HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 37 of 60

i) It is advisable to thoroughly drain and dry off the

base plate before attempting any maintenance

work on the pump.

This could eliminate the risk of slipping on a

wet surface causing personal injury or mechanical

damage.

j) Remove pump monitoring equipment, auxiliary

services or any other plant or equipment that may

interfere with safe dismantling of the pump.

k) Loosen set screw securing coupling nut and

remove nut.

l) Remove pump coupling hub, using a puller.

Remove coupling key.

m) When cartridge type mechanical seals are used,

loosen seal drive collar set screws. Insert first

locking tab into seal sleeve groove. Consult

mechanical seal manufacturer’s instructions.

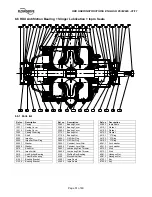

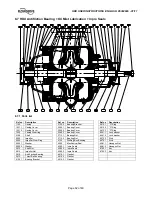

n) Proceed now with the dismantling of the pump

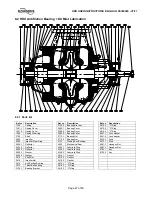

following the steps listed below. For location of

parts refer to pump sectional drawing and part

list.

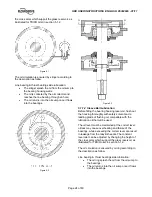

6.7.2 Thrust Bearing Disassembly

6.7.2.1 Ball Ball

a) Remove outer bearing cover.

b) Release locking tab of thrust bearing lock-

washer.

c) Loosen and remove bearing lock nut and lock-

washer.

d) Remove spacer together with slinger.

e) Unbolt screws fixing the inner cover.

f) Pull out thrust bearing housing.

g) Fit a bearing puller on the inner shield and pull

out thrust bearing assembly together with inner

bearing cover and shield.

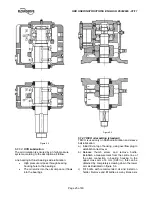

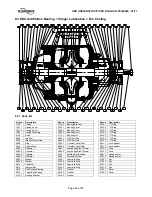

6.7.2.2 Sleeve Ball

a) Remove fan guard and fan, if any.

b) Remove bolting securing end cover to bearing

housing and remove cover.

c) Remove all bolting and taper pins holding upper

half of thrust bearing housing and remove it. Use

jack bolts and eyebolts for removal.

d) Unbolt calibrated screws and remove top half

sleeve bearing.

e) Slide oil rings onto shaft apart from lower half

sleeve bearing.

f) Carefully lift pump shaft just enough so that lower

half sleeve bearing can be removed.

g) Unbolt and remove lower half of thrust bearing

housing.

h) Release locking tab of thrust bearing lock-

washer. Loosen and remove thrust bearing lock

nut and lock-washer.

i) Remove thrust bearing assembly, using a puller

that will bring pressure against inner bearing race

only.

j) Remove oil rings. Unscrew set screws and

remove inboard oil shield together with labyrinth

ring.

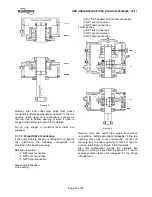

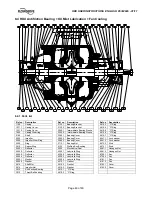

6.7.2.3 KTB

a) Remove bolting securing end cover to bearing

housing and remove cover along with outboard

shim.

b) Remove all bolting and taper pins holding upper

half of thrust bearing housing and remove it. Use

jack bolts and eyebolts for removal.

c) Remove top half sleeve bearing.

d) Remove thrust shoes, leveling plates and split

base rings. Consult Kingsbury’s instructions.

e) Unscrew set screws and remove thrust collar

locking nut.

f) Remove thrust collar and key. Remove inboard

shim and oil seal in two halves.

g) Carefully lift pump shaft just enough so that lower

half sleeve bearing can be removed.

h) Unbolt and remove lower half of thrust bearing

housing.

i) Remove inboard labyrinth ring. Unscrew set

screws and remove inboard oil shield.

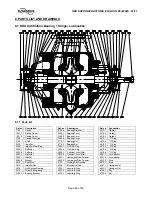

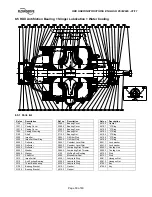

6.7.3

Line Bearing Disassembly

6.7.3.1 Ball Ball

a) Unscrew grub screws and remove outer shield.

b) Unbolt outer bearing cover.

c) Release locking tab of line bearing lock- washer.

d) Loosen and remove bearing lock nut and lock-

washer.

e) Remove spacer together with oil ring.

f) Unbolt inner cover fixing screws.

g) Pull out line bearing housing.

h) Fit a bearing puller on the inner shield and pull

out line bearing, inner bearing cover and shield

contemporary.

6.7.3.2 Sleeve Ball

a) Remove fan guard and fan, if any.

b) Remove all bolting and taper pins holding upper

half of line bearing housing and remove it. Use

jack bolts and eyebolts for removal.

c) Unbolt calibrated screws and remove top half

sleeve bearing.

d) Slide oil rings onto shaft apart from lower half

sleeve bearing