ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 18 of 37

If the pump is fitted with a Constant Level

Oiler type "ADAMS", no adjustment of the oil level is

possible.

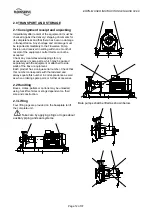

5.2.4.2 Adjusting of DENCO Constant Level Oiler

If the pump is fitted with a Constant Level Oiler type

„DENCO“, the correct oil level has to be checked after

fitting the pump! Dimension

a

is the distance from the

centerline of the pump to the minimum oil level (marks

at the bearing housing).

1

Denco Oiler

2

lock nut

3

adjusting sleeve

4

oil sight glass

5

oil drain

6

distance sleeve

a) The oil level may be „fine tuned“ by turning the

adjusting sleeve (3) and finally locked into

position by tightening the lock nut (2). To

replenish, the reservoir and adaptor (1) may be

removed by sliding it out of the body, removing

the adaptor and fill the reservoir. Fully reinserting

the adaptor / reservoir into the body ensures the

previously adjusted oil level is maintained. The

oiler is equipped with an overflow tube to avoid a

rise of the oil level. This is necessary to maintain

a constant level in an oil bath lubrication system,

where an oil mist is used as primary lubrication.

The oiler is preadjusted with the distance

sleeve [6], therefore no adjustment is required

anymore.

b) Additionally you can check the correct oiler

adjustment by an oil sight glass (correct oil level

is the middle of the oil sight glass).

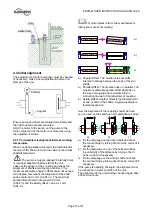

Size of

Bearing

Frame

Cylindrical roller

bearing [476]

Angular contact ball

bearing [477]

Dimension

„a“ mm (in)

1

NU 207

7306 BECB (J),(M)

28 (1.1)

2

NU 309

7309 BECB (J),(M)

40 (1.58)

3

NU 311

7311 BECB (J),(M)

49 (1.93)

4

NU 313

7313 BECB (J),(M)

57 (2.24)

5

NU 315

7315 BECB (J),(M)

65 (2.56)

6

NU 317

7317 BECB (J),(M)

72 (2.84)

Refer to nameplate or part list, to reading

the correct frame size.