FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 11 of 60

flowserve.com

®

The noise level of machines in this range will most likely be of values which require noise exposure control, but typical val ues are

inappropriate.

Note:

For 880 and 720 r/min reduce 980 r/min values by 2 dBA

.

2 TRANSPORT AND STORAGE

2.1

Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for its

completeness and that there has been no damage in

transportation. Any shortage and/or damage must be

reported immediately to Flowserve Pump Division and

must be received in writing within one month of receipt

of the equipment. Later claims cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side walls

of the box or equipment.

Each product has a unique serial number. Check that

this number corresponds with that advised and always

quote this number in correspondence as well as when

ordering spare parts or further accessories.

2.2

Handling

Boxes, crates, pallets or cartons may be unloaded

using fork

-

lift vehicles or slings dependent on their size

and construction.

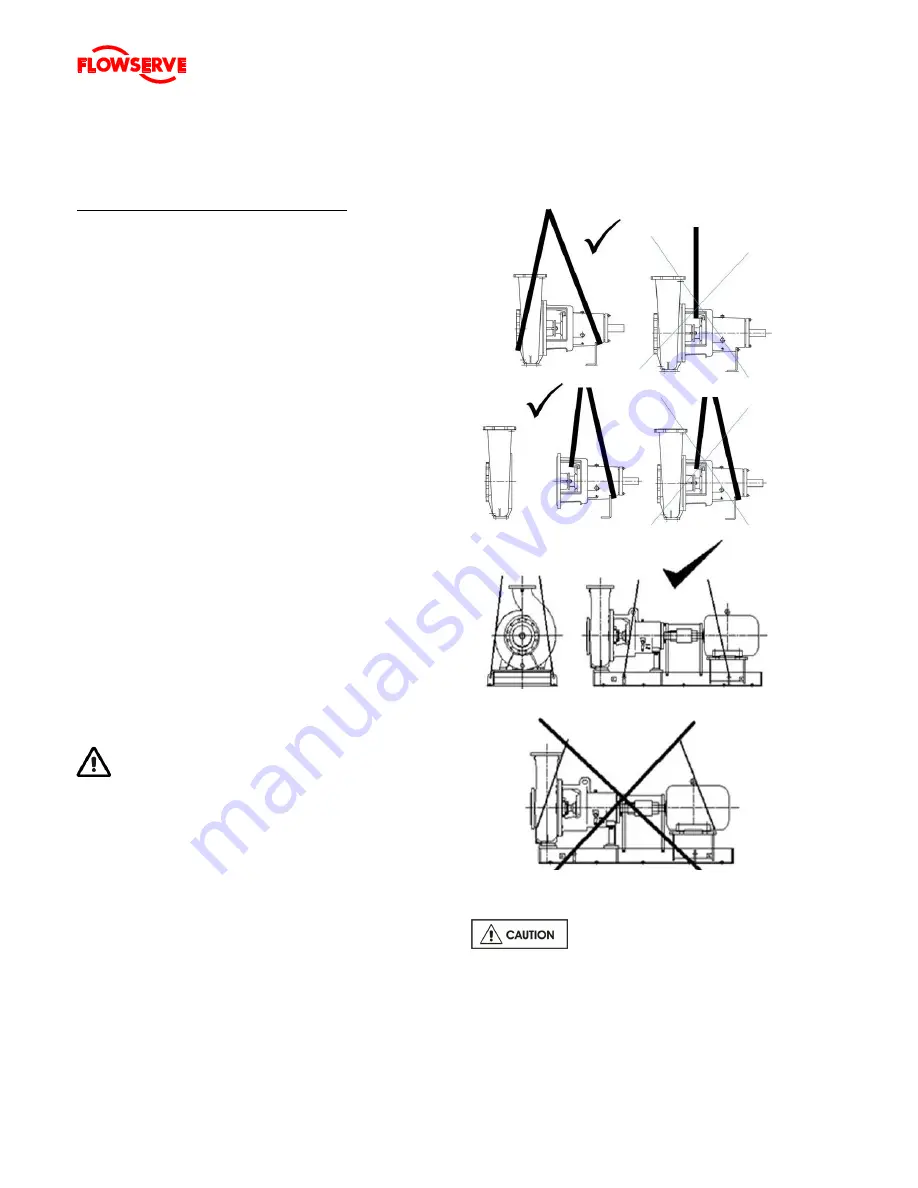

The pump should be lifted with suitably sized and

located slings. Do not use the shaft for lifting and take

special care to prevent the pump from rotating in the

slings due to unbalanced weight distribution.

2.3

Lifting

A crane must be used for all pump sets or

components in excess of 25 kg

(55 lb)

. Fully trained

personnel must carry out lifting, in accordance with

local regulations. The driver and pump weights are

recorded on the general arrangement drawing for the

specific project. The table of engineering data in

section 3.5 is for bare pump only and does not include

the weight of the base, driver or auxiliary equipment.

The pump unit should be lifted as shown. Do not Use

the driver, bare shaft pump or component lifting points

to lift the complete machine.

Before lifting the driver alone, refer to the

manufacturer’s instructions

2.4

Storage

2.4.1

Short

-

Term Storage

When it is necessary to store a pump for a short time

before it can be installed, place it in a dry, cool location.

Protect it thoroughly from moisture and condensation.

Protective flange covers should not be removed until

the pump is being installed.

Wrap the exposed portions of the shaft and coupling to

protect against sand, grit or other foreign matter. Oil