FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 44 of 60

Flowserve.com

®

6.10.2

Line bearing

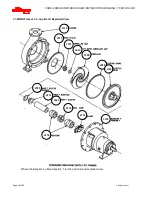

a) Pack the line bearing with grease if the bearings are

being grease lubricated.

b) Lightly lubricate the pump shaft [2110] at the line

bearing position. Install the radial ball bearing [3011]

on the shaft. Use an induction heated or hot oil bath

to first heat the bearing [250

F recommended],

press the bearing on shaft with the aid of a sleeve

designed to push the inner race only. Note that the

bearing must remain square to the shaft during

assembly and that the inner race must seat on the

shaft shoulder. Protect the bearing by wrapping with

a clean, lint free cloth.

6.10.3

Thrust bearing

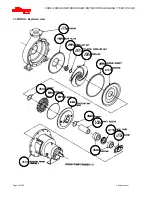

a) Pack thrust bearing with grease if the bearings are

being grease lubricated.

b) Place the thrust bearing clamping ring [2542] loosely

over the shaft on the largest diameter.

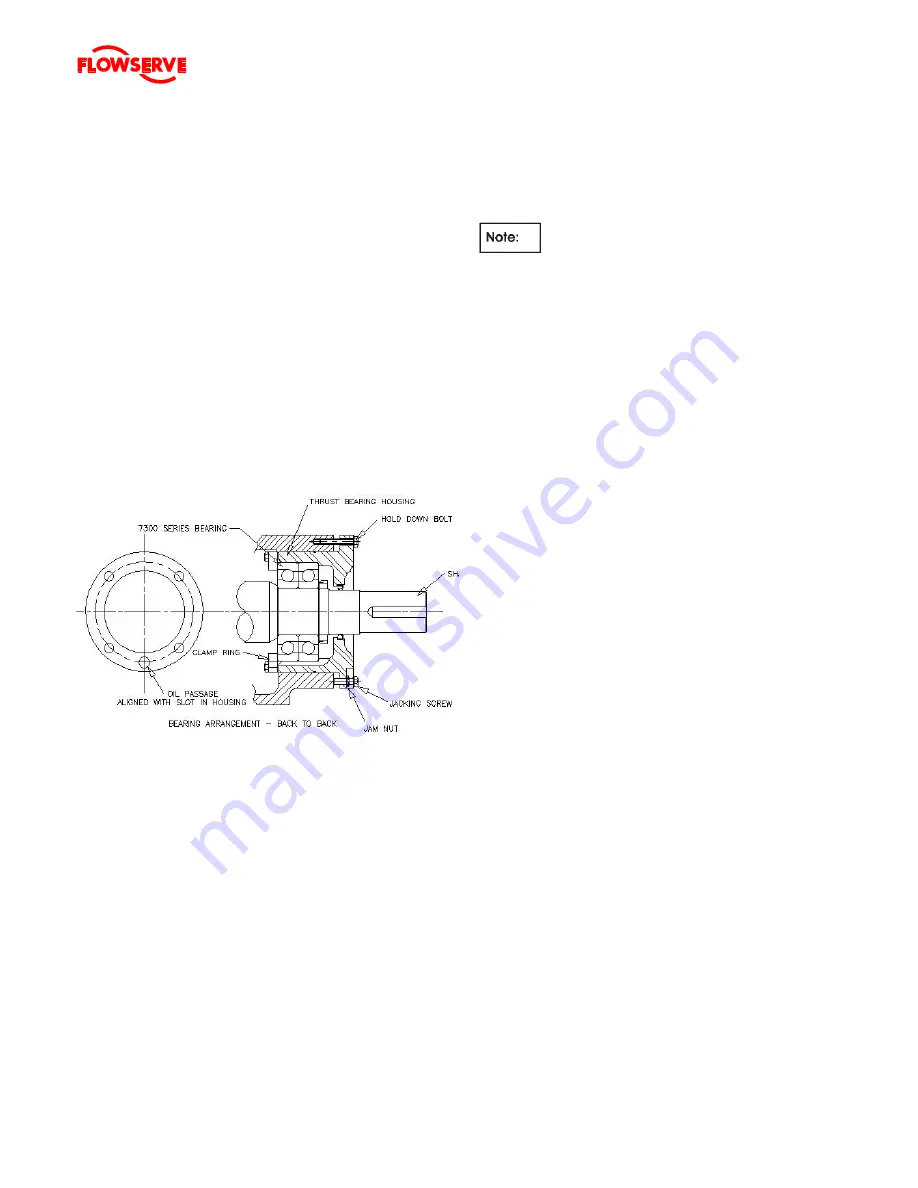

c) Install the angular contact bearings [3031] on the

pump shaft [2110] using the same procedure as

described in step 6.10.2. The bearings are mounted

back to back as shown.

d) Slide the bearing lockwashers [6541] on the shaft

and fit the bearing lock nut [3712]. Tighten the

locknut snugly and allow to cool. Check the

tightness and bend one tab on the lockwasher into a

slot in the locknut. Protect the bearings from

contamination.

e) Carefully install the lip seal [4300.1] in the thrust

bearing housing [3230] by pressing it squarely into

the bore. The primary sealing lip [spring loaded] on

seal should be installed facing the bearing. A small

amount of sealant may be applied on the O.D. of the

seal prior to its' installation.

f) Install the square head plug or grease fitting on the

tapped hole in the thrust bearing housing flange.

Lubricate the O-ring [4610.4] with the bearing

lubricant and assemble it into the groove of the outer

circumference of the thrust bearing housing [3230].

g) Lubricate the inside bore of the thrust bearing

housing [3230] and assemble it over the thrust

bearings. Care must be taken to prevent damage of

the seal on the shaft.

