flowserve.com

12 Logi

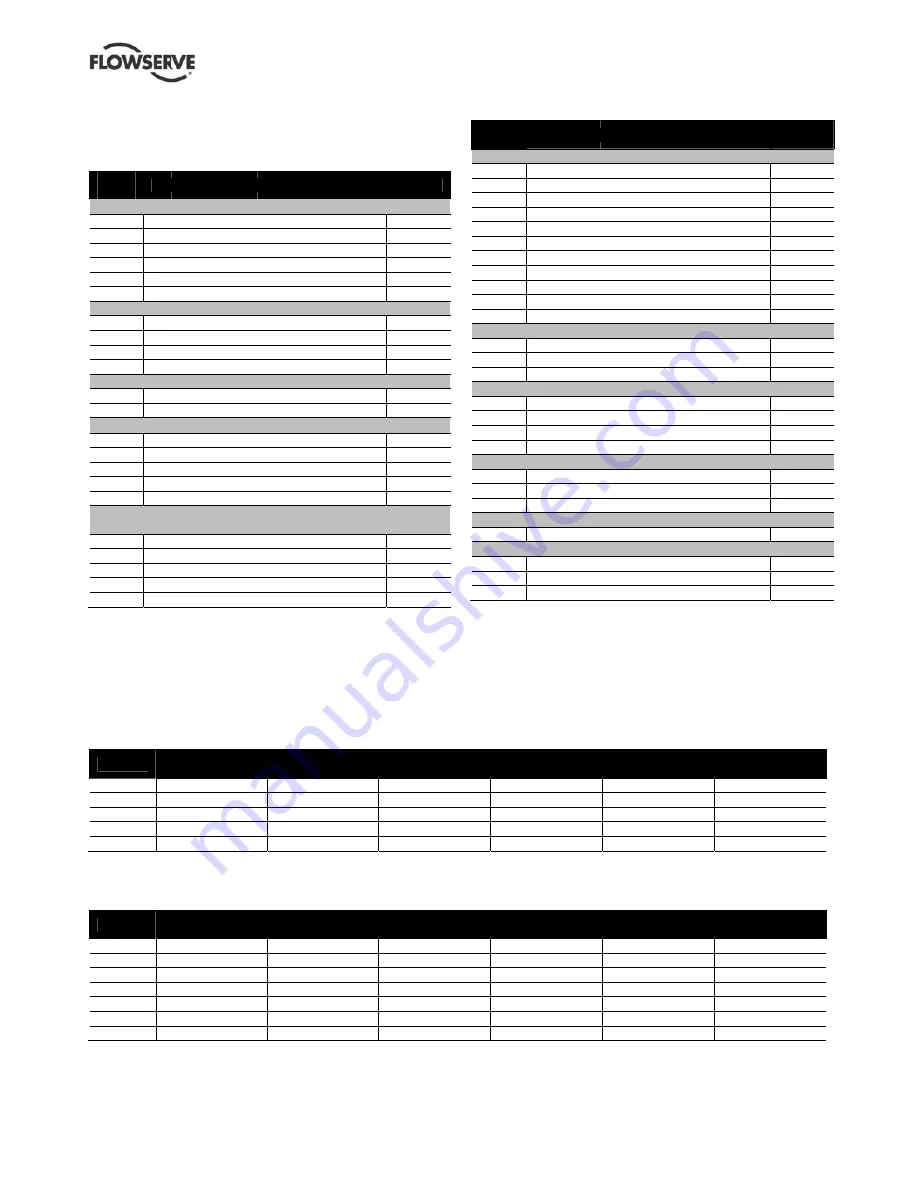

See figure 24

Item

No.

Des

Kit 2: Driver Mod

16 Pres

17 Scre

33 Driv

34 Hex

36 Scre

37 Nylo

Kit 3: Spool As

38 Spo

39 Spo

40 Scre

41 O-ri

Kit 4: Pressure

16 Pres

17 Scre

Kit 5: Feedback S

52 Fee

53 Scre

54 O-ri

55 Tors

56 E-rin

Kit 6: Feedback

(For ATEX inst

52 Fee

53 Scre

54 O-ri

55 Tors

56 E-rin

13 Logi

13.1 Valte

Table IX: Valte

Spud

2.00

2.62

2.88

3.38

4.75

* A 50 in.

