HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 42 of 60

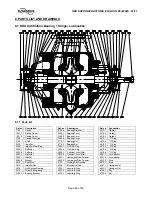

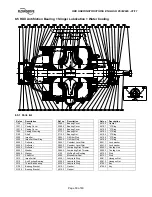

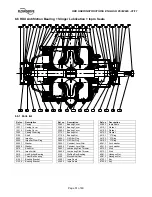

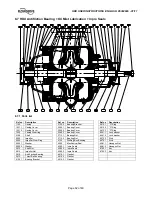

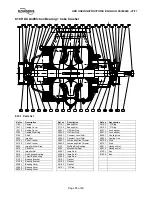

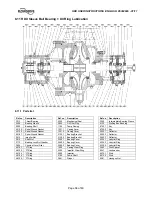

Figure 6.5

c) Install impeller locking nut. Use a pin spanner

wrench to tighten the nut.

d) Place rotor on “V” blocks or rolls and check with

dial indicator wear rings for high spots or run out

(0.13 mm max).

e) Replace shaft, complete with impeller through the

casing and inboard stuffing box; lifting gear will

help in this operation.

Care must be taken not to nick or

burr any components, especially running fits.

f) Place new gaskets onto the outboard stuffing box

cover flange and suction diaphragm, and offer

the stuffing box to the casing.

g) Replace nuts and washers and tighten evenly

until a face to face condition is achieved. Any

difficulty in pulling up the suction diaphragm

should be investigated.

h) From the non-drive end push the rotor as far

inboard as possible and scribe a line on the shaft

in line with the stuffing box machined face. From

the drive end push the rotor as far inboard as

possible and scribe another line on the shaft.

Move the rotor inboard again to halfway between

these lines. This is the rotating element centered.

i) Replace mechanical seal cartridge (do not

tighten).

6.9.3 Thrust and line bearings

It is most important that all parts to be

assembled have been thoroughly cleaned. Failure

to comply may cause serious damage to the

pump.

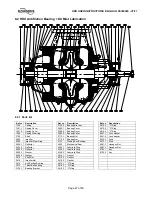

6.9.3.1 Ball Ball

a) Install oil shields from each end of shaft,

positioning them against their respective shaft

shoulder.

b) Fit inner bearing covers with their labyrinth ring in

place, and locate them against the shields.

c) Ensure that new gaskets are fitted.

d) Thrust and line bearings can now be fitted. Check

the duplex bearings are mounted back-to-back.

e) Fit slinger, lock-washers and lock nuts. Tighten

lock nuts and lock tab on lock-washers.

f) Install bearing housings sliding them over thrust

and line bearings.

g) Locate bearing housings to their respective

location on stuffing box brackets and tighten

bolting.

h) Fix both inner bearing covers to bearing

housings.

i) Position outer bearing covers and tighten bolting.

Ensure that new gaskets are fitted.

j) Set labyrinth ring on line bearing cover and

secure oil shield with set screws.

k) Install nuts securing mechanical seal plate

assembly to stuffing box at both ends of pump.

Tighten nuts evenly.

l) Finally set seal assemblies according the

manufacturer’s instructions.

m) Turn rotor by hand to ensure there are no rubs or

binding.

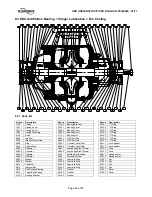

6.9.3.2 Sleeve Ball

a) Place new gaskets onto the outboard stuffing box

cover flange and suction diaphragm, and offer

the stuffing box to the casing.

b) Replace nuts and washers and tighten evenly

until a face to face condition is achieved. Any

difficulty in pulling up the suction diaphragm

should be investigated.

c) From the non-drive end push the rotor as far

inboard as possible and scribe a line on the shaft

in line with the stuffing box machined face. From

the drive end push the rotor as far inboard as

possible and scribe another line on the shaft.

Move the rotor inboard again to halfway between

these lines. This is the rotating element centred.

d) Replace mechanical seal cartridge (do not

tighten).

e) Install inner oil shields together with respective

labyrinth rings from each end of shaft, in their

respective position. Fit “O” rings in labyrinth rings.

Do not tighten oil shield set screws.

f) Slide in position onto shaft all sleeve bearing oil

rings.

g) Fit thrust bearing assembly. Check duplex

bearings are spaced and mounted back-to-back.

Install between bearings rotating and stationary

spacers together with the oil ring. Slide external

sleeve over the bearings and bolt it to the

stationary spacer. Make sure that side slot is in

top position to engage the parallel pin fitted on

the upper half of thrust bearing housing.

h) Fit lock washer and lock nut. Tighten lock nut and

lock tab on lock-washer.