HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 32 of 39

temperature may be observed during the run in

period.

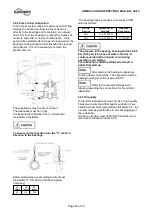

The faces of the inner mechanical seal are flushed by

the product (API Plan11). In Plan 11, product is

routed from the pump discharge via an orifice to the

seal chamber to provide cooling for the seal and to

vent air or vapors from the seal chamber. Fluid then

flows from the seal cavity back into the process

stream. Between the inner mechanical seal and the

outer (atmospheric) mechanical seal is a liquid buffer

fluid, which is unpressurized (API Plan 52). The

buffer fluid is contained in a seal pot (refer to drawing

of the seal pot), which is vented to a vent system,

thus maintaining the buffer fluid pressure close to

atmospheric.

Inner seal leakage will be product leakage into the

buffer fluid. There will always be some leakage

(max.5 ml/hour).

Plan 52 is used for flashing liquids, which have a

vapour pressure higher then the buffer fluid pressure.

So the product will flash in the seal pot and the

vapour can escape to the vent system.

All screw / flange connections have to be proofed.

Straight screw joints made of stainless steel have to be

tightened especially carefully.

Fill the seal system with a suitable

buffer fluid (refer to lubrication table).

Ensure that the valve GV for the

connection V is open (Barrier/buffer fluid vessel

drawing).

Open the Block & Bleed valve to

allow proper function of the PSH (set point 0.5 bar

(7.25 psi) above flare pressure).

Open all necessary valves in the

cooling and auxiliary piping and check the flow.

Disassembly of the seal cartridge

is only allowed by authorized personal. Contact

Flowserve for any service of the mechanical seal. We

recommend to have a spare cartridge seal on stock

for easy replacement.

7.1.4 Single Mechanical Seal with API–Plan 23+61

Refer to mechanical seal drawing and

auxiliary piping drawing.

The pump is equipped with a single mechanical seal.

The cartridge design allows to change the

mechanical seal without taking it apart.

Actions before first start up:

The pump will be delivered with correct vertical

adjustment of the rotor.

Try to turn the rotor by hand.If

the rotor cannot be turned readjust it following

procedure in section 5.3.1

Adjusting of the rotor.

The mechanical seal requires no adjustment

anymore. Check if the mounting plates are

alreadyswung out.

Actions after start up:

Check all connections to the seal gland and the

mechanical seal itself against leakage. It is usual that

at the seal faces a small leakage occurs after start

up, which decreases with the time of operation and

should stop after the seal is run in. Check the

temperature of the seal gland. I slight increase of

temperature may be observed during the run in

period. The mechanical seal is flushed by an API

Plan 23 and the temperature at the seal gland should

be below the pumped liquid temperature (refer to

mechanical seal drawing for temperature limit).

Plan 23 is the plan of choice for all hot water

services, and it is also disirable in many hydrocarbon

and chemical services where it is necessary to cool

the fluid establish the required margin between fluid

vapor pressure (at the seal chamber temperature)

and seal chamber pressure. In a Plan 23, the cooler

only removes seal face-generated heat plus heat

soak from the process. The seal chamber is isolated

by a pump throat bushing with a bypass to suction.

API Plan 61 has tapped and plugged connections for

the purchaser´s use. Typically this plan is used when

the purchaser is to provide fluid (such as steam, gas, or

water) to an external sealing device.

Refer to the GA - drawing for the

required quench medium, pressure and flow.

Disassembly of the seal cartridge

is only allowed by authorized personal. Contact

Flowserve for any service of the mechanical seal. We

recommend to have a spare cartridge seal on stock

for easy replacement.

7.1.5 Dual Mechanical Seal pressurized with

API–Plan 53b

Refer to mechanical seal drawing and

auxiliary piping drawing.

The pump is equipped with a dual mechanical seal in

face to back configuration, back to back configuration

or face to face configuration.