IJ PUMP OPERATION AND MAINTENANCE MANUAL

BO2660-01 xiv

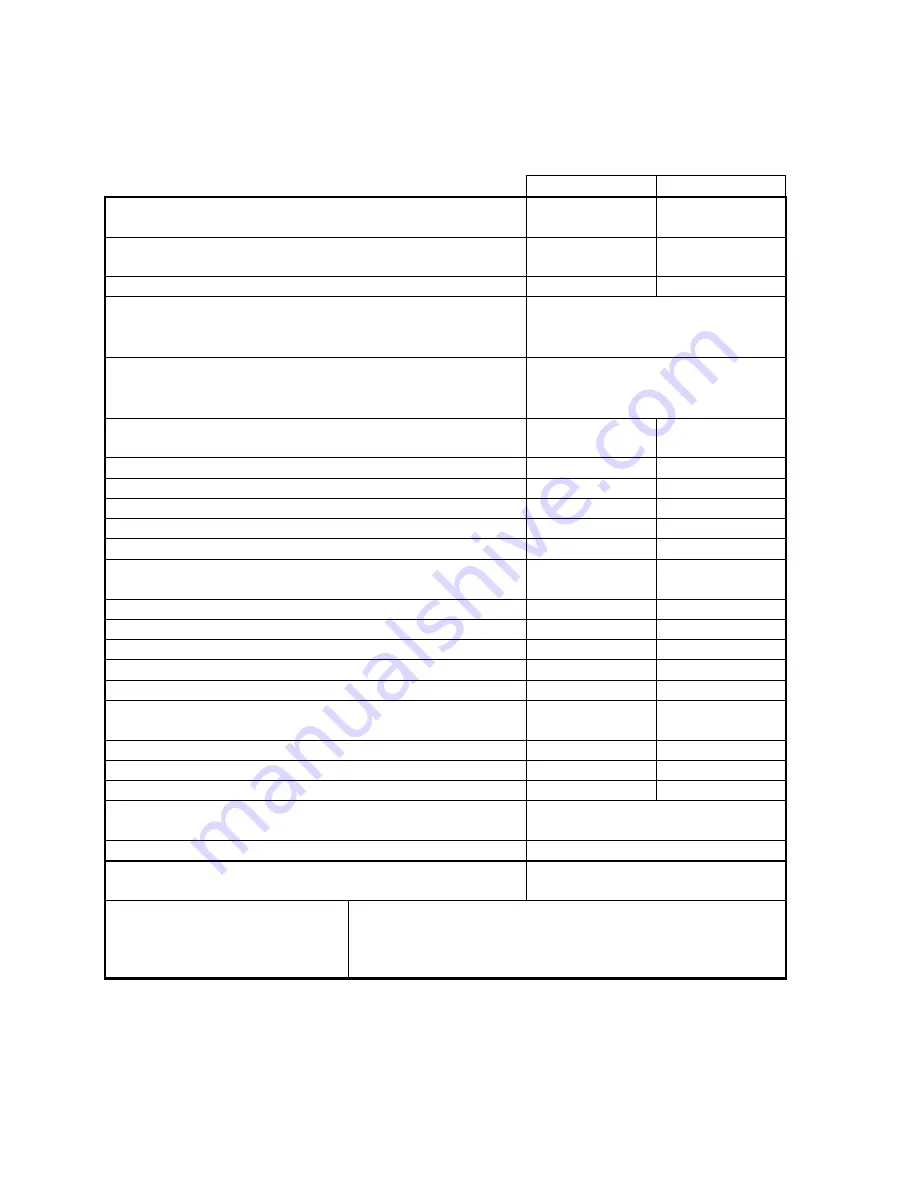

OPERATING SPECIFICATIONS

PUMP SERIAL NUMBER BXXXXX-01

(CONTINUED)

English

Metric

Part-to-Part fits

Inch, F

mm, C

Suction spacer, intermediate cover, discharge cover

interference

fit

0

0

.00

.00

Head-to-case gap shall be parallel all around within

.002

.05

Head-to-case nut torque procedure

See procedure in this section.

Pump Foot Holddown Bolt torque procedure

See procedure in this section.

Part removal heat, maximum

F

C

Impeller

600

316

Pressure reducing sleeve

600

316

Destaging spacer, impeller spacer sleeve

185

85

Thrust collar

450

232

Suction spacer, intermediate cover, discharge spacer

140

60

Part installation heat, maximum

F

C

Impeller

350

177

Pressure reducing sleeve

350

177

Destaging spacer, impeller spacer sleeve

160

71

Thrust collar

300

149

Suction spacer, intermediate cover, discharge spacer

140

60

Warm-up temperatures

F

C

Recommended warm-up rate, degrees per hour

50 to 75

28 to 42

Maximum differential between top and bottom of case

75

42

Maximum differential between lowest case and stream

180

100

Lube Oil System Requirements

System type:

Pressure feed

Alarm and Trip Setpoint Temperatures:

See lube oil system drawings in the

back of this manual.

Lube Oil Specifications:

High grade turbine type mineral oil, viscosity ISO VG 32. Rust,

oxidation, and foam inhibited. No free acid, chlorine, or

sulfur. No more than a trace of free alkali. Must be

compatible with all parts lubricated by the same system.

Summary of Contents for IJ

Page 2: ...IJ PUMP INSTALLATION OPERATION MAINTENANCE ...

Page 3: ......

Page 5: ...IJ PUMP OPERATION AND MAINTENANCE MANUAL BO2660 01 iv ...

Page 11: ...IJ PUMP OPERATION AND MAINTENANCE MANUAL BO2660 01 x ...

Page 13: ...IJ PUMP OPERATION AND MAINTENANCE MANUAL BO2660 01 xii ...

Page 17: ...IJ PUMP OPERATION AND MAINTENANCE MANUAL BO2660 01 xvi ...

Page 25: ......

Page 35: ...IJ PUMP OPERATION AND MAINTENANCE MANUAL BO2660 01 2 10 Figure 2 1 Foundation Bolt ...

Page 65: ......

Page 79: ......

Page 83: ......