HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 27 of 48

If a synthetic lubricant (fire resistant fluid) is to be

used instead of the normal type oil for the lubrication

of bearings, gears etc., the material of all gaskets and

"O" rings in contact with the lubricant must be

compatible with the lubricant. Normal gasket

materials will usually swell and deteriorate when

immersed in synthetic lubricants: also normal paints

will peel from internal walls of reservoirs and bearing

chambers.

In case of Pure Oil Mist lubrication the lubricant oil

should be rust and oxidation inhibited and stray mist

suppressed, manufactured in accordance with good

commercial practice. The viscosity should be ISO VG

100. Recommended Oil Suppliers are according to

the previous list

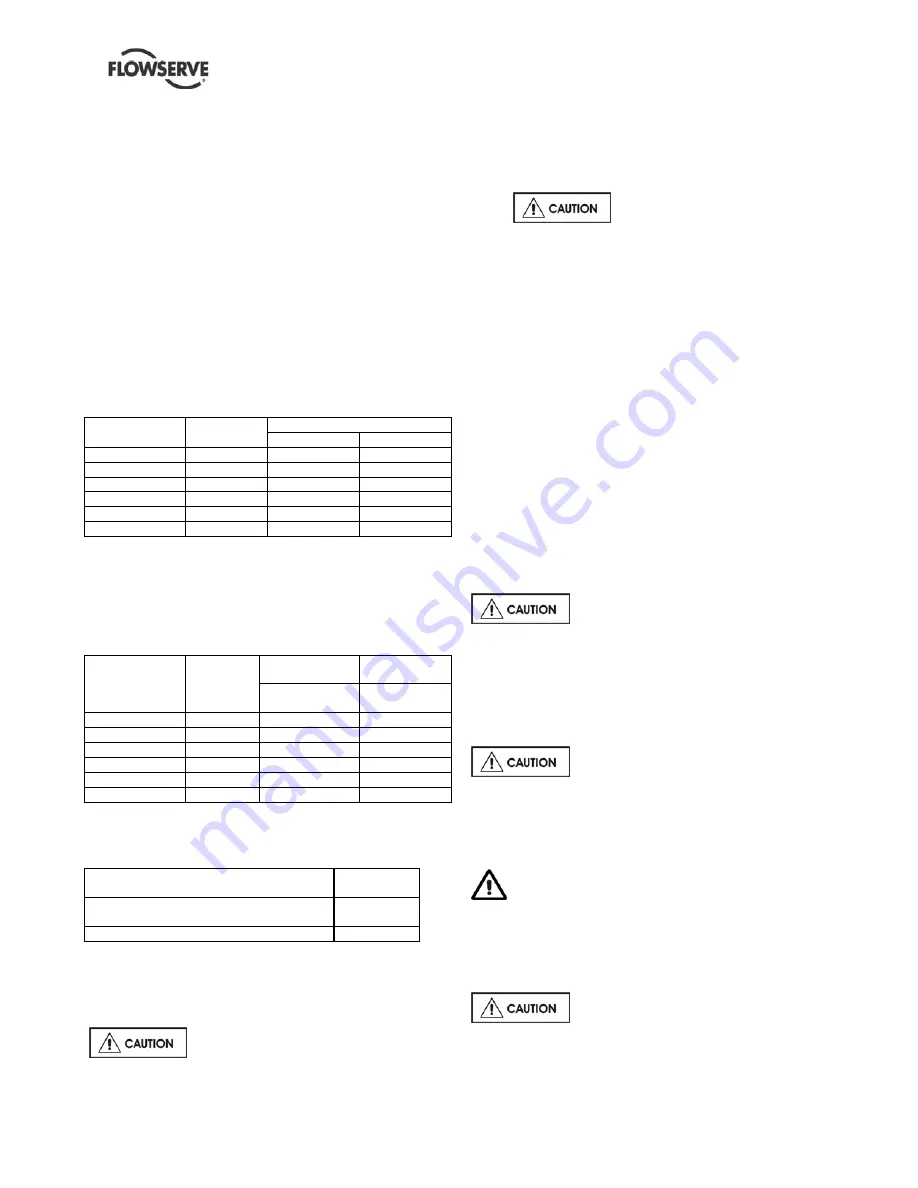

5.2.2 Recommended fill quantities

Oil Fill Capacities litres (fl. oz.)

Bearing Housing

Size (*)

Bearing

Designation

Slinger

Oil Ring

G040B159

7308

1.51 (51.05)

1.13 (38.21)

G050B159

7311

1.34 (45.31)

0.85 (28.74)

G070B159

7314

1.83 (61.87)

1.02 (34.49)

G090B159

7315

4.43 (149.78)

2.82 (95.34)

G090B159

7316

4.17 (140.99)

2.60 (87.91)

G105B159

7320

6.5 (219.76)

4.5 (152.15)

Oil Slinger or Oil Ring

* The bearing housing size can be identified from the

identifying marks cast on the housing

on the

horizontal centre line in the opposite side to the oiler

and from the thrust bearing side indicated by

nameplate.

MIST

Consumption

OIL

Consumption

Bearing Housing

Size (*)

Bearing

Designation

l/min

(feet

3

/min)

cc/min

(inch

3

/min)

G040B159

7308

6 (0.212)

0.024 (0.049)

G050B159

7311

8.5 (0.300)

0.034 (0.069)

G070B159

7314

11 (0.388)

0.044 (0.089)

G090B159

7315

11 (0.388)

0.044 (0.089)

G090B159

7316

12.5 (0.441)

0.05 (0.101)

G105B159

7320

15.25 (0.539)

0.06 (0.122)

Pure and Purge Oil Mist

5.2.3 Bearing housing oil limitations

Recommended Oil Temperature At Start Up

15.6 °C

60 °F

Desirable Operating Temperature

60-71 °C

140-160 °F

Oil Level Above Oil Connection Centre line

6 mm

When the starting temperature is below -10 °C (14

°F) for long time it’s suggested to use synthetic oil.

Other drivers and gearboxes, if appropriate, should

be lubricated in accordance with their manuals.

In the case of product lubricated

bearings the source of product supply should be

checked against the order. There may be

requirements for an external clean supply, particular

supply pressure or the commencement of lubrication

supply before pump start-up.

5.2.4

Lubrication schedule

5.2.4.1 Oil lubricated bearings

Normal oil change intervals are 4000 operating hours

or at least every 6 months. For pumps on hot service

or in severely damp or corrosive atmosphere, the oil

will require changing more frequently. Lubricant and

bearing temperature analysis can be useful in

optimising lubricant change intervals.

The lubricating oil should be a high quality mineral oil

having foam inhibitors. Synthetic oils may also be

used if checks show that the rubber oil seals will not be

adversely affected.

Based on the specified operating conditions and an

ambient temperature of 43°C (110°F) for ring-oiled or

splash systems, oil sump temperature below 82

°

C

(180°F) is expected.

A continuously rising temperature, or an abrupt rise,

indicates a fault.

5.3 Direction of rotation

Ensure the pump is given the same

rotation as the pump direction arrow fit on bearing

housing. In any case the direction of rotation must be

checked with the pump disconnected.

To avoid dry running the pump must either be filled

with liquid or have the flexible coupling disconnected

before driver is switched on.

If maintenance work has been carried

out to the site's electricity supply, the direction of

rotation should be re-checked as above in case the

supply phasing has been altered.

5.4 Guarding

Guarding is supplied fitted to the pump set. If

this has been removed or disturbed ensure that all the

protective guards around the pump coupling and

exposed parts of the shaft are securely fixed.

5.5 Priming and auxiliary supplies

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.