HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 34 of 48

h) Correctly support pumping element in horizontal

position. For non-inducer machines release

impeller locking screws and locknut on impeller.

For machines fitted with an inducer, release cap

nut then remove security washer.

Locking devices have left hand

thread form

i) Remove inducer (if fitted) and impeller.

j) Remove and discard gasket from casing cover.

Now rotate assembly so that the shaft axis is in

the vertical plane with coupling end uppermost.

6.7.1.1 Mechanical seal disassembly

a) Refer to mechanical seal drawing (in the job’s

user instruction) and identify the seal setting

plates on the front of the gland plate.

b) Rotate (or slide as appropriate for the design) the

plates into the mechanical seal sleeve setting

groove and then secure.

c) Slacken the screws locking the collar/seal sleeve

onto the pump shaft.

d) Unscrew any pipework from the tapped ports on

the periphery of the gland plate.

e) Remove the cap screws which secure the casing

cover to the bearing housing.

f) With the casing cover suitably supported carefully

remove the bearing housing and place

horizontally on flat surface.

g) Remove the four nuts securing the gland plate to

the casing cover. Returning to the casing cover

(with the gland plate uppermost). Note - When

oil ring lubrication is provided an additional ½"

NPT plug is fitted in the top of the bearing

housing adjacent to the mushroom headed vent.

Removal of the plug should enable the visual

inspection of the ring.

h) Remove mechanical seal cartridge assembly.

Refer to any special instructions supplied with

the mechanical seal.

6.7.1.2 Bearing housing disassembly

a) Looking at the bearing housing, remove impeller

key (and throat bush if fitted). If a cooling fan is

fitted, then remove the three locking screws

securing the fan to the outboard deflector.

Withdrawal the fan from the coupling end of the

shaft.

b) Loosen clamping screws and remove both the

deflectors from pump shaft.

c) Remove cap screws from bearing end covers,

securing cover to bearing housing.

d) Remove bearing end covers remove and discard

gasket. Remove labyrinth from bore of outboard

end cover. Remove o-ring from labyrinth.

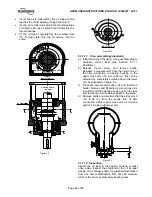

e) Place the bearing housing in a vertical position,

(coupling end up) on blocking. Blocking must be

of sufficient height to prevent shaft end from

contacting the floor. To avoid damage to the oil

rings, (when fitted) position them as shown.

Figure 6.2

f) Remove the shaft assembly from coupling end of

bearing housing. Remove labyrinth from seal end

of bearing housing. Remove o-ring from labyrinth.

Take care not to damage the oil

rings.

g) Release locking tab of lock washer. Remove

locknut and lock washer.

h) Bearings can be removed by the use of a press

or puller. Bearing must be installed in the same

manner as removed. It is suggested that each

bearing be marked for sequence and direction.

When removing bearings exert

pressure on inner race only. Do not exert any

pressure on outer bearing race. (See Section

7.6).

i) Remove oil rings and oil throwers from the shaft

as appropriate.

j) Check the shaft for run out using "V" blocks or

rollers placed under the bearing areas. Run out

of shaft is not to exceed 0.05 mm TIR (0.002

in.TIR).