USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 18 of 52

flowserve.com

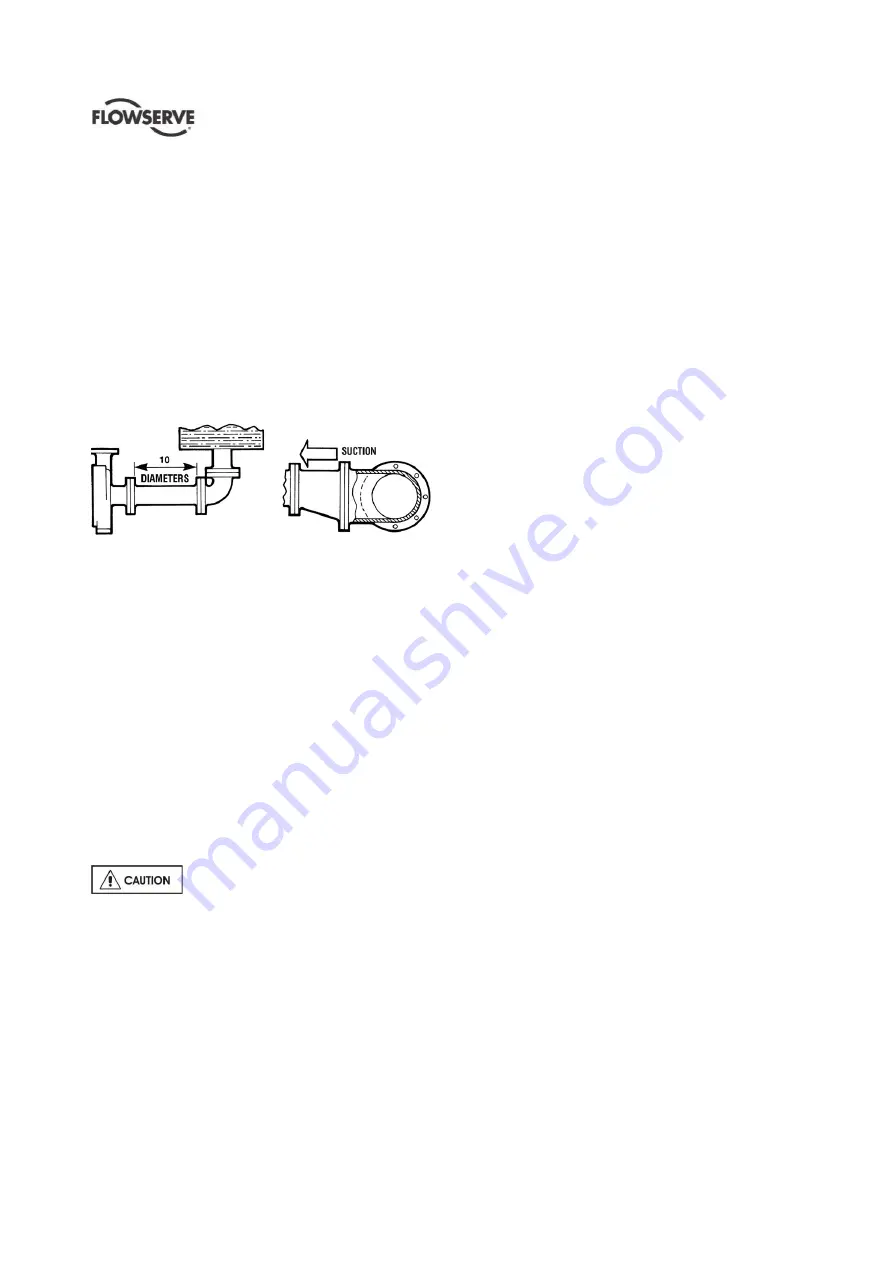

Figure 4-7 illustrates the ideal piping configuration

with a minimum of 10 pipe diameters between the

source and the pump suction. In most cases,

horizontal reducers should be eccentric and mounted

with the flat side up as shown in figure 4-8 with a

maximum of one pipe size reduction. Never mount

eccentric reducers with the flat side down.

Horizontally mounted concentric reducers should not

be used if there is any possibility of entrained air in

the process fluid. Vertically mounted concentric

reducers are acceptable. In applications where the

fluid is completely de-aerated and free of any vapor

or suspended solids, concentric reducers are

preferable to eccentric reducers

Figure 4-7 Figure 4-8

Avoid the use of throttling valves and strainers in the

suction line. Start up strainers must be removed

shortly before start up. When the pump is installed

below the source of supply, a valve should be

installed in the suction line to isolate the pump and

permit pump inspection and maintenance. However,

never place a valve directly on the suction nozzle of

the pump.

Refer to the Durco Pump Engineering Manual and

the Centrifugal Pump IOM section of the Hydraulic

Institute Standards for additional recommendations

on suction piping, section 10. Refer to section 3.4 for

performance and operating limits.

4.6.3 Discharge piping

Install a valve in the discharge line. This valve is

required for regulating flow and or to isolate the pump

for inspection and maintenance.

When fluid velocity in the pipe is high,

for example, 3 m/s (10 ft/sec) or higher, a rapidly

closing discharge valve can cause a damaging

pressure surge. A dampening arrangement should

be provided in the piping.

A non-return valve should be located in the discharge

pipework to protect the pump from excessive back

pressure and hence reverse rotation when the unit is

stopped.

4.6.4 Allowable nozzle loads - PolyChem GRP

pumps (ASME B73.5)

Flowserve chemical process pumps meet or exceed

the allowable nozzle loads given by ANSI/HI 9.6.2.

The following paragraphs describe how to calculate

the allowable loads for each pump type and how to

determine if the applied loads are acceptable.

The following steps are based upon ANSI/HI 9.6.2.

All information necessary to complete the evaluation

is given below. For complete details please review

the standard.

a)

Find the “Baseplate

Correction Factor” in

figure

4-10. The correction factor depends upon how

the baseplate is to be installed

b) The casing material correction factor for the GRP

material is 0.9.

c) Select the lowest correction factor from steps a)

and b). For example:

If the pump is mounted on a Type A grouted

baseplate, the correction factor used is 0.9.

If the pump is mounted on a Type D stilt

mounted baseplate, the correction factor is 0.75.

d) Locate the pump model being evaluated in

figures 4-12 through 4-15 and multiply each load

rating by the lowest correction factor. Record the

adjusted loads for each table.

e) Calculate the applied loads at the casing flanges

according to the coordinate system depicted in

figure 4-9. The 12 forces and moments possible

are Fxs, Fys, Fzs, Mxs, Mys, Mzs, Fxd, Fyd, Fzd,

Mxd, Myd and Mzd. For example, Fxd

designates Force in the “x” direction on the

discharge flange. Mys designates the Moment

about the “y”

-axis on the suction flange.

f) Figure 4-11 gives the acceptance criteria

equations. For long coupled pumps, equation

sets 1 through 5 must be satisfied.

g)

Equation set 1

. Each applied load is divided by

the corresponding adjusted figure 4-12 value.

The absolute value of each ratio must be less

than or equal to one.

h)

Equation set 2

. The summation of the absolute

values of each ratio must be less than or equal to

two. The ratios are the applied load divided by

the adjusted figure 4-13 values.

i)

Equation sets 3 and 4

. These equations are

checking for coupling misalignment due to nozzle

loading in each axis. Each applied load is divided

by the corresponding adjusted load from figure 4-14

and 4-15. The result of each equation must be

between one and negative one.

j)

Equation set 5

. This equation calculates the total

shaft movement from the results of equations 3 and

4. The result must be less than or equal to one.