FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 43 of 60

Flowserve.com

®

remove shaft assembly for the bearing bracket

[3130].

6.8.5

Line bearing

a) Lay the pump shaft [2110] horizontal and support

with wooden ‘V’ Blocks.

b) Only if necessary remove the radial ball bearing

[3011] from the shaft. Bearings removed and reused

can easily be damaged and undetected until pump is

put back in operation,

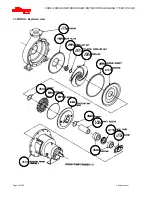

6.8.6

Thrust bearings

a) Lay the pump shaft [2110] horizontal and support

with wooden ‘V’ Blocks.

b) Remove the thrust bearing clamping ring [2542] from

the thrust bearing bracket [3230].

c) Bend up the locking tab on the bearing nut

lockwasher [6541] and remove the bearing lock-nut

[3712] and lockwasher [6541].

d)

Only if necessary remove the thrust bearings [3031]

from the shaft. Bearings removed and reused can

easily be damaged and undetected until pump is put

back in operation

6.8.7 Wearplate

a) The wearplate can be removed from the casing if

required. The wearplate is secured in place using

studs and hex nuts.

6.9 Examination of parts

Used parts must be inspected before

assembly to ensure the pump will subsequently run

properly.

In particular, fault diagnosis is essential to enhance

pump and plant reliability.

6.9.1 Casing, seal housing and impeller

a) Inspect for excessive wear, pitting, corrosion,

erosion or damage and any sealing surface

irregularities.

b)

Replace as necessary.

c) Inspect the impeller [2200] and the wearplate [1915]

for excessive wear or damage. Remove the

wearplate from the pump casing [1110] if necessary.

d) Inspect the pump casing [1110] and stuffing box

head [4100] for damage or excessive thinning of wall

sections due to wear or corrosion. Clean the internal

surfaces to maintain pump efficiency.

e) Inspect the stuffing box neck bush [4132] and

remove if damaged or worn. Clean the internal bore

of the stuffing box.

6.9.2 Shaft and sleeve (if fitted)

a) Replace sleeve if grooved, pitted or worn.

b)

Clean the shaft and inspect for evidence of

corrosion, evidence of cracking, fatigue or

mechanical damage. Remove all burrs or nicks

paying particular attention to the areas under the

lip seals. Check that the shaft is straight within

0.002 inch (0.050 mm).

6.9.3

Gaskets and O

-

rings

After dismantling, discard and replace.

6.9.4

Bearings

a) It is recommended that bearings are not re-used

after any removal from the shaft.

b)

The plain liquid lubricated bearings may be re

-

used if both the bearing bush and bearing sleeve

show no sign of wear, grooving or corrosion

attack. (It is recommended that both the bush and

sleeve are replaced at the same time.)

6.9.5

Bearing isolators, labyrinths or lip seals

(if fitted)

a) The lubricant, bearings and bearing housing seals

are to be inspected for contamination and

damage. If oil bath lubrication is utilised, these

provide useful information on operating conditions

within the bearing housing.

b)

If bearing damage is not due to normal wear and

the lubricant contains adverse contaminants, the

cause should be corrected before the pump is

returned to service.

c)

Labyrinth seals and bearing isolators should be

inspected for damage but are normally non

-

wearing parts and can be re

-

used.

d)

Bearing seals are not totally leak free devices.

Oil from these may cause staining adjacent to the

bearings.

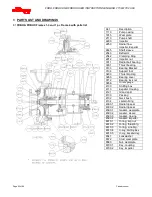

6.10

Assembly

To assemble the pump consult the sectional drawings,

s

ee section 8,

Parts list and drawings

.

Ensure threads, gasket and O-ring mating faces are

clean. Apply thread sealant to non-face sealing pipe

thread fittings.

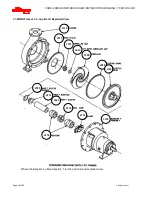

6.10.1

Bearing housing

a) Lubricate the internal bores of the bearing bracket

[3130] with the same oil or grease used to lubricate

the bearings.

b) Install the thrust bearing housing [3230] in the

bearing bracket [3130] to ensure a good sliding fit.

Remove the thrust bearing housing from the frame.

c) Install the oil sight gauge [3856] and the drain lug in

the bearing bracket [3130] using Teflon pipe thread

sealant. Install the threaded plug (vent plug) [6578].