FP USER INSTRUCTIONS ENGLISH 71576286 - 07/06

Page 10 of 35

In areas where the staff has to intervene, remember

that when the level of the sound pressure is:

Below 70 dBA :It is not necessary to take

special precautions.

Above 70 dBA :People working continuously in

the machine room m ust be

supplied with protective devices

against noise.

Below 85 dBA :No particular measures need to

be taken for casual visitors

staying in the room during a

limited period.

Above 85 dBA :The room must be considered as a

dangerous area because of the

noise and a warning sign must be

fixed at each entry warning the

people coming into the room, even

for a short period, that they must

wear hearing protection.

Above 105 dBA:Special hearing protection adapted

to this noise level and to the

spectral noise components must

be installed and a warning sign to

this effect erected at each entry.

The staff in the room must wear

ear protection.

Make sure that the noise, which travels through the

walls and windows, does not generate too high

noise levels in the machine room's surroundings.

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping

documents for its completeness and that there has

been no damage in transportation.

Any shortage and or damage must be reported

immediately to Flowserve Pump Division and

received in writing within one month of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes and wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to

sidewalls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

2.2.1 General instructions concerning handling

Boxes, crates, pallets or cartons may be unloaded

using forklift vehicles or slings dependent on their

size and construction. See 2.3.1 for positioning of

slings.

To lift heavy pieces above 25 kg (55 lb), use a winch

adapted to the mass and in accordance with the

current local regulations.

To lift machines or pieces with one or several

suspension rings, only use hooks and chains in

compliance with the local regulations concerning

safety. Never put cables, chains or ropes directly on

or in the suspension rings. Cables, chains or lifting

ropes must never present excessive bending.

Never bend the lifting hooks, suspension rings,

chains, etc., which should only be made to endure

stresses within, calculated limits. Remember that the

capacity of a lifting device decreases when the

direction of the lifting force direction makes an angle

with the device axis.

To increase the safety and the efficiency of the lifting

device, all the lifting elements must be as

perpendicular as possible. If necessary a lifting

beam can be placed between the winch and the

load.

When heavy pieces are lifted up, never stay or work

under the load or in the area, which could be in the

path of the load if it were to swing or fall away.

Never leave a load hanging from a winch. The

acceleration or the slowing-down of lifting equipment

must stay in the safety limits for the staff. A winch

must be positioned in such a way that the load will

be raised perpendicularly. Where possible

necessary precautions must be taken to avoid the

swing of the load, using for example two winches

making approximately the same angle, below 30°,

with the vertical.

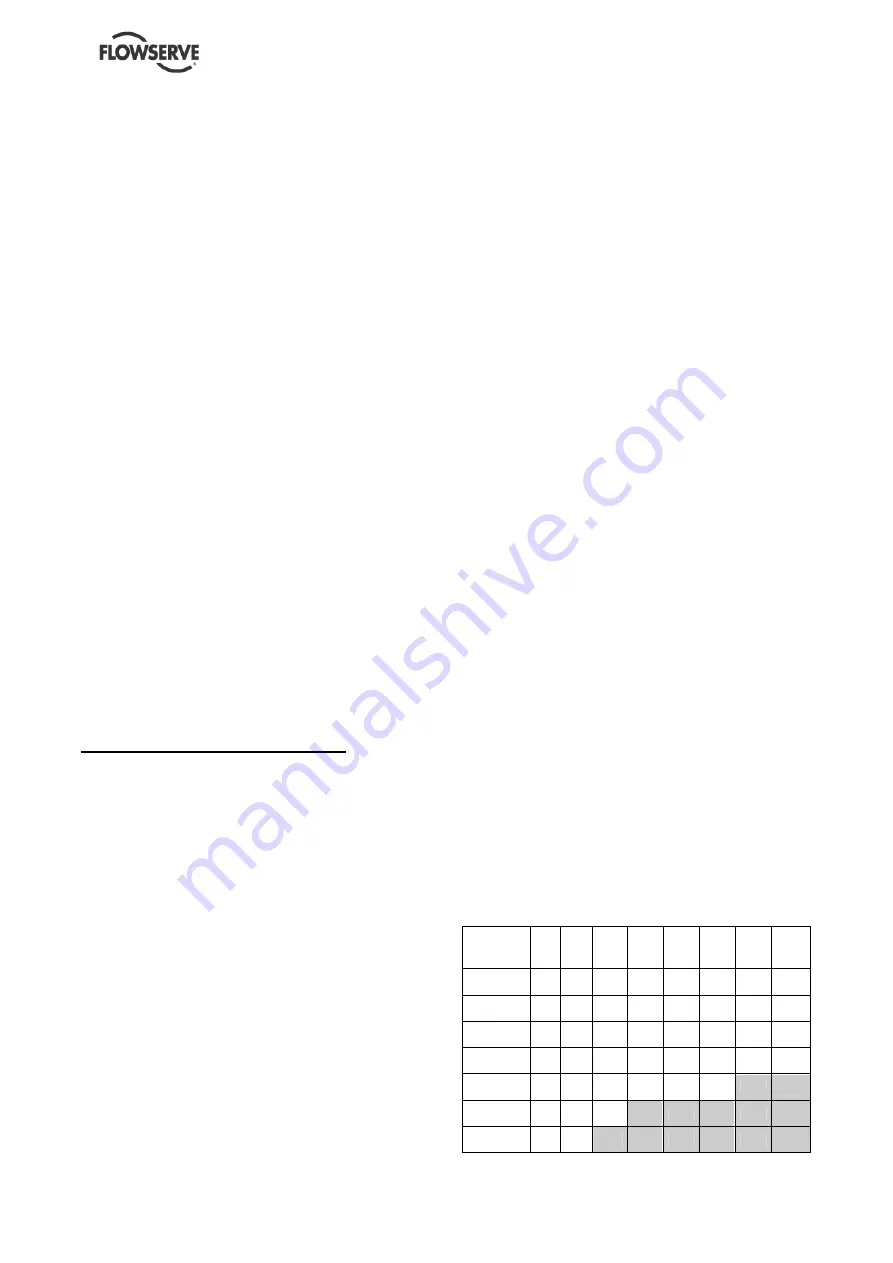

2.2.2 Pump masses

All masses are in kg:

Mass of

bareshaft

pump

50

FP

65

FP

80

FP

100

FP

122

FP

125

FP

152

FP

202

FP

1 stage

37

54

78

80

204

205

530

600

2 stages

37

54

92

94

243

240

605

720

3 stages

42

61

106

108

282

275

680

840

4 stages

47

68

120

122

321

310

755

960

5 stages

52

75

134

136

360

345

6 stages

57

82

148

7 stages

62

89