HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 30 of 60

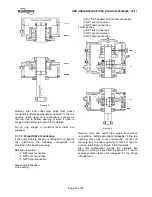

Bearing Designation

Oil Fill Capacity

D.E. Side

N.D.E. Side

Bearing

Housing

Size (*)

Radial

Bearing

Bore [mm]

Thrust Bearing

litres (oz)

litres (oz)

ESB 0

40

2 x 7308 BG

0.80 (27.1)

1.50 (50.7)

ESB 1

50

2 x 7308 BG

0.80 (27.1)

1.50 (50.7)

ESB 2

60

2 x 7312 BG

1.50 (50.7)

2.75 (93.0)

ESB 34

70

2 x 7312 BG

1.50 (50.7)

2.75 (93.0)

ESB 5

80

2 x 7312 BG

1.50 (50.7)

2.75 (93.0)

ESB 6

90

2 x 7312 BG

1.50 (50.7)

2.75 (93.0)

ESB 7

100

2 x 7317 BG

3.00 (101.4)

7.00 (236.7)

ESB 8

120

2 x 7317 BG

3.00 (101.4)

7.00 (236.7)

ESB 9

140

2 x 7222 BG

5.50 (186.0)

9.00 (304.3)

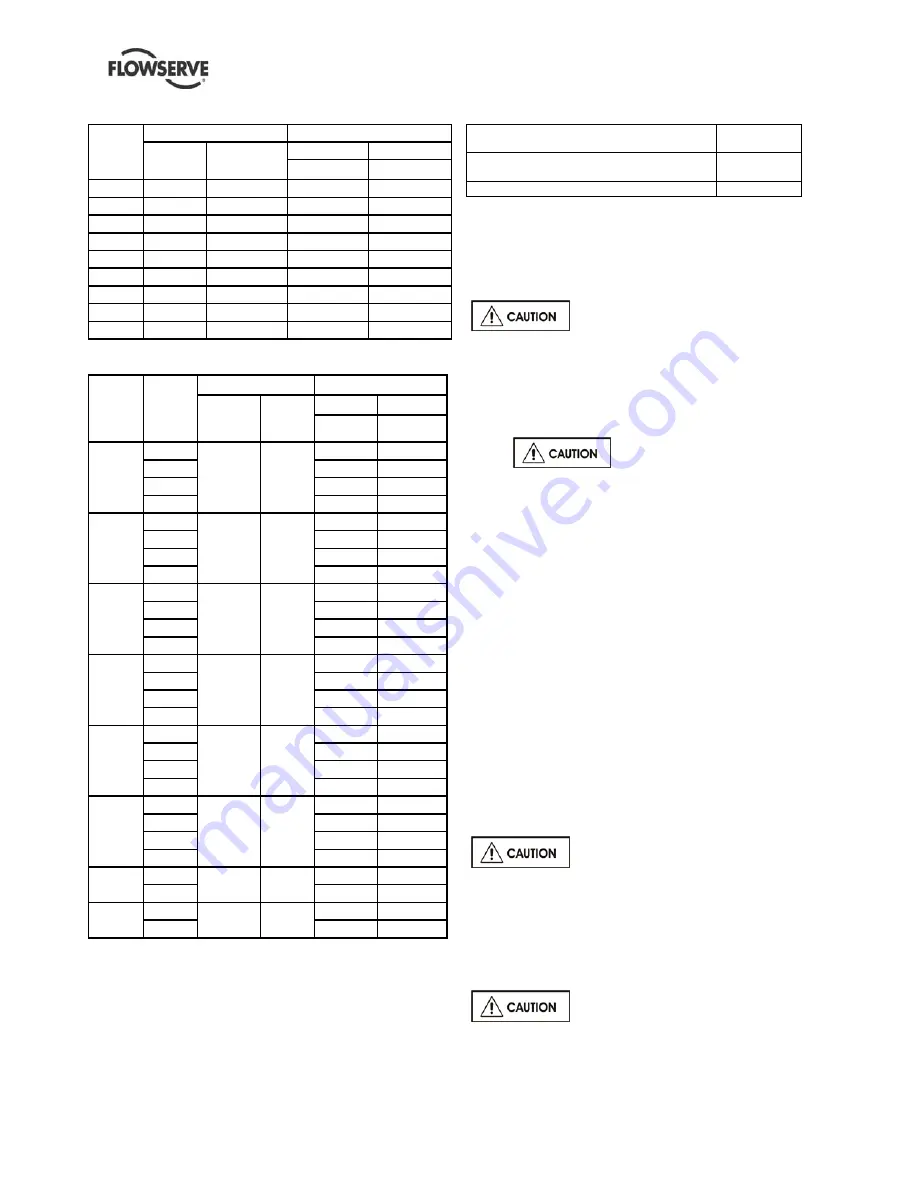

5.2.2.3 KTB

Bearing Designation

Oil Capacity

D.E. Side

N.D.E. Side

Bearing

Housing

Size (*)

Rated

Speed

r.p.m.

