FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 46 of 60

Flowserve.com

®

For units with mechanical seals, do not

apply thread locking compound until seal axial

setting has been established.

d) Tighten the impeller nut [2912] in accordance with

Table 6.6. This is an essential step to properly seat

the shaft sleeve [2445] and compress the gasket

[4590.2] to provide a seal and to prevent loosening

of the impeller on the shaft.

e) Release the thrust bearing housing hold down bolts

and tighten the jacking screws to pull the impeller

back to the stuffing box head [4100]. The stuffing

box head must not be rigidly clamped.

6.10.7

Wearplate

a) Install the studs [6572] in the wearplate [1915] using

Loctite grade A or equivalent. Place the sealing

washer [4590.1] over the studs [6572] and install the

wearplate into the pump casing [1110]. Secure

wearplate [1915] in place using hex nuts and

washers using Loctite 242 or equivalent. Tighten in

accordance with Table tables in section 6.6.

Excessive or uneven tightening torque may distort wearplate

affecting impeller running clearances or result in broken

studs.

b) Stand the casing on it's feet.

c) Smear a small amount of grease or anti-seize

compound over one face of the gasket [4590.3] and

place it on the stuffing box head [4100] with coated

face against flange.

Some sizes, as identified in Section I use an o-

ring in place of a gasket.

6.10.8 FRBHS only

a) Take spacer and install gasket [4590.3] with a small

amount of grease on the face that will mate inside

the pump casing [1110].

b) Smear anti-seize compound on the pump casing

[1110] and adapter [1340] rabbit fit (spigot)

diameters to ease assembly and future disassembly.

c) Install the adapter/gasket [1340/4590.3] into the

pump casing [1110].

This piece is loose so caution must be

exercised when moving around the casing.

6.10.9

All pumps except FRBHS

a)

Smear anti-seize compound on the pump casing

[1110] and stuffing box head [4100] rabbit fit (spigot)

diameters to ease assembly and future disassembly.

6.10.10

Rotor unit

a) With a sling around the bearing frame placed so as

to balance the weight, lift the frame/impeller

assembly keeping the shaft horizontal.

b) Install the frame/impeller assembly into the pump

casing [1110] by guiding the stuffing box head and

bearing frame spigots squarely into the casing

recess. Ensure that the gasket [4590.3] stays in

position. If the fit becomes snug, use 4 equally

spaced bolts to draw the assembly into the casing.

c) Install the casing frame bolts with washers and

tighten in accordance with Table 6.6.

d) Using the thrust bearing housing adjustment feature

[Figure 8], move the impeller forward away from the

stuffing box head [4100].

e) Attach the bearing frame support foot [3134] to the

bearing bracket [3130] using the capscrews and

washers. Ensure that thread engagement is atleast 1

diameter. Use Loctite 242 thread sealant.

lockwashers should not be used to ensure

proper thread engagement with standard bolting.

f) Set the impeller front clearance in accordance with

instruction earlier in this section of the manual.

6.10.11

Shaft seal

6.10.11.1

Packing

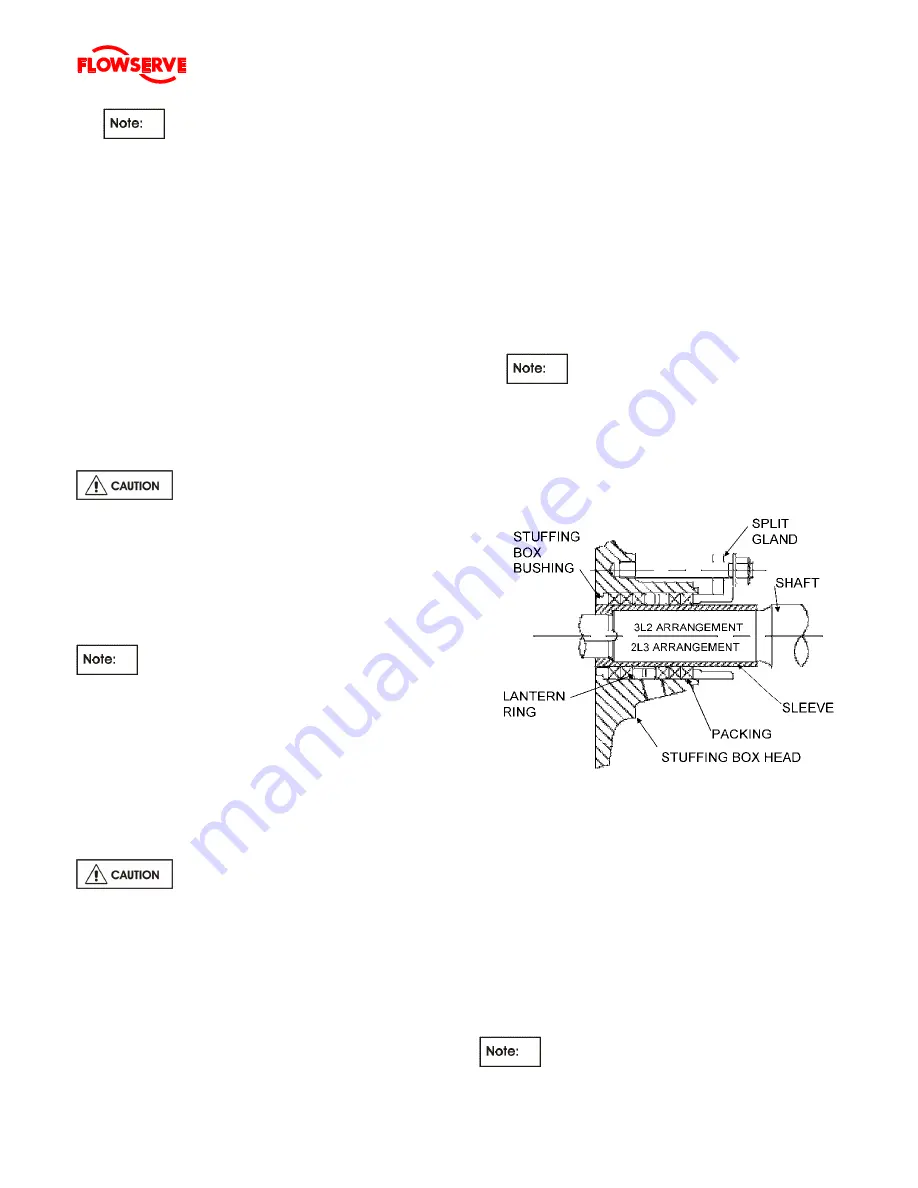

Standard Packed Box Arrangement

a)

Insert one packing ring at a time into the stuffing box.

Push the packing as far as possible into the packing

bore.

b)

Install additional rings as required, staggering the

joints.

c)

Once the first two or three rings of packing have

been inserted, the two piece lantern ring [4134] must

be installed. Push the lantern ring and previously

installed packing. The ports in the lantern ring do not

need to be aligned with the inlet/outlet ports.

d)

Ensure that the shaft can be turned by hand.

e)

Install the remaining rings of packing, alternating the

joints.

It may not be possible to insert the last ring in