USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 23 of 52

flowserve.com

4.7 Electrical connections

Electrical connections must be made

by a qualified Electrician in accordance with relevant

local national and international regulations.

It is important to be aware of the EUROPEAN

DIRECTIVE on potentially explosive areas where

compliance with IEC60079-14 is an additional

requirement for making electrical connections.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used during

wiring/installation do not increase electromagnetic

emissions or decrease the electromagnetic immunity of

the equipment, wiring or any connected devices. If in

any doubt contact Flowserve for advice.

The motor must be wired up in

accordance with the motor manufacturer's

instructions (normally supplied within the terminal

box) including any temperature, earth leakage,

current and other protective devices as appropriate.

The identification nameplate should be checked to

ensure the power supply is appropriate.

A device to provide emergency stopping must

be fitted.

If not supplied pre-wired to the pump unit, the

controller/starter electrical details will also be supplied

within the controller/starter.

See section 5.4,

Direction of rotation

before connecting the motor to the electrical supply.

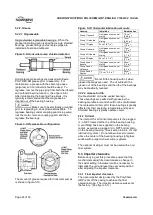

4.8 Final shaft alignment check

a) Level baseplate if appropriate.

b) Mount and level pump if appropriate. Level the

pump by putting a level on the discharge flange.

If not level, adjust the footpiece by adding or

deleting shims from between the footpiece and

the bearing housing.

c) Check initial alignment. If pump and driver have

been remounted or the specifications given below

are not met, perform an initial alignment as

described in section 4.5. This ensures there will

be sufficient clearance between the motor hold

down bolts and motor foot holes to move the

motor into final alignment. The pump and driver

should be within 0.38 mm (0.015 in.) FIM (Full

Indicator Movement) parallel, and 0.0025 mm/mm

(0.0025 in./in.) FIM angular.

Stilt mounted baseplates

. If initial alignment

cannot be achieved with the motor fasteners

centered, the baseplate may be twisted. Slightly

adjust (one turn of the adjusting nut) the stilts at

the driver end of the baseplate and check for

alignment to the above tolerances. Repeat as

necessary while maintaining a level condition as

measured from the pump discharge flange.

d) Run piping to the suction and discharge to the

pump. There should be no piping loads

transmitted to the pump after connection is made.

Recheck the alignment to verify that there are no

significant changes.

e) Perform final alignment. Check for soft-foot under

the driver. An indicator placed on the coupling,

reading in the vertical direction, should not indicate

more than 0.05 mm (0.002 in.) movement when

any driver fastener is loosened. Align the driver

first in the vertical direction by shimming

underneath its feet. When satisfactory alignment

is obtained the number of shims in the pack should

be minimized. It is recommended that no more

than five shims be used under any foot. Final

horizontal alignment is made by moving the driver.

Maximum pump reliability is obtained by having

near perfect alignment. Flowserve recommends

no more than 0.05 mm (0.002 in.) parallel, and

0.0005 mm/mm (0.0005 in./in.) angular

misalignment. (See section 6.8.4.7).

f)

The pump and motor will normally

have to be aligned at ambient temperature with

an allowance for thermal expansion at operating

temperature. (See chart below) In pump

installations involving high liquid temperatures,

the unit should be run at the actual operating

temperature, shut down and the alignment

checked immediately. See chart below for

recommended offset:

Pumped fluid temperature

Set the driver shaft

Up to 93 °C (200 °F)

Equal to the pump shaft

93 °C to 121 °C

(200 °F to 250 °F)

0.13 mm (0.005 in.)

below pump shaft

4.9 Protection systems

The following protection systems are

recommended particularly if the pump is installed in a

potentially explosive area or is handling a hazardous

liquid. If in any doubt consult Flowserve.

If there is any possibility of the system allowing the

pump to run against a closed valve or below

minimum continuous safe flow a protection device

should be installed to ensure the temperature of the

liquid does not rise to an unsafe level.