FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 41 of 60

Flowserve.com

®

6.3

Spare parts

6.3.1

Ordering of spares

Flowserve keep records of all pumps that have been

supplied. When ordering spares the following

information should be quoted:

1)

Pump serial number

2)

Pump size

3)

Part name – taken from section 8

4)

Part number – taken from section 8

5)

Number of parts required

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non

-

standard part) will

invalidate the pump’s safety certification.

6.3.2

Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re

-

treatment of metallic

surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

6.4

Recommended spares and consumable items

For start up purposes:

1

-

complete set of gland packing

2

-

shaft sleeves

1

-

set of gaskets and seals

(optional: 2

-

mechanical seals)

For 2 years operation:

1

-

set of bearings (line and thrust)

2

-

sets of gland packing

2

-

shaft sleeves

2

-

sets of gaskets and seals

2

-

lantern rings

2

-

casing wear rings

(optional: 2

-

mechanical seals

2

-

impeller wear rings)

For 4 years operation:

1

-

set of bearings (line and thrust)

2

-

sets of gland packing

2

-

shaft sleeves

2

-

sets of gaskets and seals

2

-

lantern rings

2

-

casing wear rings

1

-

impeller

(optional: 2

-

mechanical seals

1

-

wearplate)

6.5

Tools required

A typical range of tools that will be required to

maintain these pumps is listed below.

Readily available in standard tool kits, and dependent

on pump size:

•

Open ended spanners (wrenches) to suit up to

M 48 screws/nuts

•

Socket spanners (wrenches), up to M48 screws

•

Allen keys, up to 10 mm (A/F)

•

Range of screwdrivers

•

Soft mallet

More specialized equipment:

•

Bearing pullers

•

Bearing induction heater

•

Dial test indicator

•

C-spanner (wrench) - for removing shaft nut.

(If difficulties in sourcing are encountered, consult

Flowserve.)

6.6

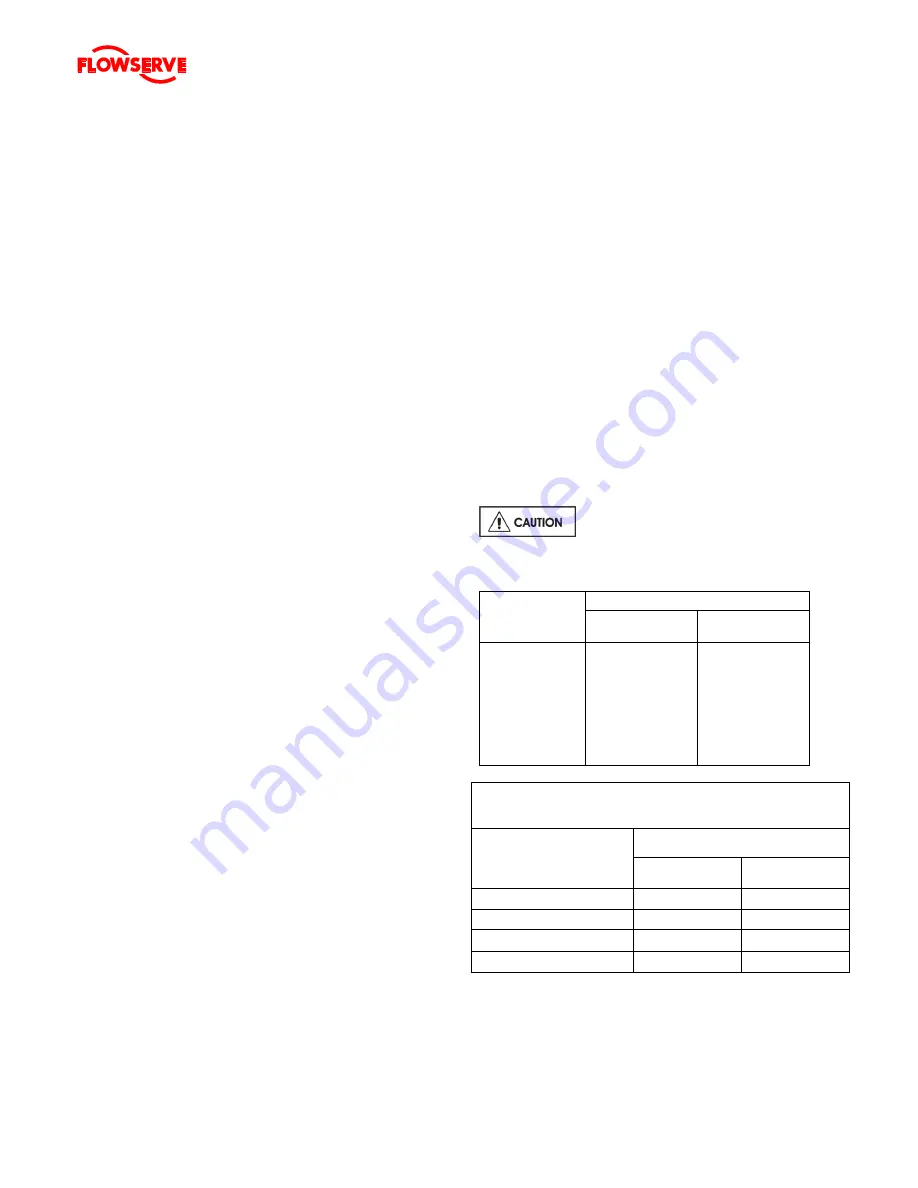

Fastener torques

Non-metallic gaskets incur creep

relaxation

–

retighten to the tightening torques

provided.

Bolt size

Torque Nm (lb

ft)

Pump feet

fasteners

All other

fasteners

M 16 (⅝ in.)

M 20 (¾ in.)

M 24 (⅞ in.)

M 27 (1 in.)

M 30 (1⅛ in.)

M 36

(1⅜ in.)

M 42 (1⅝ in.)

M 48 (1⅞ in.)

170 (125)

340 (250)

590 (435)

770 (570)

1 100 (810)

1 840 (1 350)

2 000 (1 475)

2 240 (1 650)

84 (62)

165 (120)

285 (210)

375 (275)

540 (400)

900 (660)

1 410 (1 040)

2 060 (1 500)

TIGHTENING TORQUE FOR STAINLESS STEEL STUDS

WITH LUBRICATED THREADS

THREAD SIZE

TIGHTENING TORQUE

Nm.

Ft. lbs.

M10x1.5 (3/8

–

16UNC)

13

10

M12x1.75 (1/2

–

13UNC)

27

20

M16X2 (5/8-11UNC)

60

45

M20x2.5 (¾-10UNC)

100

75

6.7

Renewal clearances

As wear takes place between the impeller and

wearplate the overall efficiency of the pump set will

decrease. To maintain optimum efficiency, it is

recommended that the impeller be adjusted to