HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 24 of 48

•

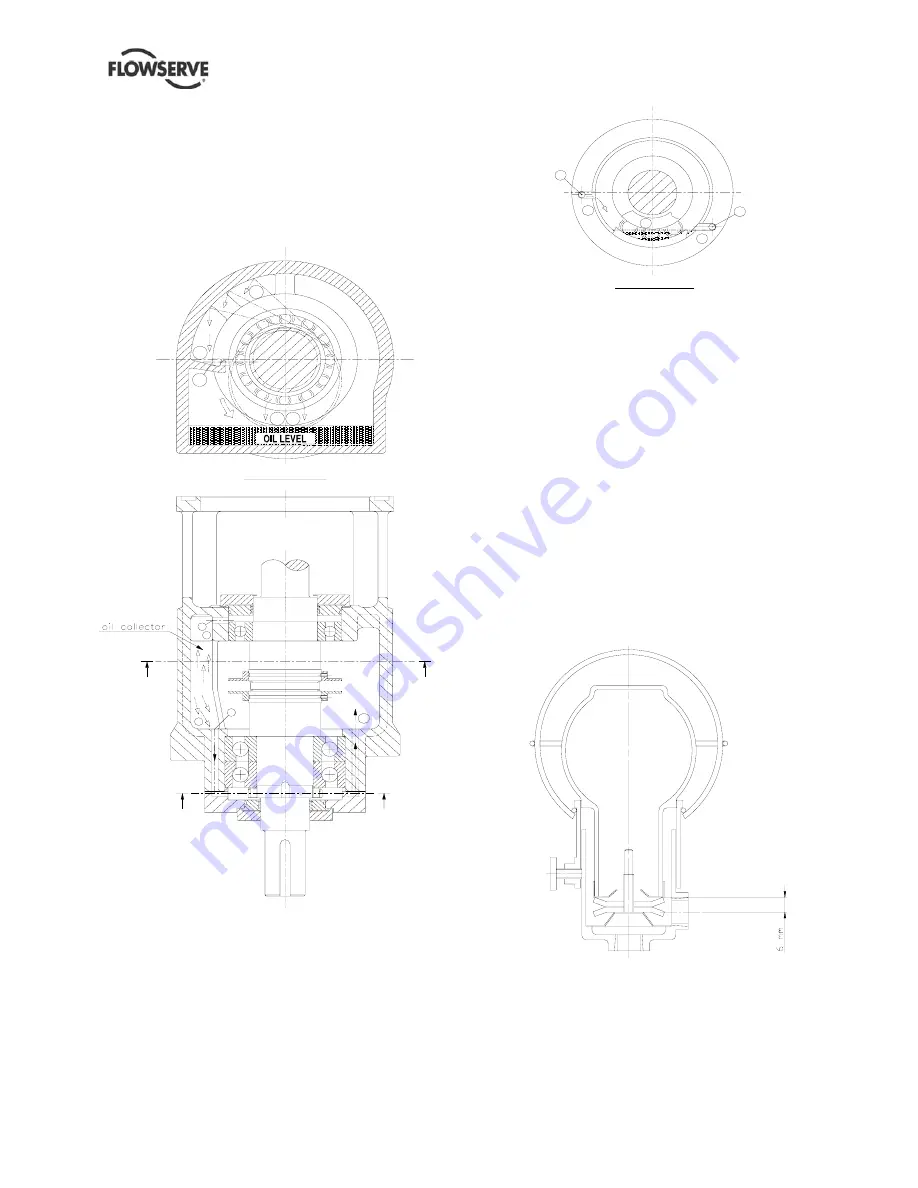

(3)-(4) the oil is collected by the oil collector and

reaches the thrust bearing through the hole “F”

•

(6) the oil is collected behind the thrust bearings

and returns into the oil sump once it flows into the

thrust bearings

•

(7) the oil level is regulated by the overflow hole

“G”. Through this hole the oil returns into the

sump.

A

B

SECTION A − A

1

2

3

E

E

4

5

B

A

F

bearing frame

top view

G

4

Figure 5.2

SECTION B − B

F

4

6

7

G

Figure 5.2

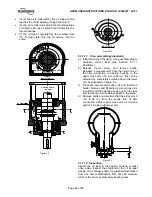

5.1.1.1.1 Trico oiler setting (standard)

a) Initial fill via top of housing, using overflow plug to

establish correct level (see Section 5.1.1.1

illustration).

b) Release thumb screw and remove bottle.

Establish a measurement from the centre line of

the oiler connection in bearing housing to the

upper cross arm of 6 mm (0.24 in.); this can be

obtained by completely screwing down the lower

arm as illustrated on figure 5.3.

c) Fill bottle with recommended oil and install on

holder. Remove and fill bottle as many times as is

required to fill the bearing housing up to the cross

arm level and no air bubbles appear in the bottle.

d) Remove bottle and ascertain that the oil level is 6

mm (0.24 in.) from the centre line of oiler

connection. Adjust upper cross arm as required

and lock in place with lower arm.

Figure 5.3

5.1.1.1.2 Inspection

Inspect the oil level in the bearing housing at least

once a day. Inspect the condition of the oil at least

weekly. Oil is always subject to gradual deterioration

from use and contamination from dirt and moisture

which is the cause of premature bearing wear.