USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 26 of 52

flowserve.com

5.2.2 Grease

5.2.2.1 Regreasable

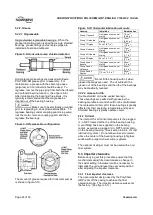

Single shielded regreasable bearings.

When the

grease lubrication option is specified, single shielded

bearings, grease fittings and vent pipe plugs are

installed inboard and outboard.

Figure 5-8: Horizontal pump shield orientation

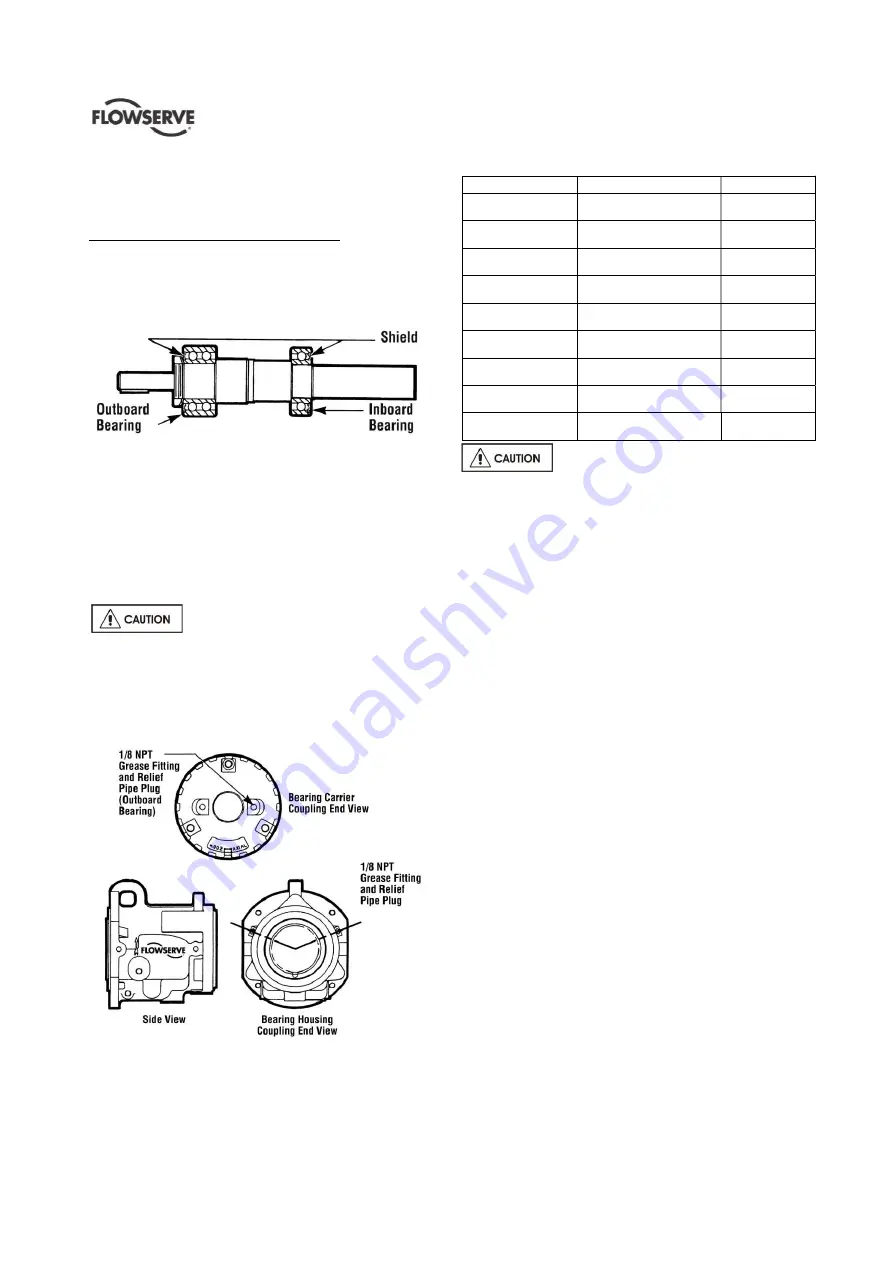

Horizontal pump bearings are packed with Exxon

POLYREX EM grease prior to assembly. For

relubrication, a grease with the same type base

(polyurea) and oil (mineral) should be used. To

regrease, remove the pipe plug from both the inboard

and outboard bearing location. (See figure 5-9.)

After relubricating the bearings three times, it is

typically recommended that the old grease be

cleaned out of the bearing housing.

Make sure to be electrically grounded

prior to regreasing in an explosive atmosphere. To

regrease bearings under coupling guard, stop pump,

lock the motor, remove coupling guard, and then

regrease the bearings.

Figure 5-9: Regreasable configuration

The amount of grease required for horizontal pumps

is shown in figure 5-10.

Figure 5-10: Horizontal lubrication amounts

Housing

Initial lube

Relubrication

Group 1 Inboard

Until grease comes out

of plug

7.5 cm

3

(0.46 in.

3

)

Group 1 Outboard

Until grease comes out

of plug

14 cm

3

(0.85 in.

3

)

Group 1 Duplex

34 cm

3

(2.1 in

3

)

17 cm

3

(1.0 in.

3

)

Group 2 Inboard

Until grease comes out

of plug

17 cm

3

(1.0 in.

3

)

Group 2 Outboard

Until grease comes out

of plug

28 cm

3

(1.7 in.

3

)

Group 2 Duplex

68 cm

3

(4.1 in

3

)

34 cm

3

(2.1 in.

3

)

Group 3 and 4

Inboard

Until grease comes out

of plug

30 cm

3

(1.8 in.

3

)

Group 3 and 4

Outboard

Until grease comes out

of plug

54 cm

3

(3.3 in.

3

)

Group 3 and 4

Duplex

115 cm

3

(7.0 in.

3

)

60 cm

3

(3.7 in.

3

)

Do not fill the housing with oil when

greased bearings are used. The oil will leach the

grease out of the bearings and the life of the bearings

may be drastically reduced.

5.2.2.2 Grease for life

Double shielded or double sealed bearings

These bearings are packed with grease by the

bearing manufacturer and should not be relubricated.

The replacement interval for these bearings is greatly

affected by their operating temperature and speed.

Shielded bearings typically operate cooler.

5.2.3 Oil mist

The inlet port for all horizontal pumps is the plugged

½ in. NPT located at the top of the bearing housing.

A vent fitting has been supplied on the bearing

carrier, as well as a plugged ¼ in. NPT bottom drain

on the bearing housing. (See section 4.6.6.4,

Oil mist

lubrication system.

) Do not allow oil level to remain

above the center of the bearing housing sight glass

window with purge mist (wet sump) systems.

The optional oil slinger must not be used with an oil

mist system.

5.3 Impeller clearance

Before carrying out this procedure ensure that the

mechanical seal(s) fitted can tolerate a change in

their axial setting, otherwise it will be necessary to

dismantle the unit and reset the seal axial position

after adjusting the impeller clearance.

5.3.1 Final impeller cl

e

arance

The open impeller design used by the PolyChem

GRP is set off the casing to achieve the final

operational gap. The impeller clearance was set at

the factory. (See figure 5-11.)