FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 14 of 60

flowserve.com

®

3.4.2

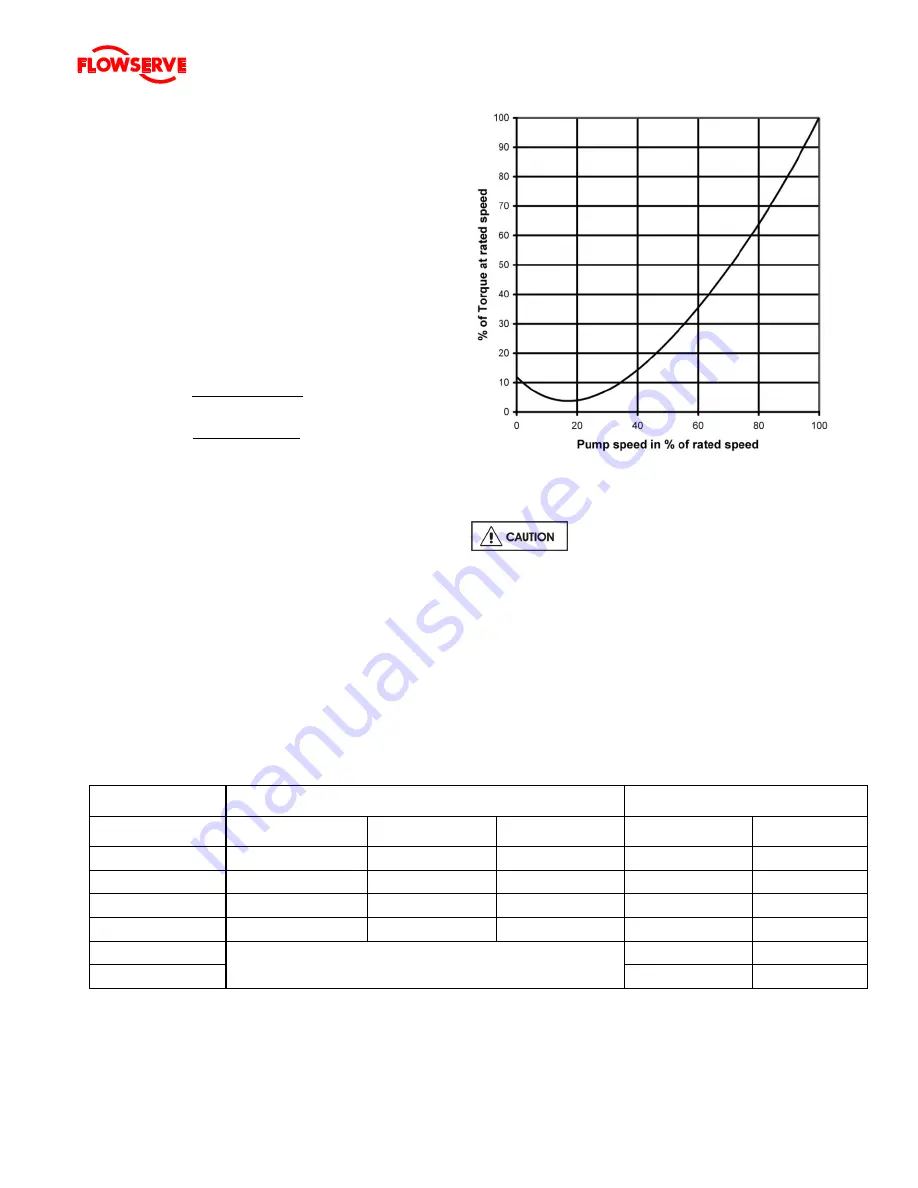

Speed torque curves

To bring a centrifugal pump up to rated speed, the

driver must be capable of providing more torque at

each speed than required by the pump. The margin

between the available and required torque affects the

time it takes the unit to reach full speed. If the torque

required by the pump exceeds the torque capability of

the drive at any run-up speed, the unit will not

accelerate to full speed. Normally, this is not a problem

with standard induction or synchronous motors

provided the proper voltage is supplied at the motor.

For pumps started at shut valve conditions, 100 percent

full speed torque can be calculated by using the

formula:

Torque (N-m) = 9545 Shutoff Power (kW)

r/min

Torque (lbf-ft) = 5250 Shutoff Power (hp)

r/min

Torque required by the pump at any other speed during

start-up can be determined from the curve above. Note

that the driver manufacturer usually bases 100 percent

torque on the design power of the driver and

consequently the speed-torque curves should be

plotted in torque units (e.g. Nm) instead of percentage

torque to avoid confusion.

3.4.3

MAXIMUM WORKING PRESSURES -bar (psi).

Above ambient temperature these maximum pressures

shall be de-rated.

Do no conduct a hydro on the complete

pump set without the specific approval of Flowserve.

While the duty requirement will have been covered,

auxiliary items, flange drillings and suction pressure

limits may impose a reduced static and dynamic

pressure rating compared to that of the pump casting

rating itself.

Note: all flanges are dimensionally compatible with

ANSI 125 (Cast Iron or Ductile Iron-flat faced) or ANSI

150 (Stainless-raised face) unless otherwise stated. All

flange facings on the casings are 250 rms

–

circular

finish (Stock Finish)

CONSTRUCTION

CAST IRON AND C.I.S.S. FITTED

STAINLESS STEEL

316,317L, WORTHITE, ETC.

TEMPERATURE

O

C (

O

F)

UP TO 12”

DISCHARGE

14 TO 16”

DISCHARGE

18 TO 20”

DISCHARGE

UP TO 16”

DISCHARGE

18 TO 20”

DISCHARGE

-30 to 38 (-20 to100)

10.3 (150)

10.3 (150)

6.2 (90)

13.8 (200)

8.3 (120)

65 (150)

10.3 (150)

9.7 (140)

6.2 (90)

13.8 (200)

8.3 (120)

95 (200)

10.3 (150)

9.3 (135)

6.2 (90)

13.4 (195)

8.3 (120)

120 (250)

10.3 (150)

9.0 (130)

6.2 (90)

12.6 (185)

8.3 (120)

150 (300)

Consult factory for applications in this range. Cast

iron not recommended due to thermal shock risks.

12.1 (175)

8.3 (120)

175 (350)

11.0 (160)

7.6 (110)