USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 22 of 52

flowserve.com

Single seals requiring re-circulation will normally be

provided with the auxiliary piping from the pump

casing already fitted.

Seal housings/covers having an auxiliary quench

connection require connection to a suitable source of

liquid flow, low pressure steam or static pressure from a

header tank. Recommended pressure is 0.35 bar

(5 psi) or less. Check

General arrangement drawing

.

Double seals require a barrier liquid between the

seals, compatible with the pumped liquid.

With back-to-back double seals, the barrier liquid

should be at a minimum pressure of 1 bar above the

maximum pressure on the pump side of the inner

seal. The barrier liquid pressure must not exceed

limitations of the seal on the atmospheric side. For

toxic service the barrier liquid supply and discharge

must be in a safe area.

Special seals may require modification to auxiliary

piping described above. Consult Flowserve if unsure

of correct method or arrangement.

For pumping hot liquids, to avoid seal damage, it is

recommended that any external flush/cooling supply

be continued after stopping the pump.

Tandem seals require a barrier liquid between the

seals compatible with the pumped liquid.

4.6.6.2 Packing

When the pump is intended to be equipped with shaft

packing, it is not Flowserve standard practice to

install the packing in the stuffing box prior to

shipment. The packing is shipped with the pump. It

is the pump installer’s responsibility to install the

packing in the stuffing box.

Failure to ensure that packing is

installed may result in serious leakage of the pumped

fluid.

4.6.6.3 Piping connection

–

seal/packing support

system

If the pump has a seal support system

it is mandatory that this system be fully installed and

operational before the pump is started.

Packing lubrication

. Water, when compatible with the

pumpage, should be introduced into the seal gland at

pressure 0.69 to 1.03 bar (10 to 15 psi) above the

stuffing box pressure.

The gland should be adjusted to give a flow rate of 20

to 30 drops per minute for clean fluid. For abrasive

applications, the regulated flow rate should be 0.22 to

0.47 m

3

/h (1 to 2 US gpm)

Grease lubrication, when compatible with the liquid

being pumped, may be used. In non-abrasive

applications the liquid being pumped may be

sufficient to lubricate the packing without the need for

external lines.

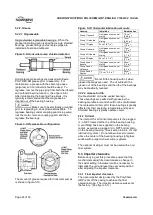

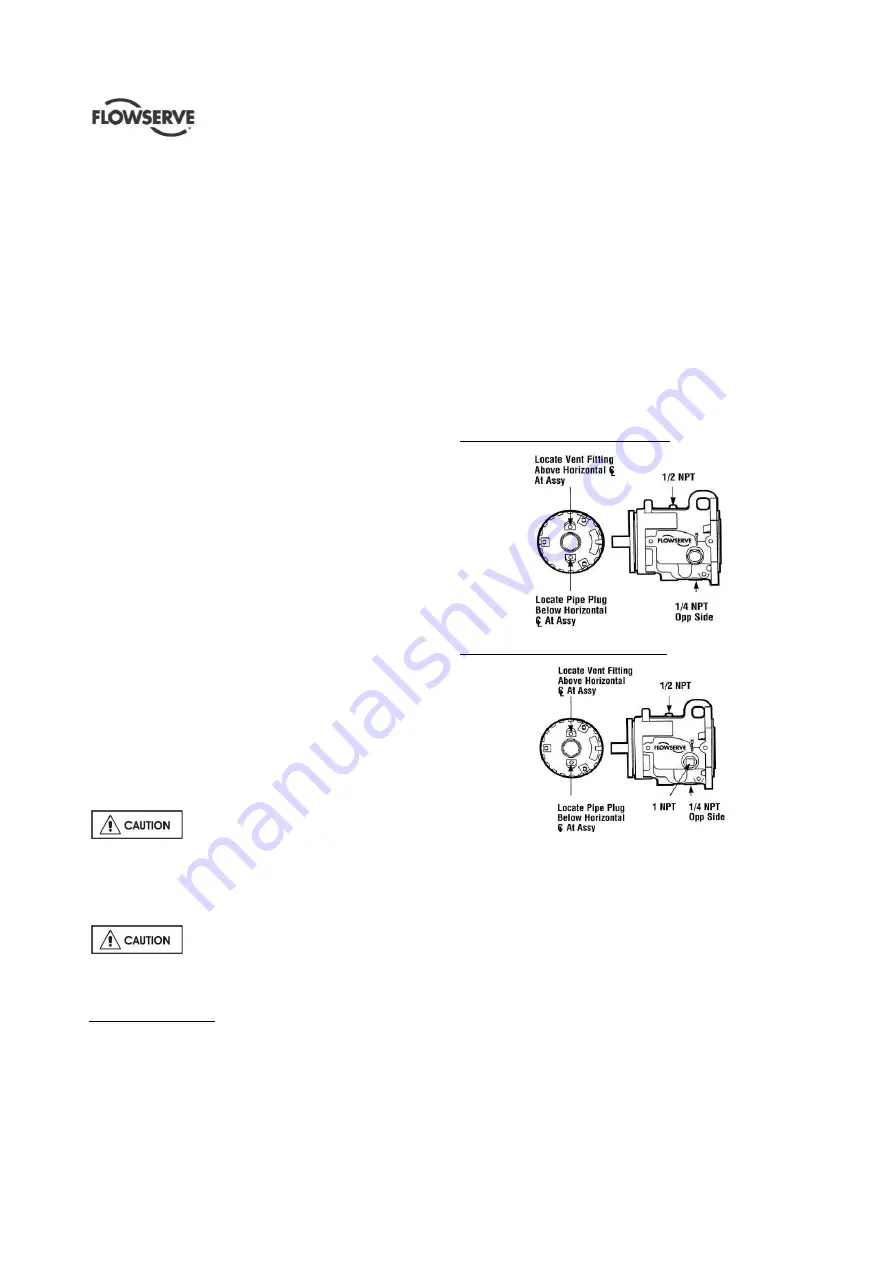

4.6.6.4 Piping connection - Oil mist lubrication

system

The piping connections for an oil mist lubrication

system are shown below.

Oil mist ready housing wet sump

Oil mist ready housing dry sump

4.6.6.5 Piping connection

–

air bleed line

The 1K3x2GS-7 self-priming pump evacuates the air

from the suction line when it primes. The length of

the line and diameter determine the volume of air and

the time required for priming. Flowserve

recommends that a small air bleed line be fitted from

the discharge piping to the sump if the air is not able

to freely vent out the discharge pipe.