HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 19 of 48

and loosen off the holding down bolt while noting any

deflection reading on the Dial Test Indicator - a

maximum of 0.05 mm (0.002 in.) is considered

acceptable but any more will have to be corrected by

adding shims, for example, if the Dial Test Indicator

shows the foot lifting 0.15 mm (0.006 in.) then this is

the thickness of shim to be placed under that foot.

Tighten down and repeat the same procedure on all

other feet until all are within tolerance

If the driver is an electric motor with sleeve

bearings then the magnetic centre at which the rotor

will run must be set. This is usually done by lining up

a groove in the shaft to a pointer fixed to the motor

body (refer to Motor Manufacture’s instructions).

4.5.2.3 Alignment using a graph (Reverse

Alignment)

Ensure pump and driver are isolated

electrically and the half couplings are disconnected.

The alignment MUST be checked.

Although the pump will have been aligned at the

factory it is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align the motor to the pump, not the pump

to the motor.

The alignment is achieved by adding or removing

shims under the motor feet and also moving the

motor horizontally as required. In some cases where

the alignment cannot be achieved it will be necessary

to move the pump before recommencing the above

procedure.

For couplings with narrow flanges use a dial indicator

as shown below to check both parallel and angular

alignment.

Parallel

Angular

Figure 4.11

Maximum permissible misalignment at working

temperature:

Parallel 0.05 mm (0.002 in.) TIR

Angular 0.025 mm (0.001 in.) TIR

Pumps with thick flanged non-spacer couplings can

be aligned by using a straight-edge across the

outside diameters of the coupling hubs and

measuring the gap between the machined faces

using feeler gauges, measuring wedge or calipers.

When the electric motor has sleeve bearings it is

necessary to ensure that the motor is aligned to run

on its magnetic centreline.

Refer to the motor manual for details.

A button (screwed into one of the shaft ends) is

normally fitted between the motor and pump shaft

ends to fix the axial position.

If the motor does not run in its

magnetic centre the resultant additional axial force

may overload the pump thrust bearing.

Complete piping as below and see sections 4.7,

“Final shaft alignment check”

up to and including

section 5,

“Commissioning, start-up, operation and

shutdown”

before connecting driver and checking

actual rotation.

4.5.3 Shims

The shims between the equipment feet and mounting

surface should be clean and dry. This is especially

critical for pumps in service for sometime and need to

be realigned. Water, dirt and rust may change the

height of the shim pack over a period of time. Shims

should be made large enough to support the weight

of the equipment on its mounting foot. Do not use

many thin shims as this may result in a spongy

mounting.

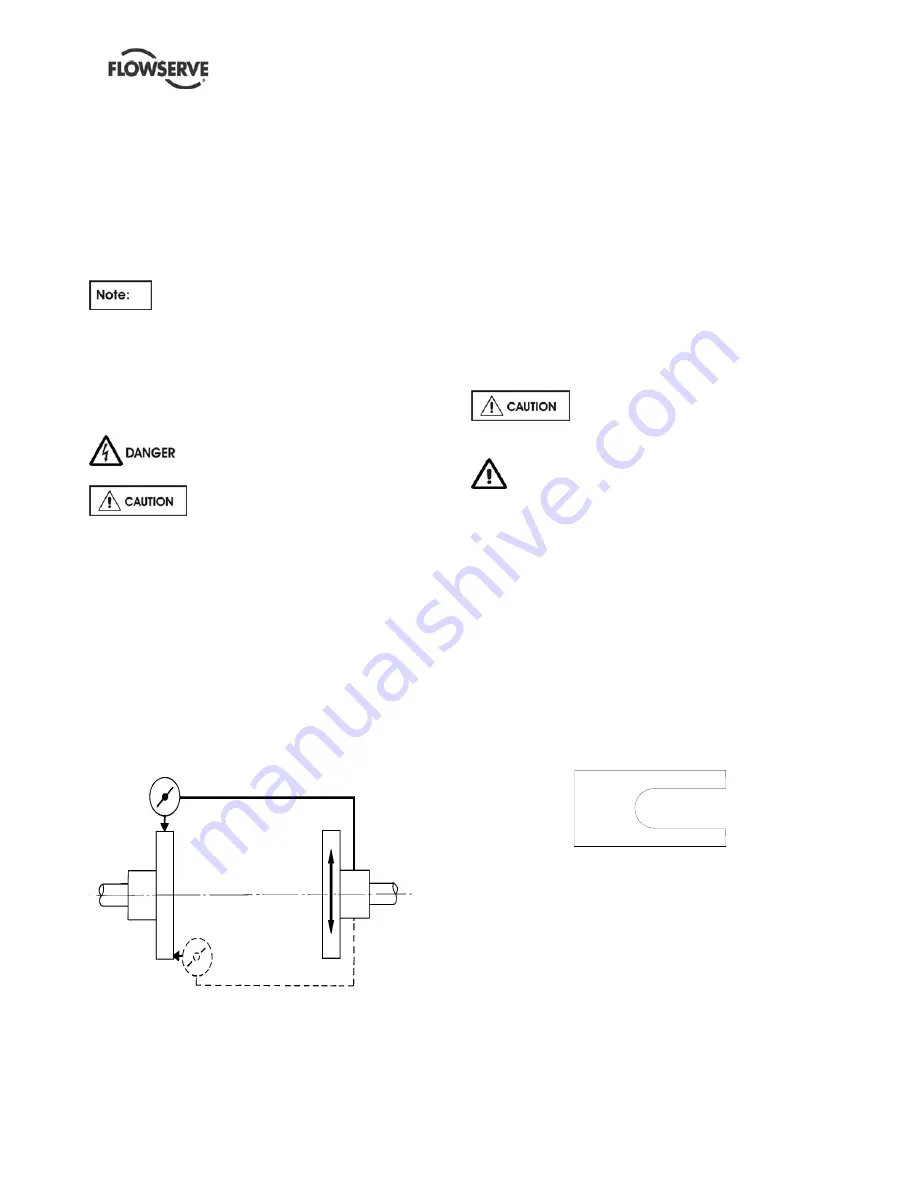

Figure 4.12

Recommended shim design

Move the equipment vertically by adding or removing

the calculated thickness of shims. Torque holding

down bolts to required values.

4.5.4 Hot alignment – Pump and driver dowels

Pump hold down bolts are to be torqued down and

dowel pins are to be located in pump feet as Figure

4.10. (This is only applicable if Hot Alignment is

required)