Radial

Bearing

Bore mm

Thrust

Bearing

l/min

(gall/min)

l/min

(gall/min)

1500

0.9 (0.2)

1.9 (0.5)

1800

1.0 (0.3)

3.0 (0.8)

3000

1.4 (0.4)

5.2 (1.4)

EK 1

3600

50 4

1.8 (0.5)

6.2 (1.6)

1500

1.0 (0.3)

4.2 (1.1)

1800

1.1 (0.3)

5.1 (1.4)

3000

1.6 (0.4)

9.4 (2.5)

EK 2

3600

60 5

2.1 (0.6)

11.1 (2.9)

1500

1.2 (0.3)

4.4 (1.2)

1800

1.4 (0.4)

5.4 (1.4)

3000

2.0 (0.5)

9.8 (2.6)

EK 34

3600

70 5

2.5 (0.7)

11.5 (3.0)

1500

1.4 (0.4)

4.6 (1.2)

1800

1.7 (0.4)

5.7 (1.5)

3000

2.4 (0.6)

10.2 (2.7)

EK 5

3600

80 5

2.9 (0.8)

11.9 (3.1)

1500

1.7 (0.5)

4.9 (1.3)

1800

2.0 (0.5)

6.0 (1.6)

3000

2.8 (0.7)

10.6 (2.8)

EK 6

3600

90 5

3.4 (0.9)

12.4 (3.3)

1500

2.0 (0.5)

5.2 (1.4)

1800

2.4 (0.6)

6.4 (1.7)

3000

3.3 (0.9)

11.1 (2.9)

EK 7

3600

100 5

3.8 (1.0)

12.8 (3.4)

1500

2.6 (0.7)

10.6 (2.8)

EK 8

1800

120 7

3.1 (0.8)

14.7 (3.9)

1500

3.5 (0.9)

22.5 (5.9)

EK 9

1800

140 9

4.0 (1.1)

32.0 (8.5)

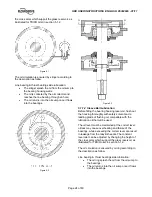

* The bearing housing size can be identified from the

identifying marks cast on the housing on the

horizontal centre line in the opposite side to the oiler

and from the thrust bearing side indicated by

nameplate.

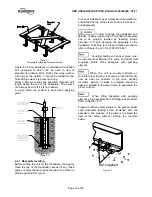

5.2.3 Bearing housing oil limitations

Recommended Oil Temperature At Start Up

15.6 °C

60 °F

Desirable Operating Temperature

60-71 °C

140-160 °F

Oil Level Above Oil Connection Centre line

6 mm

When the starting temperature is below -10 °C

(14 °F) for long time it’s suggested to use a synthetic

oil. Other drivers and gearboxes, if appropriate,

should be lubricated in accordance with their

manuals.

In the case of product lubricated bearings

the source of product supply should

be checked against

the order. There may be requirements for an external

clean supply, particular supply pressure or the

commencement of lubrication supply before pump

start-up.

5.2.4

Lubrication schedule

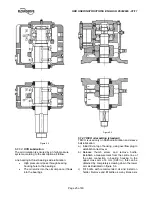

5.2.4.1 Oil lubricated bearings

Normal oil change intervals are 4000 operating hours

or at least every 6 months. For pumps on hot service

or in severely damp or corrosive atmosphere, the oil

will require changing more frequently. Lubricant and

bearing temperature analysis can be useful in

optimizing lubricant change intervals.

The lubricating oil should be a high quality mineral oil

having foam inhibitors. Synthetic oils may also be

used if checks show that the rubber oil seals will not be

adversely affected.

Based on the specified operating conditions and an

ambient temperature of 43°C (110°F) for ring-oiled or

splash systems, oil sump temperature below 82 C

(180°F) is expected.

A continuously rising temperature, or an abrupt rise,

indicates a fault.

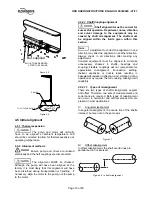

5.3 Direction of rotation

Ensure the pump is given the same

rotation as the pump direction arrow fit on bearing

housing. In any case the direction of rotation must be

checked with the pump disconnected.

To avoid dry running the pump must either be filled

with liquid or have the flexible coupling disconnected

before driver is switched on.

If maintenance work has been carried

out to the site's electricity supply, the direction of

rotation should be re-checked as above in case the

supply phasing has been altered.