h) Using capscrews and lockwashers, attach the thrust

bearing clamping ring [2542] to the thrust bearing

housing [3230]. Lock the threads using Loctite 242

or equivalent.

The thrust bearing clamping ring [2542] is

provided with one extra hole midway between two

adjacent bolt holes to permit free oil flow. On oil

lubricated units, this hole must align with the cast oil

return at the bottom of the thrust bearing housing bore.

For grease lubricated units, this hole should be oriented

away from the cast oil return slot at the bottom the thrust

bearing housing bore.

Tighten the capscrews evenly ensuring that the clamp

ring is not distorted and gap to the bearing housing is

even all around. Tighten in accordance with Table 6.6.

6.10.4

Frame assembly

6.10.4.1

Frame 1, 2 & 3

a) Place the bearing frame in a vertical position with the

large flange resting on wooden support blocks

sufficiently high to allow the shaft from contacting the

floor when it is installed.

b) Lift the shaft assembly into a vertical position and

lower it into the bearing bracket [3130]. Note the

square head plug (or grease fitting in the thrust

bearing housing [3230] must align with the threaded

plug [6578] in the bearing bracket [3130].

6.10.4.2

Frame 4 for 18FRBH274 & 20FRBH304

only

a) Assemble the adapter [1340] to the bearing bracket

[3130].

6.10.4.3

Frame 4 only

a) Place the shaft assembly in a vertical position with

the thrust bearing housing [3230] resting on the

flange face and supported by blocks or clamps.

Access to one through hole in the thrust bearing

housing is required to attach one bolt.

b) Lift the bearing bracket assembly [3130] vertically and

lower over the shaft assembly. Manually guide the line

bearing outer race into the bearing frame bore. Ensure

that the thrust bearing housing [3230] and frame [3130]

are oriented as in Step 6.10.4.1 b). This will ensure that

the oil return slot in the thrust bearing housing [3230] is

properly located.

6.10.4.4

All frames

a) Install at least one thrust bearing housing to bearing

frame hold down capscrews complete with

lockwasher to prevent the assembly from coming

apart when lifting.

b) Place the bearing frame assembly into a horizontal

position.