ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 6 of 37

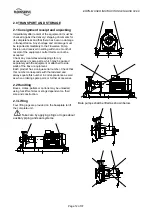

run-up process (See section 5

Commissioning,

startup,

operation and shutdown).

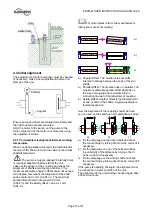

NEVER RUN THE PUMP DRY

INLET VALVES TO BE FULLY

OPEN WHEN PUMP IS RUNNING

Running the pump at zero flow or below the

recommended minimum flow continuously will cause

damage to the magnets and/or bearings.

INLET VALVES TO BE FULLY

OPEN WHEN PUMP IS RUNNING

Running the pump at zero flow or below the

recommended minimum flow continuously will cause

damage to the seal.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a

flow rate with no back pressure on the pump may

overload the motor and cause cavitation. Low flow

rates may cause a reduction in

pump/bearing life,

overheating of the pump, instability and

cavitation/vibration.

When ambient temperatures are

likely to drop below freezing point, the pump and any

cooling and flushing arrangements must be drained

or otherwise protected.

HIGH MAGNETIC FIELDS

Persons working with permanent parts must be made

aware that there is a potential danger from magnetic

fields e.g. influence on heart pacemakers, credit

cards, computers, computer tapes/discs and

watches.

Great care must be taken when working with or

assembling/ dismantling magnetic rotors because of

the very high forces which can be created by the

magnets.

When shipping raw or bare magnet assemblies,

especially by air, special precautions may be

necessary.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lbs) use a crane

corresponding to the mass and in accordance with

current local regulations.

NEVER DO MAINTENANCE WORK WHILST THE

UNIT IS CONNECTED TO POWER

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate sitting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive strict safety procedures

must be applied.

Gland Packing must not be used when pumping

hazardous liquids.

DRAIN PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted)

When a pump has experienced temperatures over

250 °C (482 ºF), partial decomposition of fluoro-

elastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

GUARDS MUST NOT BE REMOVED WHILE

PUMP IS OPERATIONAL

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should be

avoided.

NEVER APPLY HEAT TO REMOVE

IMPELLER

Trapped lubricant or vapour could cause an

explosion.

HOT AND COLD PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators, they

must

be shielded to avoid accidental contact. If

complete protection is not possible, the machine

access must be limited to maintenance staff only.

Note: bearing housings must not be insulated and

drive motors and bearings may be hot.

If the temperature is greater than 68 °C (175 °F) or

below 5 °C (20 °F) in a restricted zone, or exceeds

local regulations, action as above shall be taken.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

•

Avoid excess temperature