HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 16 of 39

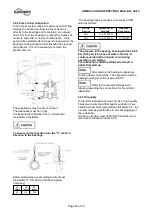

4.5.3 Drain

This connection is used for total drainage of the pump

casing. A flanged drain is standard and can be

optionally equipped with various kinds of valves.

Refer to GA drawing for details of the drain

connection.

By pumping toxic or explosive

media, provide the necessary security actions, e.g.

flushing with nitrogen.

4.6 Electrical connections

Electrical connections must be made by a qualified

Electrician in accordance with the relevant local

national and international regulations.

It is important to be aware of the EUROPEAN

DIRECTIVE on hazardous areas where compliance

with IEC60079-14 is an additional requirement for

making electrical connections.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used

during wiring/installation do not increase

electromagnetic emissions or decrease the

electromagnetic immunity of the equipment, wiring or

any connected devices. If in any doubt contact

Flowserve for advice.

The motor must be wired up in accordance with the

motor manufacturer's instructions (normally supplied

within the terminal box) including any temperature,

earth leakage, current and other protective devices

as appropriate. The identification nameplate should

be checked to ensure the power supply is

appropriate.

A device to provide emergency stopping must

be fitted.

If not supplied pre-wired to the pump unit the

controller/starter electrical details will also be supplied

within the controller/starter.

For electrical details on pump sets with controllers

see the separate wiring diagram.

See section 5.5,

Direction of

rotation

before connecting the motor to the electrical

supply.

4.7 Final shaft alignment check

After connecting piping to the pump, rotate the shaft

several times by hand to ensure there is no seizure

and all parts are free.

Recheck the coupling alignment, as previously

described, to ensure no pipe strain. If pipe strain

exists, correct piping.

5.0 COMMISSIONING START-UP,

OPERATION AND SHUTDOWN

These operations must be

carried out by fully qualified personnel.

5.1 Precommissioning procedure

a) The bearing housing must be filled with the

indicated oil. Check also the oil level.

b) The pump must be completely filled with liquid to

avoid running dry and to guarantee a correct

performance of the pump.

c) During filling the pump shall reach the specified

temperature, so pumps for hot liquids (T > 100 °C

(212 °F)) shall be warmed up by preflushing.

d) Check the sense of rotation of the pump (Coupling

spacer dismantled).

Sense of rotation is clockwise viewed to the drive

end of the pump.

e) The pump rotor and the shaft seal must be in

correct axial position. Mounting plates of

mechanical seal must be locked at the seal gland

in open position. Drive-collar of the mechanical

seal sleeve must be tightened.

f) Check the readiness of all auxiliary systems (seal

sys., lubrication sys.,...) for start up.

g) All pipe work, including the internal and the

auxiliary pipe work, must be connected correctly

and must be absolutely tight. Check the tightness

of all connections of the auxiliary pipe work. The

suction valve must be open, the discharge valve

shall be closed.

h) Turn the pump by hand, if required with the help of

a lever, to check the free rotation of the rotor. The

rotor must turn uniformly and noiselessly. Some

resistance may be felt due to friction in bearings

and seals.

i) Check the readiness of the driver for start up. Refer

to the manual of the driver (preheating for

explosion proof E-motor).

5.2 Pump Lubricants

5.2.1 Lubrication

The bearing housing shall be filled with proper

lubricating oil prior to start up. If the pump will be

started after a longer storage period, the bearing

housing should be first flushed and cleaned with

gasoline. It is not necessary to remove the