HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 21 of 48

a) The inlet pipe should be one or two sizes larger

than the pump inlet bore and pipe bends should

be as large radius as possible.

b) Keep the suction pipe free of all air pockets.

(Vent is required).

c) Pipework reducers should have a maximum total

angle of divergence of 15 degrees.

d) The piping should be inclined up towards the

pump inlet with eccentric reducers incorporated

to prevent air locks.

e) Flow should enter the pump suction with uniform

flow, to minimise noise and wear.

f) Except if considerable foreign matter is expected

strainers are not recommended in inlet piping.

Inlet strainers, when used, should have a net

“free area” (see section 4.6.2.1)

4.6.2.1 Suction strainer

In a new installation, great care should be taken to

prevent dirt, scale, welding beads and other items

from entering the pump, as it is particularly important

to protect the numerous close running fits from

abrasive matter present in new piping

The suction system should be thoroughly flushed

before installing the suction strainer and making up

suction piping to the pump.

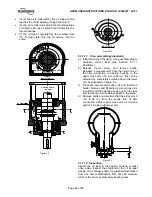

The suction strainer should be installed between 5 to

20 pipe diameters upstream from the pump suction

flange.

The open area of the strainer should

have a minimum of a 3 to 1 ratio to the area of the

pump suction.

Figure 4.14

Cone Type Strainer

The FLOWSERVE recommendation for suction

strainers consists of a conical shaped steel plate. The

plate has 1.6 mm (1/16 in.) perforations and is of

sufficient size and thickness for the required flow.

See Figure above.

Other type of strainers may be used as long as they

conform to the requirements stated above.

Pressure gauges should be installed on both sides of

the screen so that the pressure drop across the

screen can be measured.

When the unit is being started, the gauges on each

side of the screen should be carefully watched. An

increase in the differential pressure between the two

gauges indicates that the screen is becoming clogged

with dirt and scale. At this point, the pump should be

shut down, and the screen cleaned and/or replaced.

A spool piece should be installed in

suction line so that the suction strainer may be

installed and removed with a pressure gauge

between the strainer and pump.

4.6.2.2 Bypass Line

Operation at low flows results in

pump horsepower heating the liquid. A bypass

may be required to prevent vaporisation and

subsequent pump damage. Refer to local

FLOWSERVE branch to determine if a bypass is

required. Mechanical damage may result from

continuous operation at flows less than specified.

4.6.3 Discharge piping

a)

Install a check valve and a gate valve in the

discharge pipe of the pump. When the pump is

stopped, the check valve will protect the pump

against excessive pressure and will prevent the

pump from running backward. The check valve

should be installed between the gate valve and

the pump nozzle in order to permit its inspection.

Never throttle pump on suction side and never

place a valve directly on the pump inlet nozzle.

b) Pipework reducers should have a maximum total

angle of divergence of 15 degrees.

4.6.4 Drains

Pipe pump casing drains and gland leakage to a

convenient disposal point.

4.6.5 Pumps fitted with mechanical seals

Cartridge mechanical seals are provided, to seal the

shaft against leakage. The seals used on the

"HPXM" pump have internal design differences for

sealing against specific liquids and conditions.

Long seal life with minimal leakage can only be

obtained if the seals are provided with clean, cool

liquid. Even tiny solids that may be suspended in the

liquid being pumped can damage the seal faces and

cause the seal to leak, making an external flush or a

different seal arrangement necessary. The seal

balancing and flushing arrangement provided for