HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 17 of 60

4.3.2 Method of levelling baseplate using wedges

or shims

a) Level the baseplate by using a machinist's level

on the machined surfaces of the pump and driver

pads. Levelling is best achieved by adjusting the

shim pack thickness under each holding bolt.

Carefully raise the baseplate by using either the

baseplate jacking screws provided or by levering

with a suitable pinch bar or by installing a low

level hydraulic jack.

b) Adjust the shim pack thickness and lower the

baseplate.

c) Repeat this procedure in a logical manner at

each bolt position until the baseplate is both

straight and levelled. A degree of 0.25 mm per

metre (0.0035 inch per foot) length is achievable

on most units with a maximum of 0.40 mm per

meter length (0.005 inch per foot).

d) In case of installation on steel structures (like

platforms) proceed with these extra steps:

•

Using a calibrated pin with a cone point mark

the centre of baseplate support pads

mounting holes on the soleplate.

•

Lift and move away the pump skid.

•

Drill and tap the soleplate fixing holes.

•

Replace the pump skid so that the soleplate

fixing holes align with the baseplate support

pads mounting holes.

•

Level the unit like done previously (see points

a, b, c).

e) When the baseplate is level, pull down the

foundation bolts so they are snug or tighten the

fixing bolts in case of installation on steel

structure. This may have disturbed the baseplate,

so re-check the levels.

Ensure that shaft alignment per Section 4.5 can be

achieved prior to grouting the baseplate.

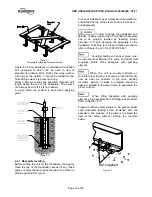

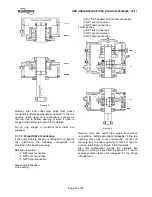

4.4 Grouting

Build a dam around the foundation as shown in

Figure 4.4 after levelling the baseplate. It is a matter

of personal preference whether the levelling wedges

under the baseplate should be removed after

grouting. If you do not want to remove the wedges,

carefully mark their locations before pouring grout.

Before grouting, level machined

pads of baseplate in both directions and perform

a rough shaft/coupling alignment. Alignment after

grout has set will not be possible if above is not

satisfactorily completed.

4.4.1 Fully Grouted Baseplates

DAM

CONCRETE

LEAVE TOP OF

FOUNDATION ROUGH

DO NOT FINISH

WITH TROWEL

FINISHED GROUT

GROUTING 1 TO 2

INCHES DEEP

Figure 4.4

Use a good, high strength, non shrink grout mix and

install as per manufacturer's instructions.

Holes are provided in the baseplate to permit pouring

the grout and stirring while acting as air vents. Fill

under the baseplate completely, stirring to assure

correct distribution of the grout. Check to see that the

grout flows under the edges of the baseplate evenly.

Do not vibrate baseplate when grouting,

making sure baseplate is vented correctly and all

areas are thoroughly puddle to prevent any resonant

problems.

When the grout is thoroughly hardened, remove the

dam and wedges, if desired, filling in the holes they

leave with grout.

Pour grout until level reaches top of dam.

Allow to dry sufficiently to prevent grout from

overflowing while completing the remaining grouting.

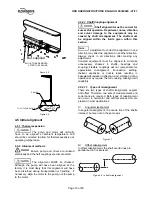

4.4.2 Baseplate not Intended for Grouting but

Installed on Concrete Foundations

According to the figure 4.3.1 and 4.4.1 the baseplate

will not be grouted but only a sealing shall be

provided. During the preparation, as indicated on the

General Arrangement drawing a certain number of

openings into the sealing must be guaranteed. After

the sealing the blocks used to realise the openings

must be removed. Blocks have to be wider than the

baseplate longitudinal beam in order to guarantee the

opening for the drainage.