HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 23 of 48

b) Ensure the pump and piping is clean. Before

putting the pump into operation, the piping should

be thoroughly back flushed to remove any foreign

matter which may have accumulated during

installation. Take all possible care not to

contaminate your system.

c) Install suction strainer if required. (See Section

4.6.2.1).

d) Fill the bearing housing with the appropriate oil to

the correct level. Bearing must receive a small

amount of oil prior to starting to ensure adequate

lubrication at start up. (Refer to Section 5.1.1).

e) Turn pump rotor by hand or with a strap wrench

to make sure it turns smoothly.

f) Assure that correct seal piping has been installed

and has not been damaged.

g) Prior to coupling installation, bump start motor to

check for correct rotation. If rotation is not correct

refer to motor manual for appropriate connections

to change rotation (Shut down all power prior to

change).

h) Ensure coupling is correctly aligned and

lubricated, and pump and driver is satisfactorily

doweled. (Refer to Section 4.5).

i) Ensure coupling guard is correctly installed.

The unit must not be operated unless

coupling guard is securely and completely bolted

in place. Failure to observe the warning could

result in injury to operating personnel.

j) Check torque of all bolting and the plugs for

tightness

5.1.1 Lubrication

Lubrication of bearing is by oil circulation into the

bearing housing provided by oil ring, slinger or pure

oil mist. A constant level oiler is normally furnished

(except for pure oil mist lubrication) with the pump

unless otherwise specified.

5.1.1.1 Oil ring or Slinger Lubrication

Before filling the bearing housing reservoir, flush out

the housing thoroughly with safety solvent and a

leading grade of flushing oil, compatible with the

lubricating oil that will be used. The reservoir is to be

filled to appropriate level as illustrated in section

5.1.1.1.5

Figure 5.1

Figure 5.1

D1: oiler connection with slinger lubrication

C1: overflow plug with slinger lubrication

D2: oiler connection with oil ring lubrication

C2: overflow plug with oil ring lubrication

The oil level must be maintained at the correct level:

oil lack may cause overheating and failure of the

bearings, while exceeding the correct level can result

in leakage from the labyrinth seals. The constant

level oiler can be adjusted by changing the height of

the cross arms which support the glass reservoir, as

illustrated for TRICO oiler in section 5.1.1.1.1

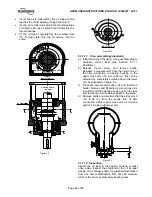

The oil circulation is ensured by slinger or oil ring

according to the description as follow (see figure 5.2).

Line bearing side lubrication

•

(1)-(2) the slinger (or oil ring if supplied) splash

the oil from the oil sump to the bearing housing

walls

•

(3)-(4) the oil is collected by the oil collector and

reaches the line bearing through the hole “E”

•

(5) the oil returns into the oil sump once it flows

into the line bearing

Thrust bearings side lubrication

•

(1)-(2) the slinger (or oil ring if supplied) drives

the oil from the oil sump to the bearing housing

wall