FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 42 of 60

Flowserve.com

®

maintain the impeller axial clearance as detailed in

section 3.5, Table of Engineering Data. Typically

doubling the clearance can reduce performance by

5% depending on pump size and operating condition.

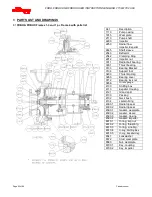

6.8

Disassembly

Refer to section 1.6,

Safety

, before dismantling

the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

To disassemble the pump, consult the sectional

drawings, s

ee section 8,

Parts list and drawings

.

6.8.1

Rotor unit

The following procedure is recommended for removing

and disassembling the back pull-out element (rotating

assembly).

Note that the replacement gaskets and similar

consumable materials should be available since they will

be required for reassembly.

a) Isolate motor and lock off electrical supply in

accordance with local regulations.

b) Isolate suction and discharge valves.

c)

Remove coupling guards and disconnect the

coupling halves.

d)

Drain pump casing. Remove any auxiliary piping

if applicable.

e)

Disconnect stuffing box, cooling water and auxiliary

piping

.

f)

Drain the oil from the bearing bracket [3130] if

bearing frame is being dismantled.

g) Place the sling around the bearing bracket [3130]

and carefully take up the weight without straining the

casing. Refer to Section 3 to determine hoist and

sling requirements.

h) Loosen the set screws holding the deflector [2540]

on the shaft.

i) Release the thrust bearing bracket [3230] hold down

bolts and jam nuts. While rotating the pump shaft

[2110] by hand, tighten the three jacking screws

evenly until the impeller [2200] lightly clamps the

stuffing box head [4100] in place. In the case of

expeller pumps the same will hold for the housing

[4110]. This will simplify withdrawal of the rotating

element from the casing.

Excessive clamping force could

damage bearing races.

Rotating the shaft helps to clear away solids which

may be trapped between the impeller and stuffing

box head.

j) Remove the bolts connecting the rear support foot

[3134] to the baseplate.

k) Remove the frame to casing bolts

l) Withdraw the rotating element from the casing.

For FRBHS designs, there is a loose

adapter [1340] that spaces the bearing bracket [3130]

from the pump casing [1110]. This item may stay lodged

within the casing or could be removed with the rotating

element. Once the rotating element is removed locate

this item and remove it to a safe location.

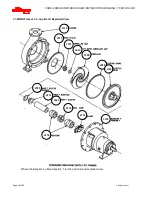

6.8.2

Stuffing box

6.8.2.1

Shaft seal - gland packing

a) Remove gland nuts and gland halves [4121]

b) Lever out gland ring [4130] using its grip groove.

c) Remove gland packing rings [4130] and lantern

rings [4134] using a bent wire.

6.8.2.2

Shaft seal - mechanical seal

Refer to any special instructions supplied with

the mechanical seal.

a)

Remove seal cover screws and pull off seal cover

complete with the stationary seal ring which is held

in place by the O

-

ring seal.

b)

The mechanical seal cover can also be removed by

placing a wedge into the gland chamfer, as below:

6.8.2.3

Impeller and stuffing box

a) While preventing the shaft from rotating, remove the

impeller nut [2912] that has a right hand thread.

b) Remove the impeller [2200] and impeller key [6700].

Normally, a slight tightening of the thrust gearing

jacking screws will free the impeller and allow it to be

removed. Except on the smaller sizes, there is a

facility on the impeller hub to assist removal in

difficult cases.

c) Remove the expeller housing [4110] & radial impeller

[2250] and/or stuffing box head [4100] as applicable

to pump construction.

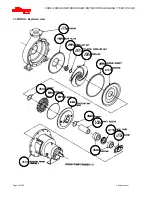

6.8.3

Shaft sleeve

a) Remove the shaft sleeve gasket [4590].

b) Remove the shaft sleeve [2445] if scored or worn.

6.8.4

Bearing housing

a) Remove the deflector [2540] and the line bearing

cover.

b) Remove the pump half coupling and coupling key

[6700].

c) Remove the support foot [3134].

d) Lift the bearing frame assembly into a vertical

position with the thrust bearing housing [3230] up.

Rest the bearing frame flange on heavy wooden

blocks sufficiently high to ensure end of the shaft

does not come into contact with the floor or table.

e) Remove the thrust bearing hold down bolts and