HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 6 of 39

party responsible for assembling the pump set shall

select the coupling, driver and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable for

the area in which it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so,

for pump sets with a VFD, the ATEX Certification for

the motor must state that it covers the situation where

electrical supply is from the VFD. This is particular

requirement still applies even if the VFD is in a safe

area.

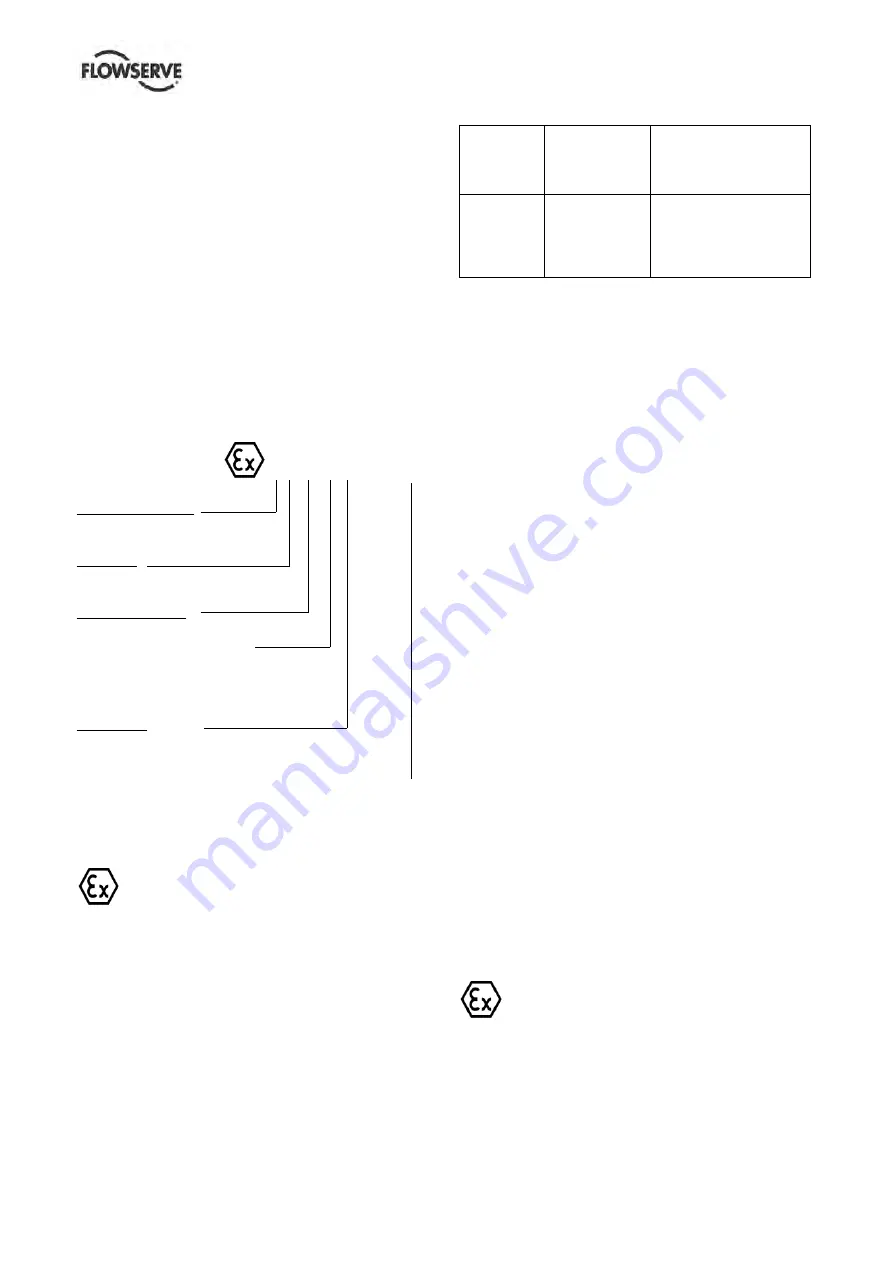

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC135ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = High level protection

3 = normal level of protection

Gas and/or Dust

G = Gas; D= Dust

c = Constructional safety

(in accordance with EN13463-5)

b = Control of ignition source

(in accordance with EN13463-6)

Gas Group

IIA – Propane (Typical)

IIB – Ethylene (Typical)

IIC – Hydrogen (Typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3)

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on an ambient in the range of -80 to +55 ºC (-112 to

+131 ºF); refer to Flowserve for ambient

temperatures outside this range for this product.

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

maximum permissible liquid temperature depends on

the ATEX temperature class and must not exceed the

values in the table that follows.

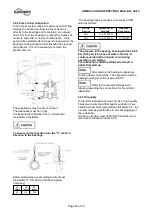

Temperature

class to

EN 13463-1

Maximum

surface

temperature

permitted

Temperature limit of liquid

handled (* depending on

material and construction

variant - check which is

lower)

T6

T5

T4

T3

T2

T1

85 °C (185 °F)

100 °C(212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

* The table only takes the ATEX temperature class into

consideration. Pump design or material, as well as component

design or material, may further limit the maximum working

temperature of the liquid.

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken into

account in the temperatures stated.

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and when the pump is

required to be used in differently classified potentially

explosive atmospheres. In this case the user is

responsible for ensuring that the pump surface

temperature does not exceed that permitted in its

actual installed location.

Do not attempt to check the direction of rotation with

the coupling element/pins fitted due to the risk of

severe contact between rotating and stationary

components.

Where there is any risk of the pump being run against

a closed valve generating high liquid and casing

external surface temperatures it is recommended that

users fit an external surface temperature protection

device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips or a Power Monitor and

make routine vibration monitoring.

In dirty or dusty environments, regular checks must

be made and dirt removed from areas around close

clearances, bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal