HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 35 of 60

If the pump is supplied with a constant level oiler the

oil level will be automatically maintained and as long

as oil is visible in the glass bottle there is no need to

refill. If however a sight glass has been fitted then

regular checks should be made to ensure the level is

maintained at the centre of the glass window.

Refer to section 5.1.1 for methods of oil fill, section

5.2.1 for oil grade recommendations and 5.2.4 for the

schedule and temperature limits.

6.2.6 Mechanical seals

No adjustment is possible. When leakage reaches

an unacceptable level the seal will need replacement.

6.3 Spare parts

6.3.1 Ordering of spares

Flowserve keep records of all pumps that have been

supplied. When ordering spares the following

information should be quoted:

1)

Pump serial number

2) Pump

size

3)

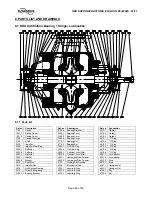

Part name (a)

4)

Part number (a)

5)

Number of parts required

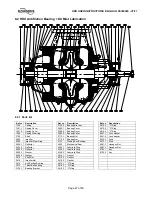

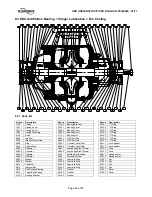

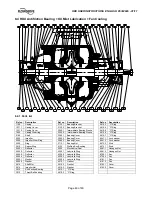

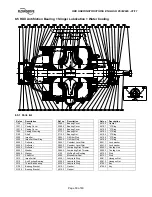

(a) Taken from the cross section drawing stored into

the job user instruction book and only in case not

available see at section 8.

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non-genuine part) will

invalidate the pump’s safety certification.

If rings are ordered as repair parts after

the pump has been put into service, undersized

stationary rings or oversized impeller rings will

not be furnished unless specifically requested by

the customer.

If undersize or oversize rings are desired, the amount

of undersize or oversize required on the I.D. or the

O.D. must be stated by the customer in the repair

order

.

It is recommended as insurance against delays that

spare parts be purchased at the time the order for the

complete unit is placed or as soon after receiving the

pump as possible.

6.3.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of

metallic surfaces (if necessary) with preservative is

recommended at 6 monthly intervals

6.4 Recommended spares (according to

API)

For start up purposes:

1 - set of bearings (line and thrust)

2 - sets of gaskets and o-ring

2 - wear rings set (2 ro 2 stationary)

1 - mechanical seals

1 - labyrinth set (drive and impeller end)

For normal maintenance:

1 - set of bearings (line and thrust)

2 - sets of gaskets and o-ring

2 - wear rings set (2 ro 2 stationary)

1 - mechanical seals

1 - labyrinth and deflector set

(drive and impeller end)

1 - shaft

1 - impeller

6.5 Tools required

A typical range of tools that will be required to

maintain these pumps is listed below

Readily available in standard tool kits, and dependent

on pump size:

•

Open ended spanners (wrenches) to suit up to 2”

(M 50) screws/nuts

•

Socket spanners (wrenches), up to 2” (M 50)

screws

•

Allen keys, up to 10 mm (A/F)

•

Range of screwdrivers

•

Soft

mallet

More specialized equipment:

•

Bearing

pullers

•

Bearing induction heater

•

Dial test indicator