HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 16 of 48

Figure 4.2

4.3.1 Baseplate levelling

Before putting the unit on the foundation, thoroughly

clean the top of the foundation. Break off any loose

pieces of cement and roughen the top with a chisel to

afford a good hold for grout.

In case of installation over a steel structure (platform)

ensure that the top of the steel structure is cleaned

and degreased.

In order to obtain the parallelism and

flatness of pads required by API standard, baseplate

has to be properly levelled by levelling screws

provided on it and clamping the baseplate at the

foundation bolts only (For proper detailed procedure

refer to Chapter 5 para 3.9.4 of API RP 686 ).

Coupling bolting and spacer piece must

be removed from between the pump and driver half

couplings before lifting baseplate with pumping

element

When the unit is mounted directly on

structural steel framing, it should be located directly

over as near as possible to the main building

members, beams, or walls. A soleplate should be

bolted or welded to the steel frame to guarantee the

proper surface.

When lifting baseplate with pumping

element, sling baseplate from all lifting lugs provided.

Refer to Section 2.3.1

Prepare sufficient steel plates to be placed below

each baseplate jacking screw furnished with the

baseplate. The purpose of the plate is to spread the

load of the screw without crushing the concrete

below.

Not supplied

Figure 4.3

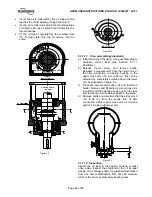

4.3.2 Method of levelling baseplate using wedges

or shims

a) Level the baseplate by using a machinist's level

on the machined surfaces of the pump and driver

pads. Levelling is best achieved by adjusting the

shim pack thickness under each holding bolt.

Carefully raise the baseplate by using either the

baseplate jacking screws provided or by levering

with a suitable pinch bar or by installing a low

level hydraulic jack.

b) Adjust the shim pack thickness and lower the

baseplate.

c) Repeat this procedure in a logical manner at

each bolt position until the baseplate is both

straight and levelled. A degree of 0.25 mm per

metre (0.0035 inch per foot) length is achievable

on most units with a maximum of 0.40 mm per

metre length (0.005 inch per foot).

d) In case of installation on steel structures (like

platforms) proceed with these extra steps:

•

Using a calibrated pin with a cone point mark

the centre of baseplate support pads

mounting holes on the soleplate.

•

Lift and move away the pump skid.

•

Drill and tap the soleplate fixing holes.

•

Replace the pump skid so that the soleplate

fixing holes align with the baseplate support

pads mounting holes.

•

Level the unit like done previously (see points

a, b, c).

e) When the baseplate is level, pull down the

foundation bolts so they are snug or tighten the

fixing bolts in case of installation on steel