Tighten

any drive screws in the seal drive collar. For

precise compression most cartridge seals should

be set after complete pump assembly.

f) Fit the cover [1220] into the bearing housing

[3200] and tighten all fasteners.

6.10.3 Gland packed stuffing box assembly

a) Assemble the gland packing [4130] into the cover

before fitting on to the shaft [2100], see 6.11.6.

b) Stagger the joints in the gland packing by 90

degrees to each other.

c) The lantern ring halves [4134], if required, should

be positioned mid-way along the packing.

d) Position the gland [4120] squarely against the last

ring and tighten the gland nuts finger-tight only.

Install into bearing housing assembly, fit the two

studs and nuts to hold the cover [1220] in place.

e) Check that the shaft [2100] rotates freely.

6.10.4 Impeller assembly and setting

Impeller assembly and setting

6.10.4.1

a) Fit a new O-ring [4610.1] into the impeller [2200]

using a small amount of grease to hold it in place.

Apply anti-galling compound (which does not

contain copper) to the impeller thread to help

subsequent removal.

b) Assemble impeller [2200] onto the shaft [2100].

c) Tighten the impeller. Use the same method as in

disassembly but rotating in opposite direction. A

few sharp strikes will tighten it to the correct level.

Summary of Contents for Durco Mark 3

Page 49: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 49 of 52 flowserve com Notes ...

Page 50: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 50 of 52 flowserve com Notes ...

Page 51: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 51 of 52 flowserve com Notes ...