HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 40 of 60

circumstances. Split the outer ring with a small

hand grinder, saw through the ball/roller retainer,

and split the inner ring about three quarters

through with a grinder and break with a cold steel

chisel.

Do not attempt to inspect condition

of bearings until they have been cleaned.

c) Solvent for cleaning bearings should be in a

clean container. Place bearings in solvent and let

soak for a short time. Agitate the bearing around

near the top of the container, giving it a turn now

and then until it is clean. Rinse in a clean

container of fresh solvent.

Do not spin dirty bearings. Rotate

them slowly while washing.

d) Dry thoroughly cleaned bearings. If an air hose is

used for drying, make sure it is clean dry air.

Do not allow the bearings to spin by

force of air. Hold the inner and outer rings to

prevent bearing from spinning.

e) Inspect bearings immediately. If there is any

question as to the condition of a bearing do not

hesitate to replace it. There are many conditions

that contribute to the deterioration of the

bearings. A qualified bearing representative

should be consulted if there is any question of

bearing condition.

f) Inspected bearings which will be reused should

be packed with new grease or dipped in clean

lubricating oil, covered with clean lint free rags or

other suitable covering and placed in a clean box

or carton until ready for installation.

Under no circumstances the

bearings are to be left exposed.

g) Thoroughly flush and clean the oil passages,

then coat the inner surfaces with a thin film of

lubricating oil. Remove all scale and deposit in

the water circulation space, if provided, by

scraping and chemical treatment when

necessary. Cover the bearing bodies to keep

them clean until ready for installation

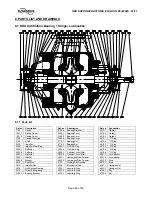

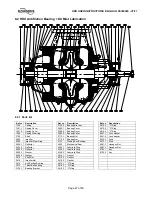

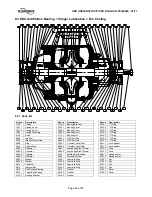

6.8.7.2 Sleeve Ball

Anti-friction bearings are slightly shrunk on the shaft

and a pulling device must be used to remove them.

The pulling jaws or fingers must be located behind

the shoulder of the inner race.

Unless extreme care is used when removing an anti-

friction bearing, the bearing may be damaged to the

extent that is no longer useable.

Always check the bearing immediately after removal

for any imperfections or any play between the races.

It is recommended that new bearings be used for

replacement of removed bearings since very often

damage caused by removal cannot be detected until

the pump is put into operation.

When mounting anti-friction bearings on the pump

shaft remember that the satisfactory operation of anti-

friction bearings requires that the inner be firmly held

on the shaft so that it cannot turn on the shaft.

Heat the bearing to expand the inner race and shrink

it on the shaft.

Place bearings on a shelf in a temperature controlled

oven. A temperature of 80° for one half hour should

be sufficient.

Care must be taken to keep the bearing clean and

uncontaminated.

Check the position of the bearing on the shaft with a

feeler gage to make sure it is pressing firmly against

the shoulder.

6.8.7.3 KTB

Babbitted sleeve bearings

The sleeve bearings supplied with the HDX pump are

of the split type and are easily removed or installed.

When removed, they should be cleaned in a suitable

solvent. Use rags or cloth, as waste leaves lint which

might cause trouble in the bearing.

A poorly cleaned bearing will score and wear out

rapidly. A bearing surface is not clean until a cloth

wiped over it shows no soil. Inspect all bearing parts

after cleaning. Remove, with a scraper, any bruises

on the babbitt faces before reassembling.

Kingsbury thrust bearing

For maintenance of the Kingsbury thrust bearing refer

to the manufacturer’s instructions.

6.8.8 Labyrinths or bearing isolators (if fitted)

a) The lubricant, bearings and bearing housing

seals are to be inspected for contamination and

damage. If oil bath lubrication is utilized, these

provide useful information on operating

conditions within the bearing housing.

b) If bearing damage is not due to normal wear and

the lubricant contains adverse contaminants, the

cause should be corrected before the pump is

returned to service.

c) Labyrinth seals and bearing isolators should be

inspected for damage but are normally non-

wearing parts and can be re-used.