FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 39 of 60

Flowserve.com

®

6.2.1

Routine inspection (daily/weekly)

The following checks should be made

and the appropriate action taken to remedy any

deviations:

a)

Check operating behaviour. Ensure noise,

vibration and bearing temperatures are normal.

b)

Check that there are no abnormal fluid or lubricant

leaks (static and dynamic seals) and that any

sealant systems (if fitted) are full and operating

normally.

c)

Check that shaft seal leaks are within acceptable

limits.

d)

Check the level and condition of oil lubricant. On

grease lubricated pumps, check running hours

since last recharge of grease or complete grease

change.

e)

Check any auxiliary supplies eg heating/cooling (if

fitted) are functioning correctly.

Refer to the manuals of any associated

equipment for routine checks needed.

6.2.2

Periodic inspection (six monthly)

a)

Check foundation bolts for security

of attachment and corrosion.

b) Check pump running records for hourly usage to

determine if bearing lubricant requires changing.

c)

The coupling should be checked for correct

alignment and worn driving elements.

Refer to the manuals of any associated

equipment for periodic checks needed.

6.2 3

Re-lubrication

Lubricant and bearing temperature analysis can be

useful in optimizing lubricant change intervals. In

general however, the following is recommended.

6.2.3.1 Grease lubrication

See section 5.2.2 for grease

recommendations.

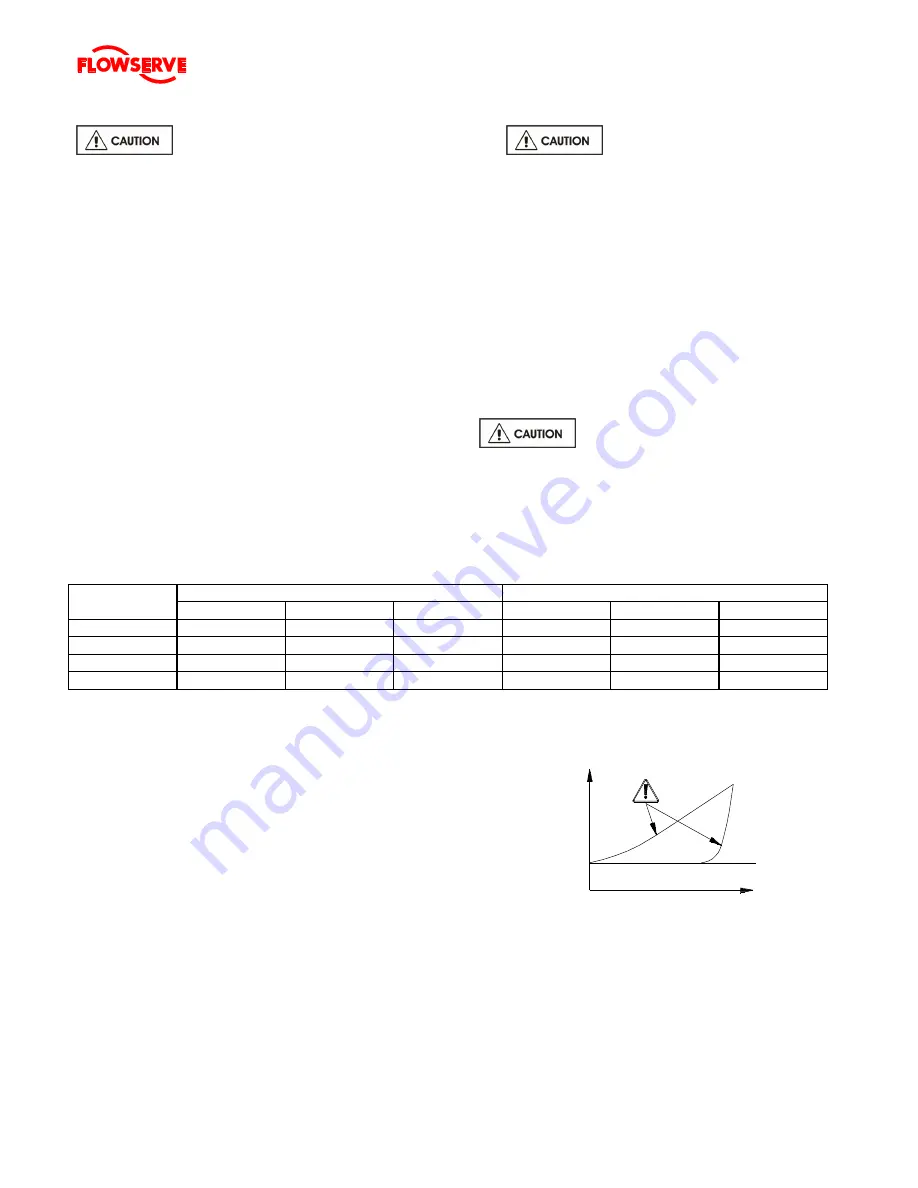

Re-greasing quantities for each bearing are contained in

the table below. Please note that standard pumps are oil

lubricated. Grease only when factory installed grease

fittings are supplied.

Table 6.2.3.1 Bearing Regreasing Quantities

BRG.

THRUST BEARING

LINE BEARING

FRAME SIZE

OZ.

CU. IN.

CU. CM.

OZ.

CU. IN.

CU. CM.

1

1

1.2

20

2

2.4

40

2

3

3.6

60

4

4.9

80

3

7

8.5

140

5

6.1

100

4

9

11.0

180

6

7.3

120

Regrease

- via grease nipples every 2 000 hours or

sooner depending on the severity of the application.

It is important not to under or over grease the bearings

as this will lead to over heating and premature failure.

a) Grease lubricated bearing housings have grease

nipples fitted in the bearing covers.

b) Move the axial seal ring back so the gap between

the pump shaft and bearing cover can be seen.

c) Connect grease gun to the nipple.

d) Press grease into the bearing housing until the

first signs of it appear in the gap between the

housing and shaft, then stop greasing.

e) V-rings should be seated at the proper distance

from the sealing surface to avoid overheating.

f) The maximum allowable operating temperatures

for anti friction bearings will vary from unit to unit,

depending on ambient and fluid temperature. The

rise above ambient should not normally exceed

55

C (131

F) or a combined maximum of 95

C

(204

F).

g) A continuously rising temperature or an abrupt

temperature rise indicates a problem. If these

symptoms occur, stop the pump immediately and

investigate the cause.

TIME

TEMP

ERA

TU

RE

Grease change

- every 4 000 hours or sooner

depending on the severity of the application.

a) Remove the bearing housing from the rotor

assembly.

b) Brush the bearing housing with hot kerosene (100

to 115 °C/212 to 240 °F) or other non-toxic

solvent.