FP USER INSTRUCTIONS ENGLISH 71576286 - 07/06

Page 25 of 35

6.3.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of

metallic surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

6.4 Recommended spares and

consumable items

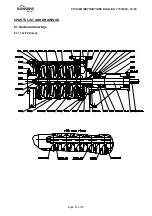

50 FP, 65 FP, 80 FP, 100 FP, 125 FP

: [2250] -

[3011-01] - [3011-02] - [4130] - [4590] - [4610]

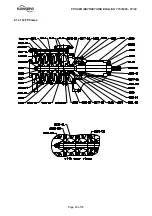

122 FP, 152 FP, 202 FP

: [2250] - [3011-01] - [3011-

02] - [4130] - [4590-01] - [4590-02] - [4610-01] -

[4610-02] - [4610-03] - [4610-04]

a) Destroy all the gaskets after dismantling, replace

them when reassembling.

b)

IT IS RECOMMENDED THAT

BEARINGS ARE NOT REUSED AFTER ANY

REMOVAL FROM THE SHAFT.

c)

After serving during two years, replace the gland

packing.

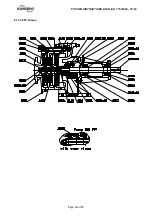

6.5 Disassembly

Refer to section 1.6,

Safety

, and section 6

Maintenance

, before dismantling the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available. Refer to sectional drawings for

part numbers and identification.

REPAIR OF THE PUMP

If the pump presents abnormalities or a

persistent malfunction, contact immediately:

FLOWSERVE

After-sales Service

Tel.: 02 43 40 57 57

(33) 2 43 40 57 57

Fax.: 02 43 40 58 17

(33) 2 43 40 58 17

According to the After-sales Service instructions,

disassembly will be limited to the dismantling of the

pump:

a)

DISCONNECT THE UNIT FROM

POWER.

b) Close the inlet valve (if fitted) and outlet valve

.

c)

Wait for the moment when the pump casing is

cooled and at ambient temperature.

d)

DRAIN PUMP.

e) Dismantle inlet and outlet pipeworks as well as

all pipeworks.

f)

REMOVE PUMP TAKING INTO

ACCOUNT SAFETY (§ 1) AND HANDLING

(§ 2.2) PROCEDURES.

ANY DISASSEMBLY, REPAIR OR

REASSEMBLY WILL BE CARRIED OUT UNDER

FLOWSERVE' RESPONSABILITY, EITHER

DIRECTLY BY THE AFTER-SALES SERVICE OR

BY OTHER FLOWSERVE-AGENTS WHO WILL

GET THE REQUIRED INSTRUCTIONS AND

APPROVALS. THIS IS THE CASE OF

AUTHORIZED REPAIRERS WHOSE ADDRESSES

AND TELEPHONE NUMBERS WILL BE GIVEN

ON REQUEST.