HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 38 of 60

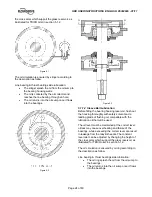

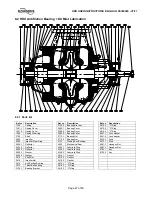

e) Carefully lift pump shaft just enough so that lower

half sleeve bearing can be removed.

f) Unbolt and remove lower half of line bearing

housing.

g) Unscrew set screws and remove inboard and

outboard oil shields together with labyrinth rings.

Remove oil rings.

6.7.3.3 KTB

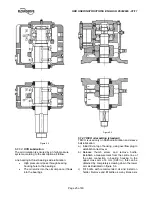

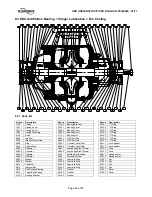

a) Remove all bolting and taper pins holding upper

half of line bearing housing and remove it. Use

jack bolts and eyebolts for removal.

b) Remove top half sleeve bearing.

c) Carefully lift pump shaft just enough so that lower

half sleeve bearing can be removed.

d) Unbolt and remove lower half of line bearing

housing.

e) Remove inboard and outboard labyrinth rings.

Unscrew set screws and remove inboard and

outboard oil shields.

6.7.4 Rotor disassembly

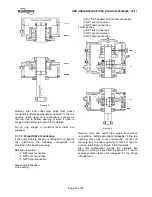

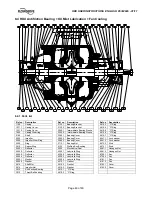

a) Remove nuts holding seal plates to stuffing box

at inboard and outboard pump end.

b) Clean shaft and carefully withdraw complete seal

cartridges from the shaft.

c) Unbolt and remove outboard stuffing box. Use

jack screws provided for the initial start of

removal. Support stuffing box using an eye bolt

and lifting gear, and remove from the casing

ensuring that it does not swing down and

damage the shaft.

d) Remove stuffing box gaskets.

e) The rotating element may now be withdrawn. It is

essential that this operation is carried out as

carefully as possible to avoid damage to the shaft

and wear rings.

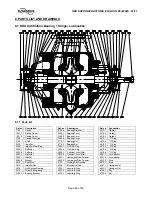

f) Unscrew the impeller locking nut using a pin

spanner wrench. Remove the nut.

g) Clean shaft and remove impeller as follows:

h) Apply heat to periphery of impeller until

temperature reaches 190°C (minimum) to 204°C

(maximum), then apply heat down through the

vane passages, thus heating the hub.

i) With periphery, shroud and hub at temperature,

remove impeller

If the impeller should grip the shaft

before it is above the fit, do not attempt to force it

the rest of the way, but instead allow the

assembly to cool to room temperature and then

reheat the impeller until it is free.

j) Remove impeller key.

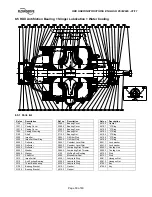

6.8 Examination of parts

Used parts must be inspected before

assembly to ensure the pump will subsequently run

properly.

In particular, fault diagnosis is essential to enhance

pump and plant reliability.

6.8.1 Casing and Covers

a) Inspect for excessive wear, pitting, corrosion,

erosion or damage and any sealing surface

irregularities. Remove all scale and deposit in

stuffing box water jackets by scraping and

chemical treatment where necessary. New

casing gasket should be installed whenever the

pump is disassembled.

b) Replace as necessary.