USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 28 of 52

flowserve.com

Figure 5-15

Flowserve coupling guards are safety devices intended

to protect workers from inherent dangers of the rotating

pump shaft, motor shaft and coupling. It is intended to

prevent entry of hands, fingers or other body parts into a

point of hazard by reaching through, over, under or

around the guard. No standard coupling guard provides

complete protection from a disintegrating coupling.

Flowserve cannot guarantee their guards will

completely contain an exploding coupling.

The coupling guard shown in figure 5-15 conforms to

the USA standard ASME B15.1,

“Safety Standard for

Mechanical Power Transmission Apparatus.”

Flowserve manufacturing facilities worldwide conform

to local coupling guard regulations.

5.5.2

ClearGuard™

- option

Flowserve of

fers as an option a ClearGuard™

which

allows you to see the condition of the coupling. (See

figure 5-16.) This guard can be used in place of the

existing clamshell guard described above. The

following instructions enable the user to properly fit

this guard to the pump and motor.

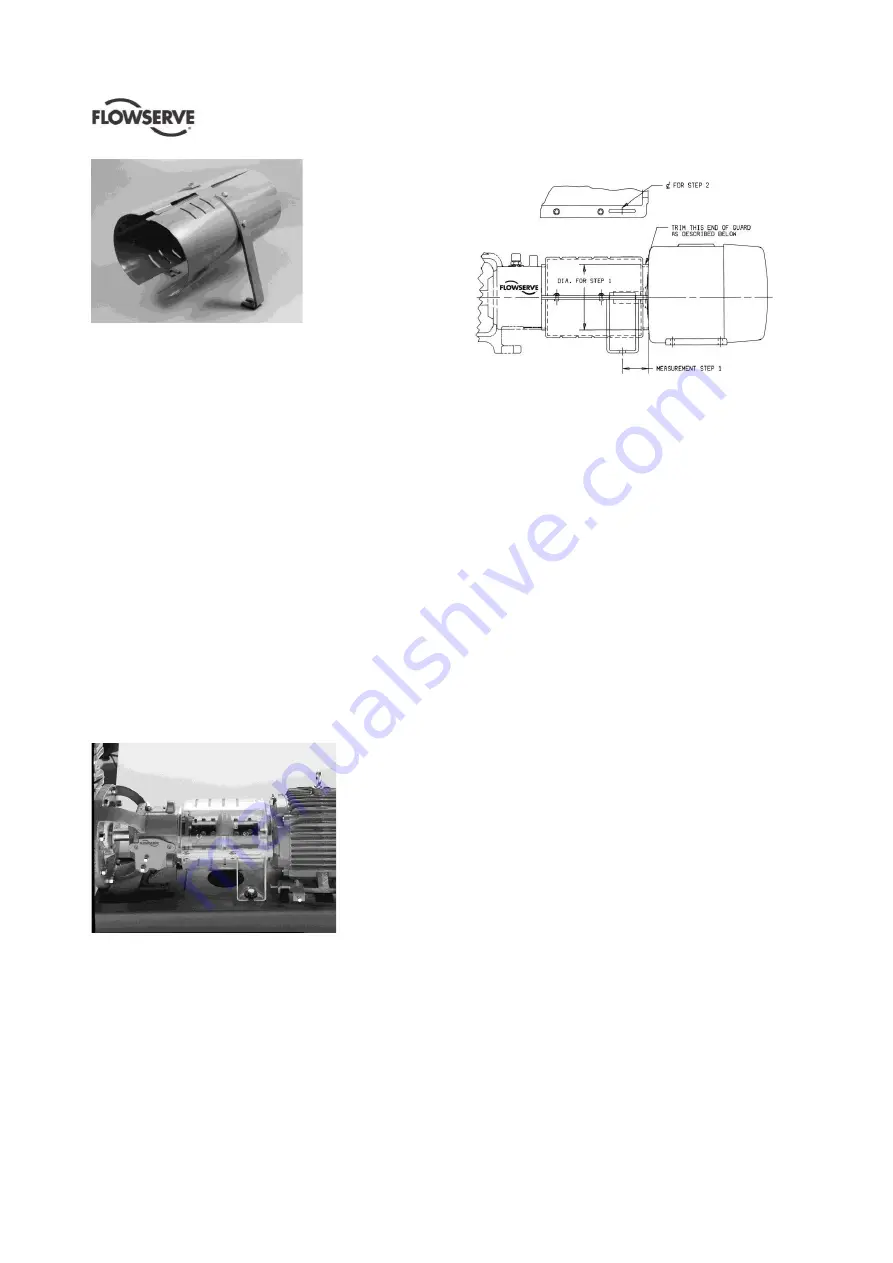

Figure 5-

16: ClearGuard™

5.5.2.1 Trimming and assembly instructions

In order to correctly fit the pump/motor configuration,

each ClearGuard must be trimmed to a specific

length. This trimming is done on the motor end of the

guard as described below. (See figure 5-17.)

Figure 5-

17: ClearGuard™

trimming

5.5.2.1a Trimming

a) Measure minimum distance from the center of

mounting hole in the baseplate to the motor at

diameter as shown above.

b) Locate a reference center of the slot in the coupling

guard flange. Transfer measurement from step 1 to

the guard using this reference center.

c) Trim the motor end of guard according to the above

measurement. Trimming is best done with a band

saw, but most other types of manual or power saws

give acceptable results. Care must be taken to

ensure that there is no gap larger than 6 mm (0.24

in.) between the motor and the coupling guard.

d) Note - if motor diameter is smaller than the guard

diameter, trim guard so that it extends over the

end of the motor as far as possible.

e) Deburr the trimmed end with a file or a sharp knife.

Care must be taken to eliminate all sharp edges.

5.5.2.1b Assembly

a) Place the bottom and top halves of the

ClearGuard around the coupling.

b) Install the support legs by inserting and then

rotating the top flange of the leg through the slot

in the shell flange until it comes all the way

through and locks the top and bottom together.

c) Attach the support legs to the baseplate using the

fasteners and washers provided.

d) Install fasteners in the holes provided to secure

the guard flanges together.

5.6 Priming and auxiliary supplies

The PolyChem GRP pump will not move liquid unless

the pump is primed. A pump is said to be “primed”

when the casing and the suction piping are

completely filled with liquid.

Open discharge valves a slight amount. This will allow

any entrapped air to escape and will normally allow the

pump to prime if the suction source is above the pump.