2

, 2.00

** Live-loading i

Table X: Valto

Spud

0.44

0.63

0.75

0.88

1.12

1.50

1.75

* Standard: all r

Optional: all rota

x 3200MD

for item numbe

scription

ule Assembly -40 °

ssure Regulator

ew, Regulator to

ver Module Assem

x Barbed Fitting w

ew, Driver to Hou

on Washer

sembly Valve Ki

ool

ool Valve Block

ew, Spool Valve

ng, Spool Valve

Regulator, P/N

ssure Regulator

ew, Regulator to

Shaft Kit, P/N 1997

dback Shaft

ew, Spring to Fee

ng, Feedback Sh

sion Spring

ng

k Shaft Kit (NAM

tallation only)

dback Shaft

ew, Spring to Fee

ng, Feedback Sh

sion Spring

ng

x 3200MD

ek Mounting

ek Linear Moun

25

Standard

164432

0 spud with live l

is not available o

ork Rotary Mou

25

Standard

135429

135429

135429

135429

135429

135429

135429

rotary valves with

ary valves with h

D Spare P

ers.

° to 80 °C Kit, P/N

Housing

mbly

w

⁄

Captive O-ring

using

t, P/N 199787.99

to Housing

215814.999.000

with Captive O-r

Housing

88.999.000 (For AT

edback Shaft

haft

MUR), P/N 21881

edback Shaft

haft

D Mountin

g Kits

nting Kits

5 in.

2

Handwhe

164433

loading requires

on a 100 in.

2

, 2.6

unting Kits *

5 in.

2

Optiona

135432

135437

135438

135439

h standard acces

handwheels or vo

Use

Parts Kits

Quanti

199786.999.000

1

4

1

g 1

1

1

99.000

1

1

2

3

rings 1

4

TEX installation on

1

1

1

1

1

4.999.000

1

1

1

1

1

ng Kits

eel

Stan

164

164

kit number.

2 spud.

al

Stan

135

135

135

135

135

135

135

ssories (end of sh

olume tanks (link

er instructions

ity

ly)

Item

No.

Kit 7: So

3

15

20

22

26

35

37

41

45

46

54

Kit 8: P

11

13

15

Kit 9: M

6

7

Kit 10: U

24

25

26

Kit 11: A

10

Kit 12: P

49

50

51

50 in.

2

*

ndard

4434

4435

50 in.

2

*

ndard

5430

5430

5430

5430

5430

5430

5430

haft mount).

kage design).

– Digital Positi

Description

oft Goods Kit, P/

O-ring, Main

O-ring, Press

O-ring, Regu

O-ring, Custo

O-ring, Custo

Flexible Tube

Nylon Washe

O-ring, Spoo

Hydrophobic

O-ring, Spoo

O-ring, Feed

ressure Sensor B

Screw, Press

Pressure Se

O-ring, Press

Main PCB Assem

Screw, Main

Screw, Main

Main PCB

Screw, Main

User Interface Bo

Screw, Custo

Customer Int

O-ring, Custo

Analog Output B

Analog Outp

Position Feedbac

Screw, Feedb

Metal Washe

Position Fee

Handwheel

164433

164436

Optional

135433

137212

137213

137214

ioner 3200MD

/N 199789.999.0

Housing Cover

sure Sensor to H

ulator to Housing

omer Interface C

omer Interface B

e

er

ol Valve to Housi

c Filter, Spool Va

ol Valve Cover

dback Shaft

Board Kit, P/N 19

sure Sensor Boa

nsor Board

sure Sensor to H

bly Kit, P/N 2550

PCB Cover Sho

PCB Cover Lon

PCB Retaining

oard Kit, P/N 199

omer Interface to

terface Board

omer Interface B

Board Kit, P/N 22

put Board

ck Potentiomete

back Potentiomet

er

edback Potentiom

10

Standard

164437 **

164437

164439

164439

10

Standard

135431

135431

135431

135431

135431

135431

135431

LGENIM0059

000

Housing

g

Cover

Board

ng

alve Chamber

99791.999.000

ard

Housing

014.999.000

ort

ng

Screw

9793.999.000

o Housing

Board

6527.999

r Kit, P/N 199794

ter to Housing

meter

00 - 200 in.

2

Handw

1644

1644

1644

1644

00 - 200 in.

2

Optio

1354

1372

1372

1372

9-04 09/11

35

Quantity

1

2

1

1

1

1

1

3

1

1

1

2

1

2

2

1

1

1

3

1

1

1

4.999.000

2

2

1

wheel

436

438

440

440

onal

434

215

216

217