ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 13 of 37

A crane must be used for all pump sets in

excess of 25kg (55lb). Fully trained personnel must

carry out lifting, in accordance with local regulations.

The driver and pump weights are recorded on their

respective nameplates.

2.4 Storage

If the unit will not be put immediately into service, it

should be stored in a dry room. To avoid any damage

during the storage period, the influence of any low or

high frequency vibration must be totally inhibited. If

the pump is delivered sealed in a plastic-wrapper, it is

of max. importance to avoid any damage of that

wrapper, because this will protect the pump against

humidity. Therefore it must be checked if this wrapper

has become cracked and if so, the wrapper must be

renewed.

2.4.1 Long period storage

If the pump is delivered in a plastic bag, the

preservations stands up for one year. If the storage

period exceeds this time, the preservation must be

checked and renewed. Also the air tight plastic bag

must be changed. Moreover we recommend to order

a Flowserve Service Engineer for checking the pump

before the first start up.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local regulations. If the

product contains substances, which are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances are

disposed of safety and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3.0 DESCRIPTION

3.1 Configuration

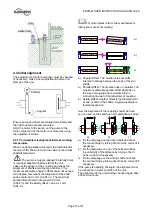

The model ERPN-M belongs to Flowserves family of

API 685 magnetic driven end suction pumps.

The pump line is based on a modular system, thus

providing maximum design and operating flexibility.

The pump is available with several impeller designs.

•

closed impeller with front and back wear rings.

Above a certain size the axial thrust is balanced

by balancing holes.

•

semi open impeller with back vanes for abrasive

fluids

•

free flow (recessed) impeller for fluids containing

fibre

All three impeller versions can be combined with an

inducer for low NPSHA applications.

For high suction pressure applications the balance

holes are seized individually to ensure a trouble-free

operation.

The sense of rotation of the pump is

clockwise (CW), looking from the coupling to the shaft

end of the pump.

3.2 Nomenclature

Example:

ERPN-M 150-200 – X-Ind.

150

Discharge nozzle in mm

200

max. impeller size in mm

Ind

Inducer

X:

S

high suction pressure

O

semi open impeller

F

free flow impeller

3.3 Design of major parts

3.3.1 Bearing housing

Made of carbon steel. It is flanged to the pump casing

and provides enough space for mechanical seals

according to API 682.

3.3.2 Pump casing

The pump casing is of volute type. For larger sizes

double volute design is used to minimize radial

forces. Back pull out design for easy maintenance, so

the casing remains on its foundation in case of repair.

3.3.3 Hydraulics

3.3.3.1 Closed impeller

This is the standard version. Both, the impeller and

pump casing have renewable front and back wear

rings. Above a certain impeller size, the axial thrust is

balanced by balancing holes.

3.3.3.2 Free flow impeller

The impeller has straight radial vanes and is mounted

recessed in the pump casing. The axial thrust is

balanced by back vanes.