HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 21 of 39

5.2.8 Lubrication

The bearing housing shall be filled with proper

lubricating oil prior to start up. If the pump will be

started after a longer storage period, the bearing

housing should be first flushed and cleaned with

gasoline. It is not necessary to remove the

preservation oil as this will mix up thoroughly with the

lubrication oil.

Lubrication is provided by the pumping effect of the

rotating ball bearings. Maintaining the correct oil level

(middle of the oil sight glass) ensures that the lower

ball bearing is covered with oil.

For recommended lubricating oils refer to the

lubrication table 5.2.6

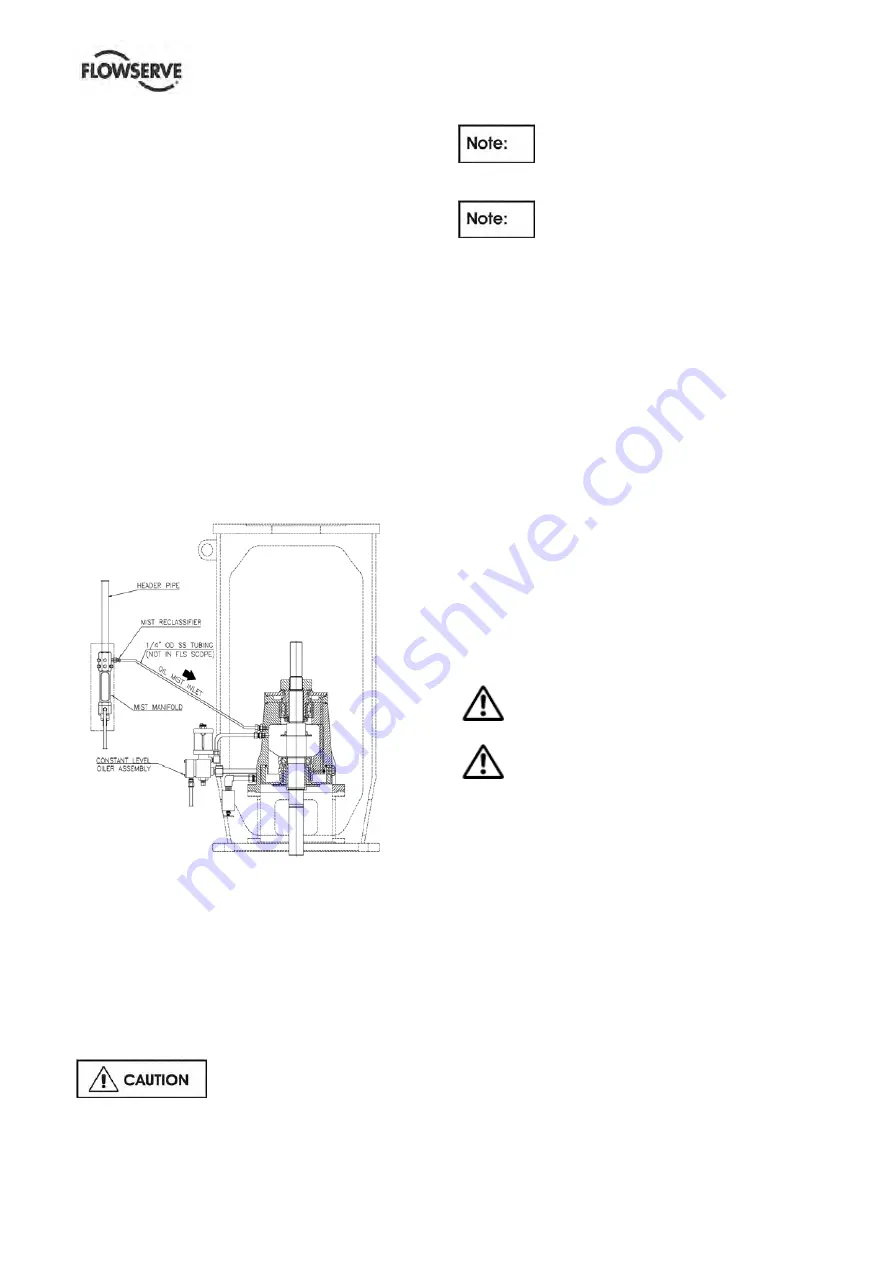

5.2.9 Purge oil mist Lubrication

Purge oil mist system utilize a continuous oil mist flow

through the bearing housing to deliver clean oil

directly to the bearing housing to maintain an outward

flow of air from the housing to prevent the ingress of

moisture and other corrosive contaminants.

The supplied air must be dry and clean. The

cleanness must be < 5µm.

For Purge Oil Mist Lubrication, a Reclassifier with a

Value of 0.09 SCFM should be used at the Manifold.

The bearing housing is equipped with a Purge Mist

Vent Fill Assembly at the top of the bearing housing

and with a constant level oiler with included overflow

device. The Overflow connection (3/8” tube) shall be

connected to a collection container.

Check overflow setting as per Oiler IOM.

The pressure in the bearing housing shall be 0,05

bar (0,74 psi) (20 inches of water column). A

continuous oil mist lubrication should be occur

during operation and stand by.

After start up the bearing temperature

must be observed carefully. The temperature at the

bearing housing should not exceed 85°C.

Refer to the GA-drawing regarding the

connections to the supply systems.

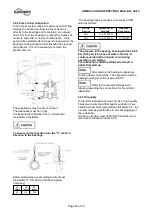

5.2.10 Oil change

After first start up, the oil shall be changed after 200

service hours.

Every further oil change shall take place after about

2000 service hours or at least every 6 month.

To change the oil use the following procedure:

f) Open the oil drain on the bearing housing to

remove the oil.

g) Close the oil drain and fill in Oil through the vent

connection on the bearing cover until the oil level

reaches the middle of the sight glass.

h) Fill the reservoir of the constant level oiler.

i) If necessary, the oil level can be adjusted by

referring to section 5.2.4

Oil level

.

5.2.11 Oil level

The correct oil level is in the middle of the oil sight glass

and shall be checked when pump is not in operation.

Periodically check if the lubricating oil is mixed with any

condensed water. Careful opening of the oil drain

during a stop of the pump will show any water.

During operation a small increase of the oil level

can occur due to the oil mist supply.

A too high oil level will result in higher bearing

temperatures and therefore poorer lubrication.

5.2.12 Oil quality

Oil used for lubrication should only be of high quality.

The viscosity of the oil at working temperature must

be at least 10 cSt. The pouring point of the oil must

be in accordance with the lowest expected

temperature of the bearing housing during a stop of

the pump. For recommended lubricating oils refer to

the lubrication table.

Having selected the corresponding oil quality the

actual oil temperature at the bearing housing must be

checked after two service hours of the pump.

Considering this measured oil temperature the actual

viscosity must be determined by using the data sheet

of the oil, to verify the minimum required viscosity of

10 cSt. Do not forget, the oil temperature in the

bearing itself is about 10 °C (∆18 °F) higher than the

oil

temperature at the bearing housing. On the

following

table the oil viscosity is given at 40 °C (104

°F). Determining the correct lubricating oil one must