MPT USER INSTRUCTIONS ENGLISH 85392699 06-09

20 of 41

®

6 MAINTENANCE

6.1 Maintenance schedule

Our specialist service personnel can help with

preventative maintenance records and provide

condition monitoring for temperature and vibration

to identify the onset of potential problems if

required. This schedule is a recommendation only

and is intended to be amended by site experience

of the prevailing conditions. It outlines

recommendations for the pump only and must be

supplemented by schedules for other equipment on

the package.

6.1.1 Routine inspection (daily/weekly)

The following checks should be made and the

appropriate action taken to remedy any deviations:

•

Check operating behavior. Ensure performance,

noise, vibration, and bearing temperatures are

normal

•

Check that there is no abnormal fluid or

lubricant leakage

•

Check running hours since last oil change.

Change if required

•

Refer to the manuals of any associated

equipment for routine checks needed

•

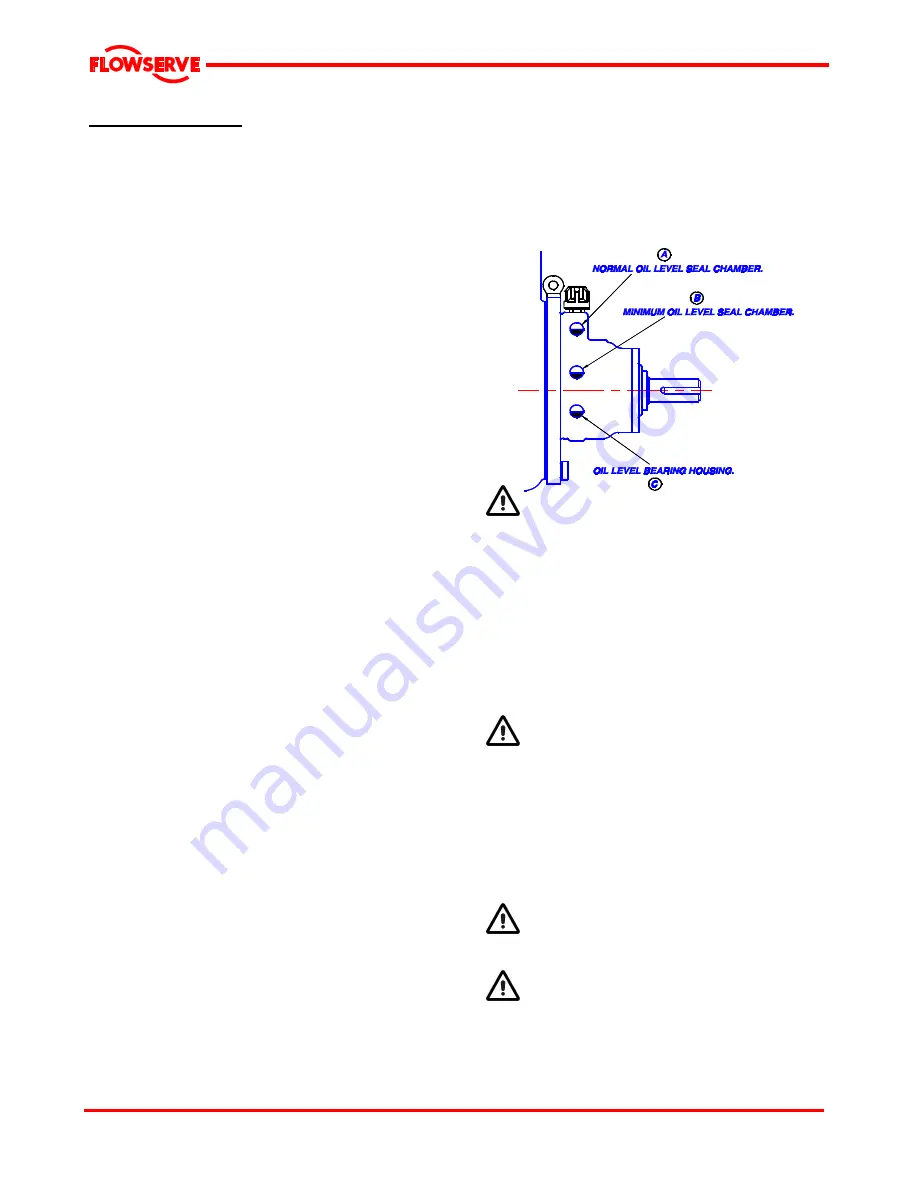

Check oil levels in seal chamber and bearing

housing

6.1.2 Periodic inspection (6 monthly)

•

Check foundation bolts for security of

attachment and corrosion

•

The coupling should be checked for correct

alignment and worn driving elements

•

Check all paint or protective coatings

•

Check all cable glands for tightness

•

Refer to the manuals of any associated

equipment for periodic checks needed

6.2 Lubrication data

6.2.1 Oil lubricated bearings and

mechanical seals

Normal intervals between oil changes are 4000

operating hours or a 12-month period. The

characteristics of the installation and severity of

service will determine the frequency of lubrication

change. See Section 3.3.4, Pump lubricant data.

Any sudden change in oil level should be

investigated without delay. A rise in bearing

housing oil level, together with a drop in the seal

chamber oil level, indicates a secondary seal failure

allowing oil leakage from the seal chamber to the

bearing housing. A drop in bearing housing oil level

indicates an external leak and a check of the pump

would show the source as a failure of the bearing

cover lip seal or gasket or a loose drain plug. An

abnormal rise or fall in the seal chamber oil level

with no change in the bearing housing oil level

indicates a primary seal failure with product leaking

into seal chamber or oil leaking into the pump.

Always use the recommended Type and

grade of oil, Mobil DTE Medium or Castrol Hyspin

AWS 46. Never mix oil types.

6.3 Mechanical seals

When leakage becomes unacceptable as

determined above, the seal will need to be repaired

or replaced.

6.4 Dismantling

6.4.1 General

Cleanliness is extremely important and care

must be taken to prevent any foreign material from

entering the pump or its components.

This pump is of the back pull-out design; it is not

necessary to remove the casing, to detach the

suction and delivery piping, or to remove the driver

to dismantle pump.

6.4.2 Dismantling the pump

Refer to Safety section before dismantling

the pump.

6.4.3 Genuine Flowserve parts

Before dismantling the pump for overhaul,

ensure genuine Flowserve replacement parts

are available.

Summary of Contents for MPT 20

Page 24: ...MPT USER INSTRUCTIONS ENGLISH 85392699 06 09 24 of 41 Page left intentionally blank ...

Page 38: ...MPT USER INSTRUCTIONS ENGLISH 85392699 06 09 38 of 41 NOTES ...

Page 39: ...MPT USER INSTRUCTIONS ENGLISH 85392699 06 09 39 of 41 NOTES ...

Page 40: ...MPT USER INSTRUCTIONS ENGLISH 85392699 06 09 40 of 41 NOTES ...