HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 12 of 48

d) Depending upon the length of time the equipment

was stored, the type of storage provided (i.e.

Indoor: heated, unheated, ground floor, concrete

floor. Outdoors: under roof, no roof, waterproof

coverings, on concrete, on ground) and as a

result of the inspection of (a),(b) & (c) above the

FLOWSERVE representative may require a

partial or complete dismantling of the equipment.

e) Dismantling may necessitate restoration of

painted or preserved surfaces, and, or

replacement of gaskets, "O" rings, packing and

bearings.

f) All costs involved during inspection, dismantling,

restoration, replacement of parts and reassembly

will have to the accounted to the purchaser. All

necessary labour, tools and cranes will be

supplied by the purchaser.

Upon completion of the inspection the FLOWSERVE

representative shall submit a report to the purchaser,

and to the Manager of Customer Service, stating in

detail the results of the inspection.

One month prior to installation of the equipment, a

FLOWSERVE representative is to be employed to

conduct a final inspection. This inspection will be

made to assure that the requirements of the six

months inspection report were satisfactorily

completed and that the equipment is ready for

installation.

Upon completion of this inspection the FLOWSERVE

representative shall submit a final report to the

purchaser, and to the Manager of Customer Service,

advising the results of the final inspection.

All costs involved in conducting the final inspection

will have to the accounted to the purchaser.

Prior to and during start up, any requirements for the

services of an FLOWSERVE representative will

revert back to the original contract agreement for

equipment purchased, with revised costing.

2.4.1.4 Painting and preservation

Paints and preservatives used are either

FLOWSERVE standard or 'special' as required by the

contract specification. Refer to FLOWSERVE for the

description of paints and preservatives used on this

order if needed

2.4.1.5 Associated equipment

Motors, Turbines, Gears, etc., being supplied by

FLOWSERVE.

Generally rotors of associated equipment should be

blocked to relieve bearing loads. Storage should be

indoors and dry. See the specific manufacturers

storage requirements.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local regulations. If the

product contains substances which are harmful to the

environment, these should be removed and disposed

of in accordance with current regulations. This also

includes the liquids and or gases in the "seal system"

or other utilities.

Make sure that hazardous substances or

toxic fluids are disposed of safely and that the

correct personal protective equipment is used.

The safety specifications must be in accordance

with the current regulations at all times.

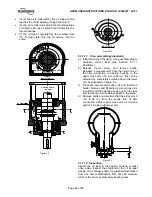

3 PUMP DESCRIPTION

3.1 Configurations

The type HPXM pump is a single stage, horizontal,

end suction process pump with overhung impeller

and radially split casing, fully compliant to API

610/682 The range is designed for continuous service

in all process applications including oil exploration

and production, oil refining, petrochemical, chemical

and general industrial usage.

3.2 Nomenclature

The pump size will be engraved on the nameplate

typically as below:

6-HPXM-12-A

Nominal discharge branch size

Pump type

Nominal full size impeller diameter

Casing pattern type

The typical nomenclature above is the general guide

to the HPXM description. Identify the actual pump

size and serial number from the pump nameplate.

Check that this agrees with the applicable certification

provided.

3.3 Design of major parts

3.3.1 Pump casing

The casing is centre line supported with end suction

and top discharge. It provides for the immediate

containment of liquid being pumped as the liquid is

directed from the suction nozzle through the impeller