HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 33 of 48

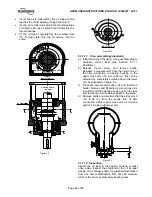

Inboard/Outboard Flingers & Oil Thrower

Torque Value

Socket Head

Capscrew Size

N

y

m

(lb

y

ft)

¼ in.

4-5

(3-4)

Torque Values listed above are selected to achieve

the correct amount of pre-stress in the threaded

fastener. Maintenance personnel must ensure that

threads are in good condition (free of burrs, galling,

dirt, etc.) and that commercial thread lubricant is

used. Torque should be periodically checked to

ensure that it is at the recommended value.

6.7 Disassembly

Refer to section 1.6,

Safety

, before dismantling

the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawings for part

numbers and identification.

Before attempting to disassemble the pump,

the pump must be isolated from the system, by

closing suction and discharge system valves,

drained of liquid and cooled, if pump is handling

hot liquid.

Before attempting any maintenance work on

pumps in vacuum service, the pumps must be

isolated from suction and discharge system then

carefully vented to return pressure in pump

casing to atmospheric pressure.

Remove the pipe plug(s) from the

top of the bearing housing(s) and check to see

that oil rings are riding free on the pump shaft

and are not hung up. Failure to observe this

caution could result in damage to or destruction

of equipment.

6.7.1 Disassembly of Pull Out Element

This is a pull from rear design, so it is not necessary

to remove casing, or to detach suction or discharge

piping, coupling hubs or to remove driver.

a) Remove all seal piping, related instrumentation

and electrical equipment that will interfere with

disassembly. Drain pump casing.

When pump is handling "hot" liquid extreme

care must be taken to ensure safety of personnel

when attempting to drain pump. Hot pumps must

be allowed to cool before draining.

When pump is handling "caustic" liquid

extreme care must be taken to ensure safety of

personnel when removing auxiliary piping or

when draining pump. Protective devices of

suitable protective materials must be worn when

draining the pump.

b) Disassemble and remove coupling guard and

coupling spacer.

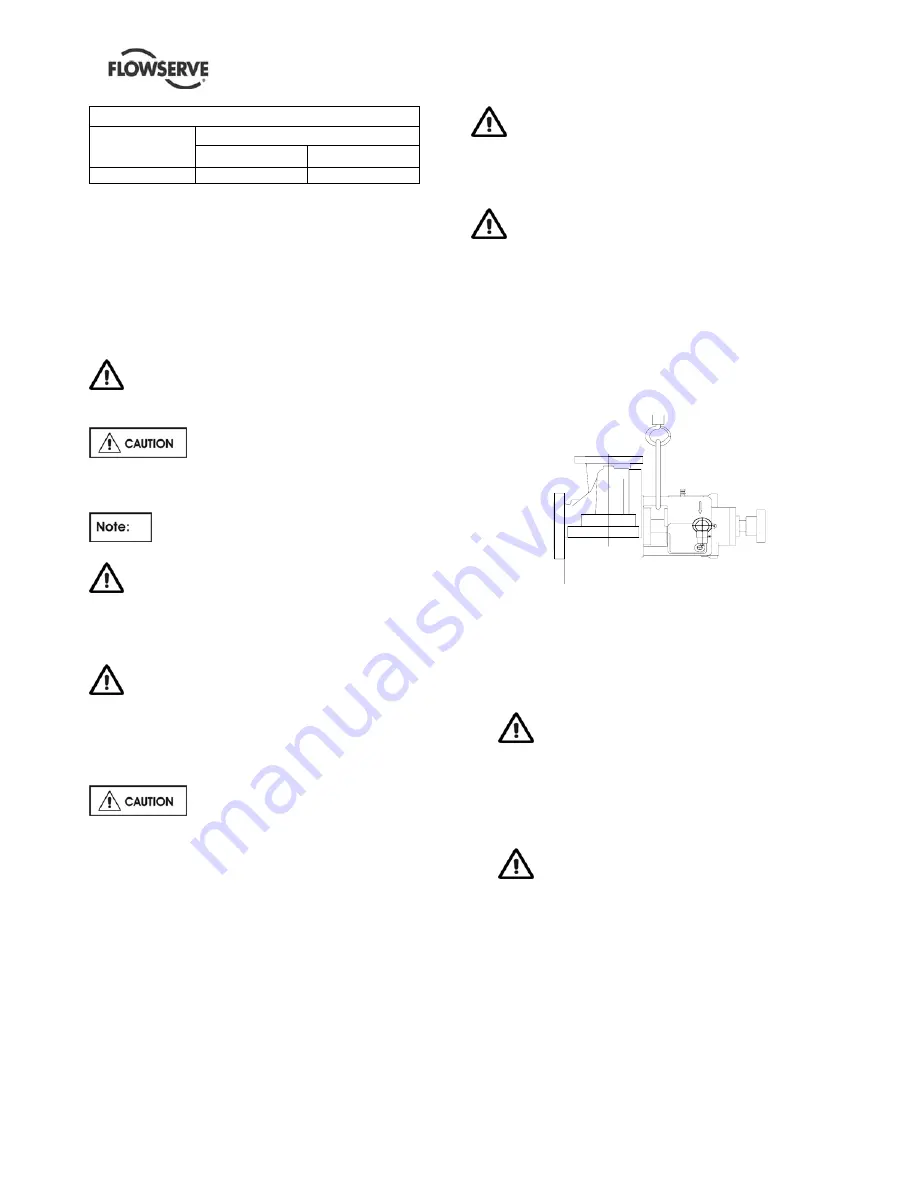

c) Place lifting straps around bearing bracket at seal

area. Take a slight strain on slings.

Figure 6.1

location of lifting straps for removing pumping element

d) Drain the bearing housing of oil. This can be

done by removing the drain plug situated at the

bottom of the bearing housing.

Use caution when draining hot oil from

bearing housing to prevent burns/injury to

personnel

e) It is advisable to thoroughly drain and dry off the

baseplate before attempting any maintenance

work on the pump.

This could eliminate the risk of slipping

on a wet surface causing personal injury or

mechanical damage.

f) Remove casing cover to casing main flange

bolting. Install two jack screws (provided) in

casing cover. Tighten jack screws evenly to

separate joint between casing cover and casing.

g) Carefully withdraw pumping element from casing

until impeller (or inducer when fitted) is clear of

casing. Move pumping element to area where

disassembly will be performed.