HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 25 of 48

For oil lubricated pumps, fill the

bearing housing with correct grade of oil to the

correct level, i.e. constant level oiler bottle (standard

configuration) and sight glass (when fitted on

request).

Figure 5.4

Sight glass

5.1.1.1.3 Replenishment

Replenish the oil in the oiler as required. More

frequent replenishment at high temperatures may be

required.

5.1.1.1.4 Oil change

Frequency of oil change is dependent on pump

service and environmental conditions. As a general

guide, oil in the bearing housing should be changed

every 4000 operating hours, after the initial change.

5.1.1.1.5 Lubrication Specification

The ideal bearing lubricant is a straight well refined,

neutral mineral, preferably of the turbine type. It

should not contain free acid, chlorine sulphur or more

than a trace of free alkali. It is suggested that the oil

conform to the following physical characteristics.

5.1.1.2 Pure Oil Mist Lubrication

If the pump bearing housing is arranged for pure oil

mist lubrication the following connections are

provided in the bearing housing:

-

¼” NPT with adapter oil mist inlet connection in

the top half of the bearing housing, between line

and thrust bearings.

-

¼” NPT vent connection in the space between

the rolling element bearing and the

inboard/outboard bearing housing cover.

-

½” NPT drain connection in the bottom half of the

bearing housing.

Remove inlet and outlet pipe plugs from above

connections. Install appropriate reclassifier in the top

opening, leave open vent connections, connect oil

recovery trap to bottom opening or leave it open to

act as a relief. Refer to Figure 5.5 for details.

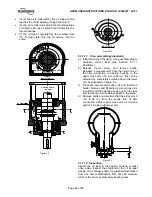

Figure 5.5

No oil ring, slinger or constant level oiler are supplied.

5.1.1.3 Purge Oil Mist Lubrication

If the pump bearing housing is arranged for purge oil

mist lubrication the following connections are

provided in the bearing housing:

-

¼” NPT with adapter oil mist inlet connection in

the top half of the bearing housing, between line

and thrust bearings.

-

¼” NPT vent connection in the space between

the rolling element bearing and the

inboard/outboard bearing housing cover.

-

½” NPT drain connection in the bottom half of the

bearing housing.

Remove inlet and outlet pipe plugs from above

connections. Install appropriate reclassifier in the top

opening, leave open vent connections, connect oil

recovery trap to bottom opening or leave it open to

act as a relief. Refer to Figure 5.5 for details.

Also this configuration include the internals like

slinger or oil ring as specified in section 5.1.1.1 and a

special constant level oiler designed for the Purge

arrangement.