ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 33 of 37

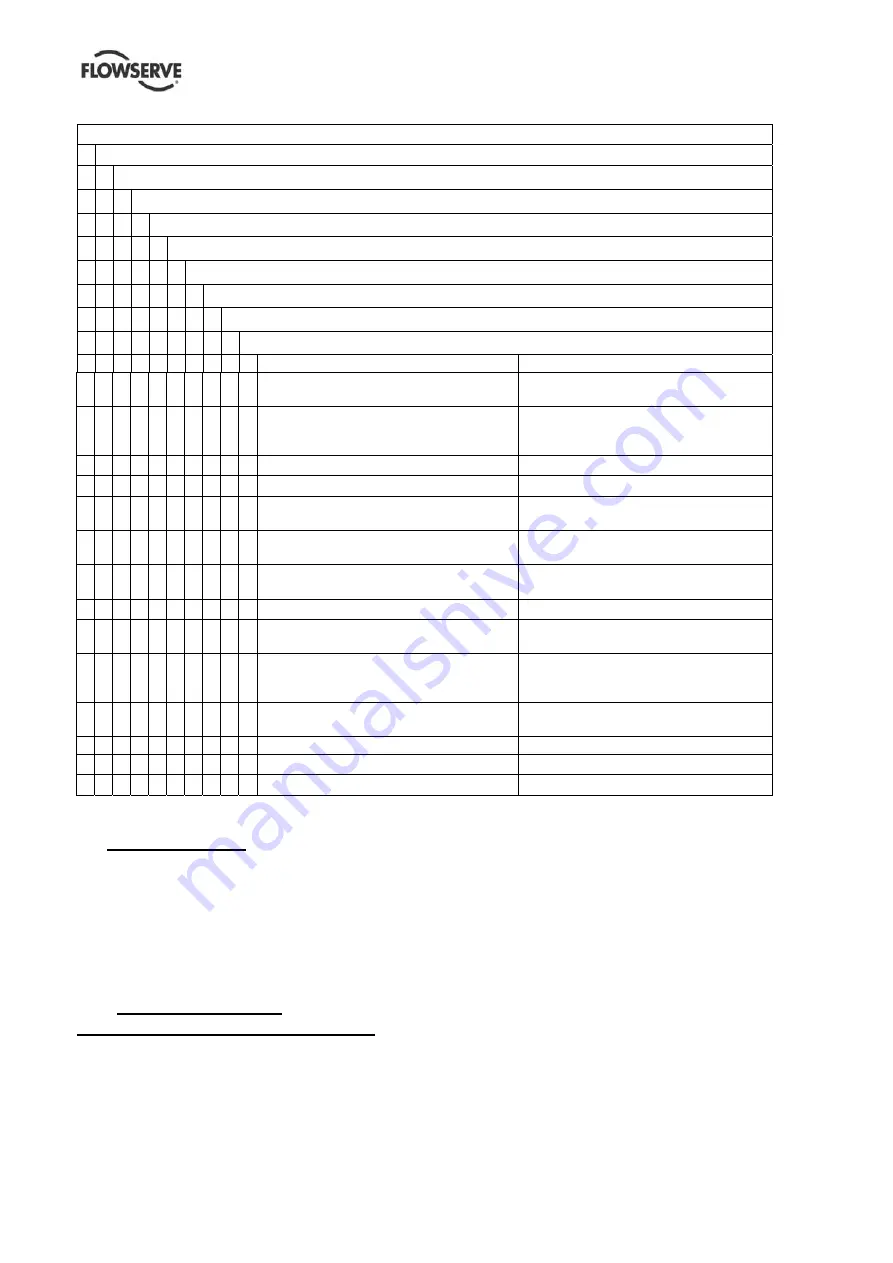

FAULT SYMPTOM

Pump overheats and seizes

⇓

⇓

Bearings have short life

⇓

⇓

Pump vibrates or is noisy

⇓

⇓

Magnetic coupling has short life

⇓

⇓

Magnetic coupling leaks excessively

⇓

⇓

Pump requires excessive power

⇓

⇓

Pump loses prime after starting

⇓

⇓

Insufficient pressure developed

⇓

⇓

Insufficient capacity delivered

⇓

⇓

Pump does not deliver liquid

⇓

⇓

PROBABLE CAUSES

POSSIBLE REMEDIES

z

z

z

Incorrect type of magnetic coupling

for

operating conditions.

Consult Flowserve

z

z

z

z

z

Shaft running off centre because of worn

bearings or misalignment.

Check misalignment and correct if necessary.

If alignment satisfactotry check bearings for

excessive wear

z

z

z

z

z

Impeller out of balance resulting in vibration.

Check and consult Flowserve

z

z

z

Abrasive solids in liquid pumped.

Check and consult Flowserve

z

z

Magnetic coupling

was run dry.

Check mechanical seal condition and source

of dry running and repair

z

z

Internal misalignment due to improper repairs

causing impeller to rub.

Check method of assembly, possible damage

or state of cleanliness during assembly

z

z

z

Excessive thrust caused by a mechanical

failure inside the pump.

Check wear condition of Impeller, its

clearances and liquid passages

z

z

Excessive grease in ball bearings.

Check method of regreasing

z

z

Lack of lubrication for bearings.

Check hours run since last change of

lubricant, the schedule and its basis

z

z

Improper installation of bearings

Check method of assembly, possible damage

or state of cleanliness during assembly and

type of bearing used

z

z

Damaged bearings due to contamination.

Check contamination source and replace

damaged bearings

C. ELECTRICAL TROUBLES

z

z

z

z

Wrong direction of rotation.

Reverse 2 phases on motor terminal box

z

z

z

Motor running too slow,

Check motor terminal box connections

9.0 CERTIFICATION

Certificates determined from the contract

requirements are provided with these instructions

where applicable. Examples are certificates for CE

marking, ATEX marking etc. If required, copies of

other certificates sent separately to the Purchaser

should be obtained from the Purchaser for retention

with these User Instructions.

10.0 OTHER RELEVANT

DOCUMENTATION AND MANUALS

10.1 Supplementary user instructions

Supplementary instructions determined from the

contract requirements for inclusion into user

Instructions such as for a driver, instrumentation,

controller, sub-driver, seals, sealant system, mounting

component etc are included in the Data Book. If

further copies of these are required they should be

obtained from the supplier for retention with these

user instructions.

Where any pre-printed set of user instructions are

used, and satisfactory quality can be maintained only

by avoiding copying these, they are included at the

end of these user instructions such as within a

standard clear polymer software protection envelope.

10.2 Change notes

If any changes, agreed with Flowserve Pump

Division, are made to the product after its supply, a

record of the details should be maintained with these

User Instructions.