HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 30 of 39

duration of service, all roller bearings should be

renewed, too.

6.9 Assembly

To assemble the pump consult the sectional

drawings.

Ensure threads, gasket and O-ring mating faces are

clean. Apply thread sealant to non-face sealing pipe

thread fittings.

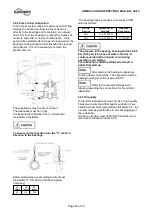

6.9.1 Assembly of the hydraulic cartridge

1) Mount the mechanical seal to the casing cover

[1221]. Tight hex nuts [6581.4] of studs [6572.4].

Insert O-ring [4610.4] into

casing cover [1221].

2) Insert the O-ring [4610.3] into the liner [1649] and

slip it on to the shaft.

3) Put in the key [6700.1] and slip on the 2

nd

stage

impeller [2200]. Now put on the interstage plate

[1471] including the bushing [3300}.

If applicable, secure the

bushing [3300] with the set screw.

Insert O-rings

[4610.2,4610.5] into the interstage plate [1471].

Tight the socket head cap screws [6579.1] to fix

the assembly.

4) Slip on the bearing sleeve [3400] and the first

stage impeller [2200] and the lockwasher

[6541.1].Tight the assembly with the impeller nut

[2912] and secure it with the lockwasher [6541.1].

If the pump is equipped with an

inducer [2215], it replaces the shaft nut.

5) Now the complete motor hydraulic assembly can

be put into the casing. Tight hex nuts [6581.2] of

the studs [6572.2].

Take care of pin [6811] to

ensure correct position of the motor hydraulic

assembly in the casing.

6.9.2 Assembly of the bearing housing

1) Push radial ball bearing [3011] to the shaft

[2100].

Heat up the bearing with an

applicable device to 110°C.

2) Mount the pair of thrust ball bearing [3013] to the

bearing adaptor sleeve [2471] by turning the

bearing lock nut [3712].

Install the lockwasher

[6541.2].

3) Install the oil ring [3861] and secure it with the

grub screw [6814.3].

4) Put in key [6700.3] and slip the thrust bearing

assembly to the shaft [2100].

5) Put in the key [6700.2] and mount the pumping

ring [4223] at the line bearing side.

Take care of the O-ring

[4610.7].

6) Now you can push the shaft assembly into the

bearing housing [3200].

7) Mount the distance sleeve [2460] and the

deflector [2540]. Secure the deflector with the

grub screw [6814.2].

If grease catcher [3865] have been

disassembled, it must be installed before

mounting the deflector [2540]. Take care of the

O-ring [4610.6].

8) Put on the cover [3260] and [1220] and tight the

hexagon head bolt [6577.4].

Take care of the O-rings

[472] and the labyrinth ring [4330].

9) Install stuffing box housing [4110].

10) Mount shaft nut [2910] and set rotor clearance

according to chapter

5.3.1 Adjusting of the rotor

.

6.9.3 Assembly of shaft seal

1) Replacing the mechanical seal extreme cleanness

is recommended. The sealing faces of the

mechanical seal must be free of scratches or other

damages and must be cleaned once again before

assembly.

2) Before sliding the rotating parts on the shaft

respectively on the shaft sleeve, the fits must be

sufficiently lubricated with a molykote paste.

Take care that the sealing faces

remain clean and no grease touches them.

3) If a mechanical seal with pump ring for medium

circulation is used pay attention to the rotation of

pump and pump ring.

4) At assembling the seal end plate [4212] pay

attention to the position of piping connections for

injection or quench (refer to shaft seal drawing).

5) For assembly of shaft seal use the reverse

procedure as described in the chapter

„Disassembly of shaft seal“ before. Important is

the fixing of the mechanical seal by the tools. So

a damage of the mechanical seal during further

assembling can be avoided.

Before start up the tools must

absolute turned out of the groove of the shaft