HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 39 of 60

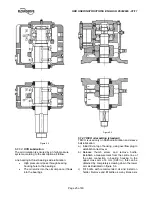

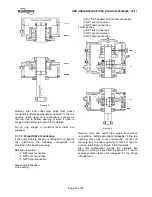

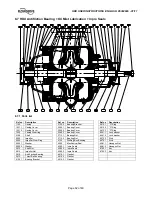

PUMP TYPE HDX

U

U

MINIMUM DIAMETER CLEARANCES

Minimum Diameter Clearance

Minimum Diameter Clearance

Temp. up to 260°C

(500°F)

Temp. above 260°C

(500°F)

Wear ring

Wear ring

Wear ring.

Nominal diameter

CastIron /Bronze

12% Chr.Steel

316 Stn. Steel

Carbon-Steel

CastIron/Bronze

12% Chr.Steel

316 Stn. Steel

Carbon-Steel

mm (in.)

mm mm mm mm

Up

To

50.8 (2.0)

0.26

0.39

0.39

0.51

50.9 (2.0)

÷

63.4 (2.5)

0.28

0.41

0.41

0.53

63.5 (2.5)

÷

76.1 (3.0)

0.30

0.43

0.43

0.55

76.2 (3.0)

÷

88.8 (3.5)

0.36

0.49

0.49

0.61

88.9 (3.5)

÷

126.9 (5)

0.40

0.53

0.53

0.65

127 (5.0)

÷

152.3 (6.0)

0.43

0.56

0.56

0.68

152.4 (6.0)

÷

177.7 (7.0)

0.46

0.59

0.59

0.71

177.8 (7.0)

÷

203.1 (8.0)

0.48

0.60

0.60

0.73

203.2 (8.0)

÷

228.5 (9.0)

0.50

0.63

0.63

0.75

228.6 (9.0)

÷

253.9 (10.0)

0.53

0.66

0.66

0.78

254 (10.0)

÷

279.3 (11.0)

0.56

0.69

0.69

0.81

279.4 (11.0)

÷

304.7 (12.0)

0.59

0.72

0.72

0.84

304.8 (12.0)

÷

330.1 (13.0)

0.61

0.74

0.74

0.86

330.2 (13.0)

÷

355.5 (14.0)

0.64

0.77

0.77

0.89

355.6 (14.0)

÷

380.9 (15.0)

0.66

0.79

0.79

0.91

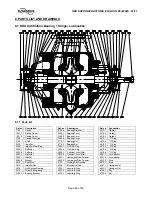

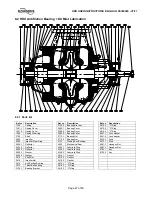

6.8.2 Impeller

a) Remove worn impeller rings by mechanical

turning.

b) Slightly eroded parts can be repaired by welding.

Dynamically balance impellers after any machine

work. To balance remove metal from the front or

back shroud of the impeller at the point of

unbalance

6.8.3 Mechanical seal

a) Mechanical seal stationary and rotating faces

should be inspected for signs of wear or cracks

and replaced as necessary.

b) It is recommended that when reassembling

mechanical seal new "O" rings and gaskets be

used.

c) Refer to manufacturers drawing for assembly of

mechanical seal. Refer to mechanical seal

section within this manual for further details.

6.8.4 Stuffing Box Bushings (If fitted)

a) Check the stuffing box bushes and replace if

cocked and /or worn.

b) To replace, chill the new bushings to -20°C and

install in the stuffing boxes

6.8.5 Shaft

When the pump is dismantled, examine the shaft

carefully. Its condition should be checked at the

impeller hub fit, deflectors and at the bearings. The

shaft may become damaged by rusting or pitting

because of leakage along the shaft at the impeller or

shaft sleeve. Anti-friction bearing improperly fitted to

the pump shaft will cause the inner race to rotate on

the shaft.

Check the shaft keyway for distortion.

Excessive thermal stresses or corrosion may loosen

the impeller on the shaft and subject the keyway to

excessive shock. Replace a shaft that is bent or

distorted. Check a shaft that has been repaired for

possible runout (maximum 0.050 mm).

The shaft sleeve is subject to wear and may require

replacement, depending on the severity of service

Replace if grooved, pitted or worn.

6.8.6 Gaskets and O-rings

After dismantling, discard and replace.

6.8.7 Bearings

6.8.7.1 Ball Ball

a) It is recommended that bearings are not re-used

after any removal from the shaft. In any case the

bearings must be replaced not after 25000

operating hours.

b) If the bearing cannot be removed with the tools

available never use a torch under any