HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 20 of 48

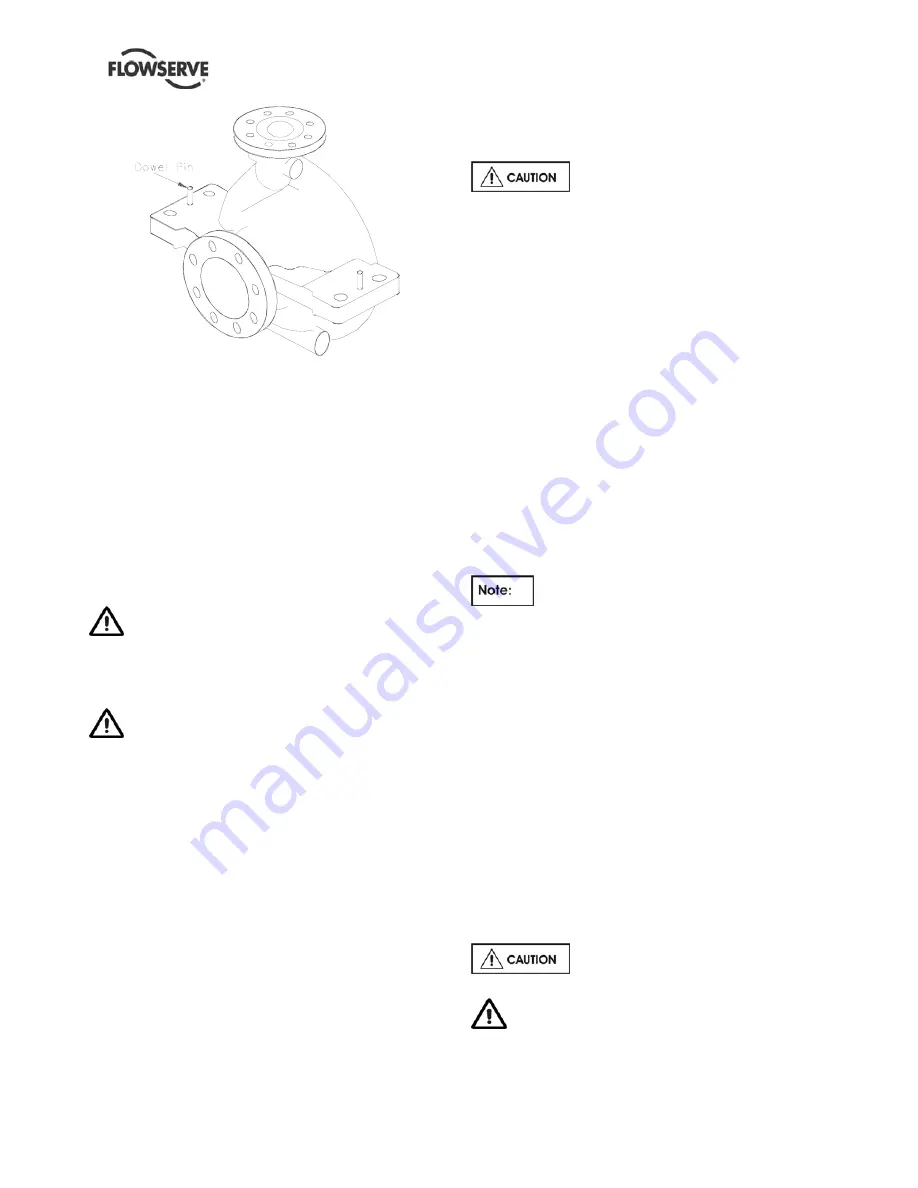

Figure 4.13

Pump Dowel pin location

Refer to driver outline drawing and/or driver

instructions for driver doweling information.

A hot check can only be made after the unit has been

in operation a sufficient length of time to assume its

NORMAL operating temperature and conditions. If

the unit has been correctly cold set, the offset

misalignment will be within 0.05 mm TIR (0.002 in.

TIR) and the angular misalignment will be within

0.025 mm TIR (0.001 in. TIR) when in operation. If

not make adjustments

Do not attempt any maintenance,

inspection, repair or cleaning in the vicinity of

rotating equipment. Such action could result in

injury to operating personnel.

Before attempting any inspection or repair

on the pump the driver controls must be in the

"off" position, locked and tagged to prevent

restarting equipment and injury to personnel

performing service on the pump.

4.5.5 Assemble coupling

a) Assemble coupling as per the manufacturer's

instructions included in Appendix of this manual.

b) Install coupling guard

4.5.6 Installation check list

a) Level

Baseplate?

b) Grout Baseplate - Check Foundation Bolts?

c) Alignment

Shaft/Coupling?

d) Piping Installed - Correct Vent, Gauge, Valve,

Suction Strainer Locations?

e) All Flange Bolting Correctly Torqued with

appropriate gaskets in place?

f) Check Shaft/Coupling Alignment again.

g) Coupling guard correctly installed?

4.6 Piping

Never use the pump as a support for

piping

4.6.1 General

These units are furnished for a particular service

condition. Changes in the hydraulic system may

affect performance adversely. This is especially true if

the changes reduce the pressure at the suction or if

the liquid temperature is increased. In case of doubt

contact FLOWSERVE

Suction and discharge piping should be of ample

size, be installed in direct runs, and have a minimum

of bends. Double bends must be avoided in suction

line and a straight run of pipe, equal 8 to 10 times the

pipe diameter is desired directly upstream of the

suction nozzle.

In order to minimise friction losses and hydraulic

noise in the pipework it is good practice to choose

pipework that is one or two sizes larger than the

pump suction and discharge. Typically main

pipework velocities should not exceed 2 m/s (6 ft/sec)

suction and 3 m/s (9 ft/sec) on the discharge.

Provision must be made to support piping

external to the pump to prevent excessive nozzle

loads, maintain pump/driver alignment and avoid pipe

induced vibrations.

Take into account the available NPSH which must be

higher than the required NPSH of the pump.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. To

minimize these forces and moments that may, if

excessive, cause misalignment, hot bearings, worn

couplings, vibration and the possible failure of the

pump casing, the following points should be strictly

followed:

•

Prevent excessive external pipe load

•

Never draw piping into place by applying force to

pump flange connections

•

Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal of the pump.

4.6.2 Suction piping