ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 27 of 37

6.6 Setting impeller clearance

No axial adjustment of the rotor is necessary.

6.7 Disassembly

Refer to section 1.6,

Safety

, before

dismantling the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawings for part numbers and

identification.

6.7.1 Dismantling of pump

1)

Completely drain the pump by using the drain

connection. By pumping explosive or toxic media,

flush your system with Nitrogen.

2)

Remove coupling guard and uncouple the pump

from the motor. Pull off the coupling hub from the

pump shaft [415] and take out the key [422].

Ensure that the motor is

locked against start up.

If applied pull off the vane.

3)

Drain the oil from the bearing housing, using the

drain connection [206]. If required disconnect all

auxiliary pipings and auxiliary devices like

vibration probes, temperature probes, ect.

4)

Loose hex nuts [0291] at the pump casing and the

hex nuts of the wobble plate [488] for the

baseplate. Now you can pull out the complete

pump assembly from its casing.

Larger pumps are equipped with

jack screws [306] to pull out the pump assembly.

Be sure that the two pins

[044] are screwed in the casing for guiding the

outer rotor assembly during pulling off.

6.7.2 Dismantling of the outer rotor

1) Take out the casing gasket [398] located between

the secondary containment [471] and the pump

casing cover [470].

The casing gasket [398] shall be

renewed after each disassembly. Now the outer

rotor can be dismantled.

2) Remove retaining ring for shaft [4651] and pull

outer rotor of magnetic coupling [M02] inclusive

driving flange [465] from driving shaft [415].

Pay attention that the magnets

of outer rotor [M02] will not be damaged.

Afterwards remove keys [423].

3) Loose socket screws [021] to separate mechanical

seal unit from barrel [471] and pull it of the driving

shaft [415].

4) Now disassemble carefully seal end plate [506]

inclusive gasket [495], cylindrical pin [524] and

stationary seal ring [G01] together with stationary

seal ring packing [G03] and throttle ring [G02] from

barrel [471].

5) Furthermore pull off shaft sleeve [509] with O-ring

[450] and whole rotating unit of mechanical seal

[G04, G05, G06, G07] from driving shaft [415].

6) Next loose the hex nuts [035] of studs [034] and

separate bearing housing [470] from barrel [471].

Pay attention to O-ring [494]

which has to be renewed after every dismantling to

assure security of pump.

7) Now line bearing cover [478] together with shaft

seal [4781] can be separated from barrel [471] by

loosening the socket screws [021]. Check whether

the guard ring is worn and has to be changed.

8) Loose hex screw [031] from thrust bearing cover

[479] and pull it together with O-ring [493] and

labyrinth-type seal [4791] from bearing housing

[4791] respectively from driving shaft [415].

9) Now you can carefully pull driving shaft [415]

inclusive cylindrical roller bearing [476], deep

groove ball bearing [477], locking plate [464] and

locking nut [463] towards coupling hub out of

bearing housing [470].

10) Bend locking plate [464] and loose locking nut

[463] from shaft.

11) Pull off deep groove ball bearing [477] from driving

shaft [415] with the aid of a puller and check

whether the inner ring of cylindrical roller bearing

has to be renewed, too. There are two possibilities

to remove it from driving shaft [415].

Heat up inner ring uniformly by welding torch or

blowtorch until it slips from shaft. Take care that the

shaft stays as cold as possible because otherwise

it will get distorted.

Transport the shaft to a work bench and turn the

inner ring from shaft if there is no other possibility to

remove it.

12) Squeeze roller bearing [476] without inner ring out

of bearing housing [470].

13) Check retaining ring for bore [4761] against any

damage.

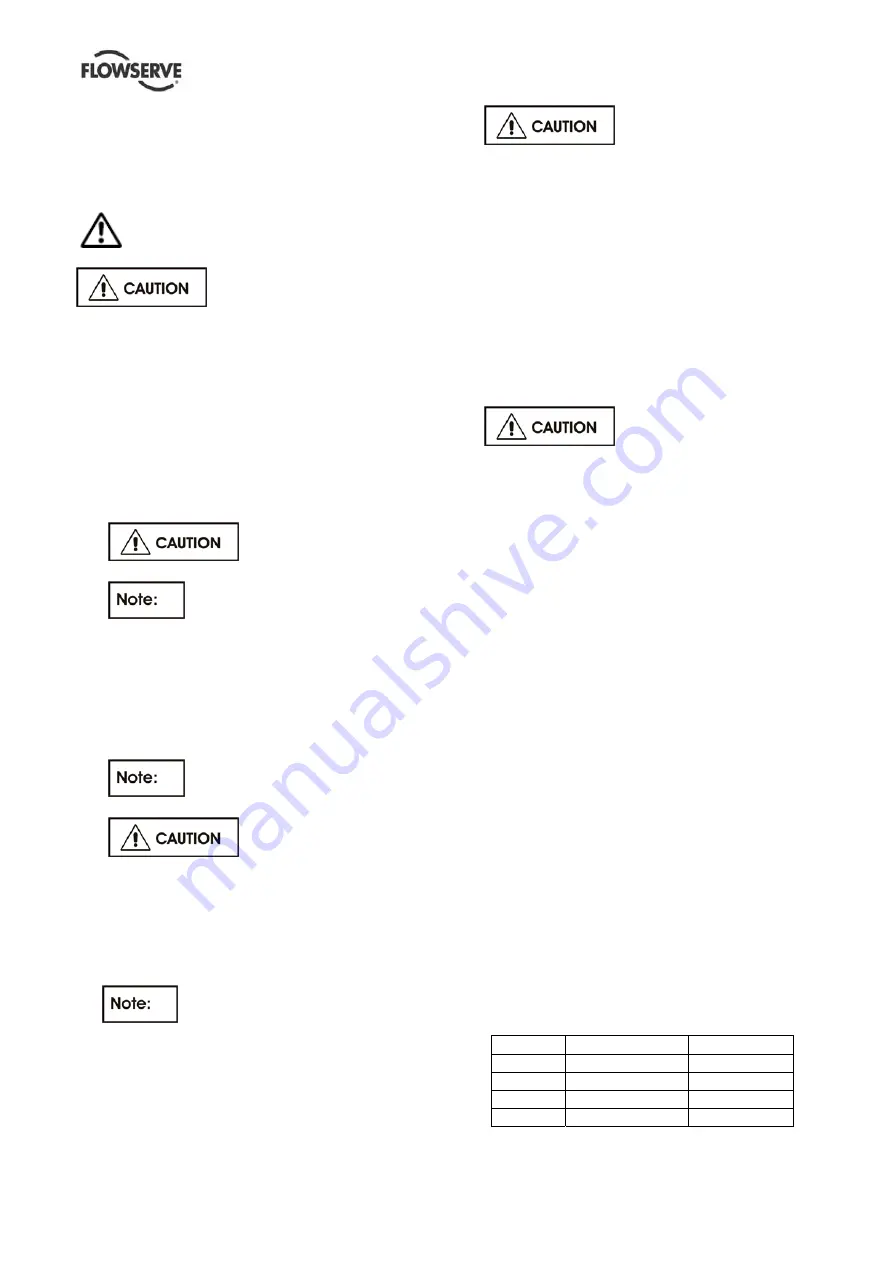

Frame

Thrust bearing

Line bearing

1

6306 – C3

NU 207

2

6306 – C3

NU 207

3

6309 – C3

NU 209

4

6309 – C3

NU 209