HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 10 of 48

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping documents

for its completeness and that there has been no

damage in transportation.

Any shortage and or damage must be reported

immediately to Flowserve and received in writing

within one month of receipt of the equipment. Later

claims cannot be accepted.

Check any crates, boxes and wrappings for any

accessories or spare parts which may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check that

this number corresponds with that advised and

always quotes this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork-lift vehicles or slings dependent on their

size and construction.

2.3 Lifting

Make sure that any equipment used to lift the pump

or any of its components is capable of supporting the

weights encountered. Make sure that all parts are

correctly rigged before attempting to lift.

A crane must be used for all pump sets in

excess of 25 kg (55 lb). Fully trained personnel must

carry out lifting, in accordance with local regulations.

The driver and pump weights are recorded on

general arrangement drawing included into the job

user’s instruction.

2.3.1 To Lift unit

Pump, driver and baseplate can be lifted as a unit.

Sling from all four (4) eye bolts provided on baseplate

side rails. Failure to use all four (4) could result in

permanent distortion of the baseplate. Use as long a

sling as possible, or use a spreader arrangement.

Coupling bolting and spacer piece

must be removed from between pump and driver

half couplings before lifting baseplate with

pumping element.

To lift pump and baseplate, less driver, or

baseplate alone, sling from all four (4) eye bolts.

Figure 2.1

Do not lift pump, motor, baseplate

unit by slinging from pump casing and/or eye bolt

on motor.

2.3.2

To lift driver

Refer to Manufacturers Instructions.

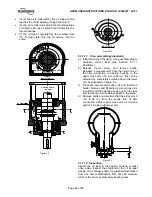

2.3.3

To lift complete pump only

Rig lifting straps at coupling end of bearing housing

and at suction nozzle. Make sure straps are adjusted

to obtain an even lift.

Figure 2.2

2.4 Storage

Store the pump in a clean, dry location

away from vibration. Leave piping connection covers

in place to keep dirt and other foreign material out of

pump casing. Turn pump at intervals to prevent

brinelling of the bearings and the seal faces, if fitted,

from sticking.

Electric Motors (Pump Driver) should not be stored in

damp places without special protection (Refer to

Motor manufacturers instructions).

The pump may be stored as above for up to 6

months.